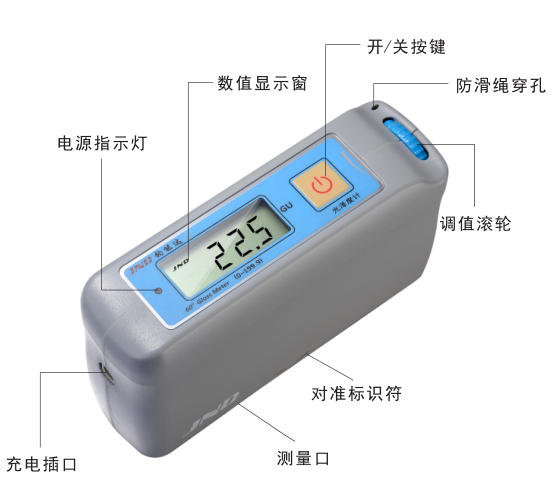

Junnengda JND-M60 Mirror Gloss Meter Operation Instructions

Junengda JND-M60 Specular Gloss Meter is a gloss measuring instrument designed and manufactured with reference to the international standard ISO 2813 and the Chinese national standard GB/T9754.

Instructions

★Power on/off

Touch the power on and off button to turn on and off the power of the instrument

★ Calibration

After turning on the power of the instrument for 3 minutes, buckle the measuring port of the instrument into the frame of the mirror calibration work plate and align it with the mark. Adjust the adjustment roller to make the display value of the instrument consistent with the verification value of the mirror calibration working board.

Tip: When the surface gloss value needs to be measured below 150 gloss units , please use the black calibration work board for calibration operation

Note : Calibration needs to be performed every time the machine is turned on!

★ Measurement

Place the measuring port of the instrument on the surface of the measuring place, and the instrument can immediately display the gloss value of the place.

Tip: The instrument should be calibrated again if it is used for more than 45 minutes. Make sure the data is accurate!

★ Check

Calibration is the self-check of the instrument by the user when there is doubt about the measured value . Calibration is not required before each measurement.

Verification instructions

The local verification is divided into two parts:

★ Calibration standard stage (suitable for measurement range 0~150 gloss units)

First use the black calibration work board for calibration operation, and then buckle the measuring port of the instrument into the white calibration work board. At this time, the difference between the displayed value of the instrument and the test value of the white calibration work board should not exceed 1 gloss unit.

★ Calibration expansion stage (suitable for measuring range 150~800 gloss units)

Reminder: The operation must be continued on the premise that the standard stage has been verified correctly .

First use the mirror calibration work board to perform the calibration operation, and then buckle the measuring port of the instrument into the black calibration work board. At this time, the difference between the displayed value of the instrument and the test value of the black calibration work board should not exceed 1 gloss unit.

Tip: If the verification result is out of tolerance, it means that the verification value of the working board has changed . In order to ensure that the measurement data is valid, please send it to the manufacturer for free re-calibration or send it to a qualified measurement institution for re-calibration.

Note: Calibration and verification must ensure that the surface of the working plate is clean and the measuring port is correctly buckled in place.

- 1Principle and Application of Glossiness Tester

- 2Working Principle and Application of Metal Gloss Meter

- 3Basic principle and application analysis of insulating paint gloss Detector

- 4Working principle and application analysis of film Glossmeter

- 5Principle and application analysis of microporous gloss meter

- 6 FZ/T 01097 Analysis of fabric gloss test method

- 7Evaluation and Application of Optical Properties of Powder coatings

- 8Coating coatings - Determination of surface gloss and Gloss meter

- 9The Importance and Method of Gloss Measurement of Paint Film