Selection method of Brookfield online viscometer

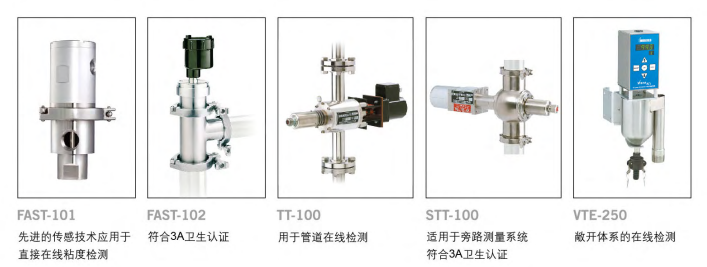

AMETEK Brookfield manufactures in-line viscometers with the same very high standards of performance and value as laboratory viscometers. In addition, we pay special attention to the long-term durability and ease of maintenance required by the instrument for industrial environments.

1. What is the viscosity range of your product?

2. What type of fluid is your product, Newtonian, dilatant, non-Newtonian, thixotropic or plastic fluid?

3. What is the minimum, maximum and average pressure you applied?

4. What are the minimum, maximum and average temperatures for your application?

5. What are the minimum, maximum and average flow rates for your application?

6. Where would you like to mount the viscometer: in a pipe, on top of a vessel, or on the side of a vessel?

7. What is your requirement for the electronic unit?

NEMA1 (general purpose, indoor installation)

NEMA4 (waterproof/dustproof, indoor or outdoor installation)

NEMA7 (Explosion-proof - Class1, Div.1&2, Group D)

ATEX (explosion-proof type-code: Exd11BT6)

Some models do not necessarily have the above parameter indicators, for example, when the viscosity of the object is higher than the measuring range of the instrument or outside the rated pressure of the instrument. In many cases, it may be necessary to use several instruments at the same time.

AMETEK Brookield can help you select the proper viscosity control system to meet your application requirements.

- 1Online Viscometer Selection Guide

- 2What are the advantages of in-line viscometers for viscosity testing?

- 3Online Viscometer should be used correctly!

- 4Structure of Online Viscometer

- 5Testing Principles for Online Viscometers

- 6Nerun teaches you how to properly maintain an online Viscometer?

- 75 points to note when using online Viscometers

- 8Brookfield Online Viscometer Application in Oil/Gas Fields

Brookfield