6 Things to Consider Before Buying a Temperature and Humidity Environmental Test Chamber

Temperature and humidity Test Chambers (also known as environmental Test Chambers) are designed to evaluate the quality and reliability of products under different environmental conditions, especially temperature and humidity.

Temperature and humidity Test Chambers are commonly used by researchers from different industries, such as electronics, electrical, communication, automotive, medical, aerospace, etc.

Suppose your company has a project to test a new product under various environmental conditions. You will be given an assignment to find and identify a temperature and humidity Test Chamber capable of performing the test.

how do you start What are the criteria to look out for when choosing the right chamber and supplier? Is the price always the deciding factor or the quality of your product or after-sales service?

In order to make a good decision about purchasing the right temperature and Humidity Chamber, several factors need to be considered. This article is designed to help you make an informed decision. I'm going to share 6 things you should consider before making a choice or choice.

temperature range

humidity range

temperature change rate

Internal dimensions

Products in the box

cooling method

temperature range

First, the temperature range is the main parameter for choosing a chamber. Manufacturers have wide temperature range chambers that differ in construction and insulation design. Typically, standard temperature chambers can be as low as -70°C and as high as 150°C.

"First of all, the temperature range is the main parameter for choosing a chamber"

Custom reaction chambers are available if your testing requires more than standard temperatures. Just make sure to provide your test laboratory provider with your test details. The final low temperature required for the test determines the type of refrigeration system required.

humidity range

Relative humidity (RH) depends on the water vapor pressure and temperature in the Test Chamber. At low temperatures, the system can achieve higher relative humidity with less water vapor. On the other hand, more water vapor is required to achieve high relative humidity at higher temperatures.

The standard temperature and humidity range for most Test Chambers is 10°C to 85°C with a relative humidity of 10% to 98%. There is a limit to the minimum temperature the chamber can reach due to the possibility of condensation or mist formation. The dew point of a Test Chamber is usually defined as 10°C. In the test room, the refrigerated coil should never be set at 10°C or below freezing to avoid frost formation.

"The standard temperature-humidity range for most Test Chambers is 10°C to 85°C, with 10% to 98% RH"

figure 1

The range of RH that can be achieved at a particular temperature is shown in Figure 1. For example, the minimum humidity an enclosure can achieve at 20°C is 40% RH. At a temperature of 60°C, the chamber can reach 20% RH. You need to operate the Test Chamber within the limits set by the manufacturer. Any attempt to set outside this range may result in damage to the refrigeration system.

temperature change rate

As far as temperature testing is concerned, there are different types of profiles. These tests fall into the following three categories:

1. Constant temperature or temperature cycle test

For isothermal tests, set this to the specified duration at the specified temperature. Whereas for temperature cycling tests, the temperature can be multiple temperatures for different durations.

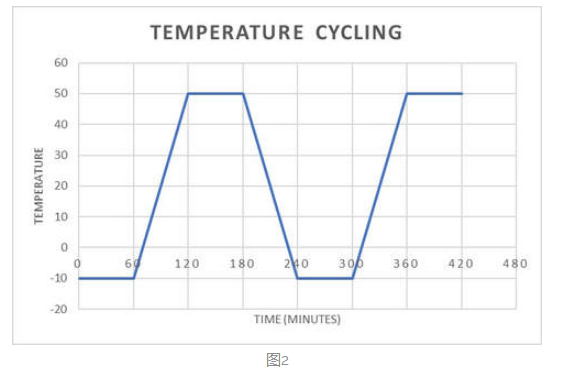

Figure 2 illustrates a typical temperature cycling test profile. Remember: the temperature change rate of heating is usually not more than 3°C/min, and the temperature change rate of cooling is usually not more than 1°C/min.

2. Rapid temperature change test

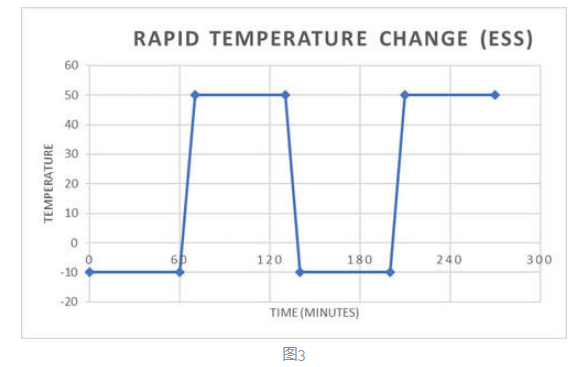

Similar to the temperature test cycle above, the rapid temperature test performs temperature changes at a higher rate (i.e., up to 20°C per minute). This test is also commonly known as ESS (Environmental Stress Screening), HALT (Highly Accelerated Stress Test) or HASS (Highly Accelerated Stress Screening). The purpose of this test is to allow you to evaluate product quality against rapid changes in temperature.

Figure 3 shows the rapid temperature change cycle test. It is important to note that the temperature of the part (specimen) is always lower than the temperature of the air in the chamber.

The chamber manufacturer will have to design the airflow inside the chamber so that the airflow has enough volume to move the air temperature at a rate close to the part temperature.

3. Thermal shock

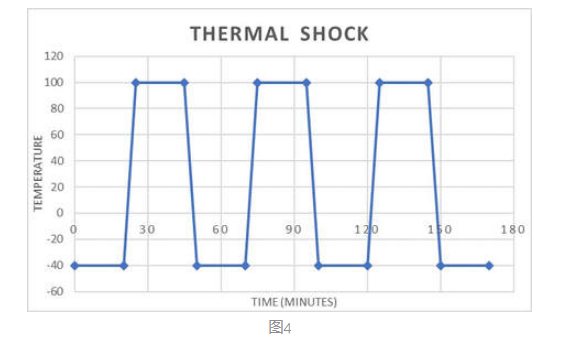

In thermal shock testing, products are repeatedly subjected to extreme low and high temperature changes with very rapid transition rates. This test stimulates accelerated stress on the product due to thermal shock during normal use.

The temperature change between low temperature and high temperature is very rapid, greater than 15°C per minute.

Thermal shock chambers are usually divided into 3 zones or 2 zones

For a 3-zone thermal shock chamber, the chamber consists of a high temperature zone, a low temperature zone and a test zone. The product is placed in the test area and hot and cold air is blown alternately from each chamber.

Some equipment uses 2 separate hot and cold chambers (2 zones) with a lift mechanism for the product transiting between these 2 compartments.

Internal dimensions

Box dimensions are always ignored by buyers. Most people mistakenly think that indoor performance does not depend on the space, as long as the product can fit in the indoor, no matter the size of the product.

It is important to know that the chamber needs to have sufficient air volume to ensure effective airflow. Therefore, it is better to get a chamber slightly larger than to buy a chamber that is too small.

Wide range of sizes and dimensions can be customized according to your requirements. Chamber sizes can range from small benchtop chambers to walk-in chambers.

cooling method

The air in the chamber is cooled by a refrigeration system. The heat extracted by the refrigeration system is dissipated through the condenser.

There are two main types of condensers: air-cooled or water-cooled. Each has its pros and cons.

Small chambers often have air cooling as standard. This configuration is very convenient in terms of mobility and space saving, since the air-cooled condenser is built into the chamber.

But, on the other hand, the heat is dissipated into the room where the chamber is located. Thus, the air conditioner in the room needs to be able to handle the additional heat load generated by the chamber.

Second, you need to pay attention to the dirt around you. Since the condenser is located near the floor, it tends to pick up dust. Therefore, regular cleaning of the condenser is necessary.

If the chamber is to be placed in a dirty environment, water cooling may be a good solution. In a water-cooled system, the condenser is usually placed outside.

Still, water cooling systems are more complicated and expensive to install. This type of system requires refrigeration piping, water tower installation, electrical wiring and water works. As you can see, the installation can be messy and cost you extra.

Summarize

As a conclusion, there are many different types of Test Chambers in use. Determining the type of chamber required requires a clear understanding of your application.

What is required is that testing and product information be communicated to suppliers in as much detail as possible.

What is the required chamber size? What is a sample? What temperature or humidity range is required? Is the chamber air-cooled or water-cooled?

These are the basic questions you need to ask before purchasing a temperature and humidity testing chamber.