Application of Lacquer Film Impact Tester in Testing Adhesion Level of Enamel Coatings

The level of adhesion of an enamel coating cannot be judged directly by its surface appearance. The interior is hidden thanks to the combination of enamel coating and steel. And Nolifrit has a very specialized method for testing the adhesion of enamel coatings.

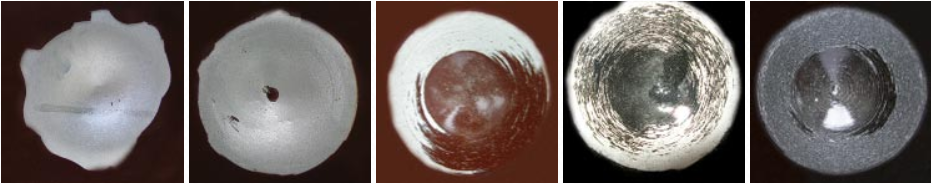

Impact Tester Test Principle Due to free fall, the test weight creates a cavity in the enamel-coated surface. The enamel in this area was cracked and the impact of the impact was checked visually. The impact effects are rated according to the scale below. Record this result as the Adhesion Value for the Enamel. The test method uses the impact Tester on the picture. The impact device has a specific diameter with a specific weight and a spherical tip. The enamel-coated plate is placed on a ring metal mold. Structural Specifications A pipe with a length of 1 meter and an internal diameter of 21 mm is placed completely vertically on a suitable rack. The channel opens on one side of the pipe. To fix the weight, several sections are placed at different heights of the pipe. T The weight of the impact device inside the pipe is 2 kg. The tip of the device is designed as a hemisphere with a diameter of 10 mm. Adjust the distance between the end of the pipe and the metal mold so that the power of the vertical load weight does not drop. The distance between the impact weight and the metal plate to be tested is 0.75 m. The impact site was released from this location, so the impact energy was determined to be 15 kj. Impact energy = drop height X impact weight X gravity constant.

5 too weak 4 weak 3 medium 2 good 1 excellent

- 1What is impact testing?

- 2What is the difference between the internal and external performance requirements of granite coatings?

- 3HG/T 5573 Graphene zinc powder coating performance testing scheme [with economic file instrument parameters]

- 4Three different test methods for impact resistance of coatings

- 5Polyvinyl chloride film experimental testing instrument scheme

- 6How to test the impact resistance of coatings?

- 7TQC Paint Film Impact Tester Operation Instructions

- 8Paint film impact meter to determine the bonding strength of coating

- 9Paint film impact meter related testing standards