What is hardness testing? What types are there?

Hardness testing is a quality test used in foundries to measure the properties of cast metals and their suitability for different applications. Its popularity is due to the non-destructive nature of the test and its relationship to other mechanical properties. The foundry infers the tensile stress of the material from the hardness test results.

The properties of cast metals vary according to the composition of the metal, process conditions and heat treatment. It is important to certify cast metal products suitable for the desired end application. Four main categories of properties are important to cast metal users:

strength

Influence

hardness

Corrosion resistance

Foundries sometimes cast test panels during product casting. The quality test results of the test pieces were also considered to be correct for the castings. Certain tests, such as tensile stress and impact, can destroy test pieces in the process. However, non-destructive testing (NDT) does not destroy metal samples to obtain results. The advantage of NDT is that, as opposed to test pieces, tests can be performed on the cast metal product itself.

Benefits of hardness testing:

Ability to verify heat treatment of parts during heat treatment operations and in-depth analysis of cases

Ability to determine whether a material has the properties necessary for its intended use

Non-destructive testing alternative to efficiently verify and release materials or components in target applications

low cost and fast performance

What is hardness testing?

The term "hardness" generally means resistance to deformation. For metals, properties are a measure of their resistance to permanent or plastic deformation. Several different tests exist for measuring the hardness of metals and cast metals.

Brinell hardness test

Brinell hardness test method ASTM E10-Standard test method for Brinell hardness of metallic materials. The American Testing and Measurement (ASTM) is the custodian of this standard. This is a macro indentation test in which a high load is used for the measurement. Cast metals require macro hardness testing due to their coarse grain structure and potentially inhomogeneous material.

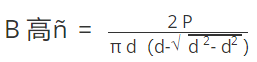

To obtain a Brinell Hardness Number (BHN), a carbide ball of fixed diameter is pressed into the metal under a fixed pressure for a set time. After removing the load, the operator will measure the diameter of the indentation left and convert it to BHN using the following formula:

P = applied force (kgf)

D = indenter diameter (mm)

d = indenter diameter (mm)

In the United States, the test load for steel and iron is usually set to a maximum of 3000kgf for a 10mm steel ball. Aluminum uses a lower test load of 500kgf and sometimes a smaller indenter of 5mm. Typical BHN ranges for metals are 50-750. The following Engineering Toolbox Brinell hardness tables list some examples of BHNs:

For Brinell hardness testing, the preparation of the metal surface is very important. Jagged surfaces or other imperfections can affect results. Grinding of metal surfaces in preparation for testing is recommended to better reduce variability in results.

The origin of the Brinell hardness test dates back to 1900. In the early days of testing, results were strongly influenced by the operator's perspective. Different operators give different results, leading to high variability in measurements. However, with the introduction of electronic measuring equipment, the level of consistency has increased considerably.

Rockwell hardness test

Rockwell Hardness Test Method ASTM E18 - Standard Test Method for Rockwell Hardness of Metallic Materials. The Rockwell test has two phases. The device applies a preliminary test force to the sample using a diamond or spherical indenter. The purpose of this stage is to break through the metal surface and reduce the effect of the surface finish on the final result. The operator now measures the baseline indentation depth. After holding the preload for a set period of time, a major load is applied. Also, hold the force for a preset period of time before reducing it again to the preload force. After the time has elapsed, the operator will take a depth measurement of the indentation. The Rockwell hardness value is based on the difference between the baseline and final depth measurements.

For the accuracy of the Rockwell test axis, the perpendicularity of the test axis needs to be within 2 degrees. A Rockwell hardness scale is carried out with the test.

N = constant

S = scale unit

h = pressing depth

Leeb hardness test

The Leeb test uses ASTM A956 - Standard Test Method for Leeb Hardness Testing of Steel Products. The Leeb test is a measure of the rebound of an object from a test sample. The hardness of the metal affects the rebound energy - a harder material will have a greater rebound, while a softer material will dampen the rebound energy. The velocity of the object before and after impacting the sample forms the basis for the rebound value. The Leeb test apparatus consists of a coil that measures the induced voltage of a magnetic ball used for rebound testing. This induced voltage is directly related to the speed at which the ball passes through the coil of the test equipment.

Advantages of the Leeb method include leaving much smaller indentations on the test sample than other methods. It is also portable, easy to use and faster than Brinell and Rockwell Hardness Testers. The disadvantage is that variable results may be produced where the sample surface is uneven. The thickness and carbon content of the sample may also affect the results.

Hardness value conversion

ASTM E140-12be1 provides a standard hardness conversion table for metals that can be converted from one hardness test method to another. It is important to note that these transformations are approximate and depend on factors such as material composition, microstructure and heat treatment. Although these tables are based on extensive testing by different methods, the conversion results should only be considered as estimates of comparable values.

Hardness value and heat treatment

Cast metals are heat treated to control their properties. Heat treatment involves raising the temperature of a material to a predetermined value. It is then cooled at a specific rate based on the desired properties of the product. The final temperature and cooling rate of the heating cycle directly affects the microstructure of the metal.

The fine pearlite and ferrite microstructures caused by faster cooling rates have larger hardness values. If the metal is quenched, the rapid cooling will result in a martensitic microstructure, which is very hard. Since there is a direct relationship between microstructure and hardness, hardness testing can quickly indicate whether the heat treatment was successful.

Hardness Values and Cast Metal Properties

The table shows the relationship between tensile strength and hardness for specific materials. This is a useful correlation because measuring tensile stress is a destructive process whereas hardness testing is non-destructive. However, there are limitations to the conversion from hardness to tensile strength and these tables are only approximations.

Hardness testing in foundries

The development of hardness testing has made it easier for metal foundries to evaluate the performance of their products based on one simple test. It is non-destructive, which means it can be done on the finished product without causing damage. This is a fast process that provides the foundry with quick feedback on the product as it leaves the production line. The correlation between hardness values and tensile strength is a useful guide for initial assessment of product grades. Foundries complete a full suite of certification tests before releasing products to customers.

Hardness testing also helps foundries check their heat treatment processes. The results indicate whether the material's microstructure has changed as expected. Hardness testing is a key component of quality control and process adjustment in metal foundries.

-

-

-

-

-

-

-

Leeb Hardness Tester DHT-100Dplus$ 1312.00

-

-

- 1Read the Leeb Hardness Tester in one article

- 2Leeb Hardness Tester different hardness system difference

- 3What products is the Leeb Hardness Tester with D probe suitable for measuring?

- 4Basic knowledge of hardness testing

- 5Factors Affecting the Accuracy of Leeb Hardness Tester Testing

- 6Leeb Hardness Tester measurement requirements

- 7Factors Affecting the Test Accuracy of Leeb Hardness Tester

- 8What are the measurement requirements for a Leeb Hardness Tester?

- 9What factors affect the test accuracy, error and repeatability of the Leeb Hardness Tester?

-

-

PRLH150 Leeb Hardness Tester$ 259.00

-

-

-

-