Application of gloss meter in detection of impurity gloss

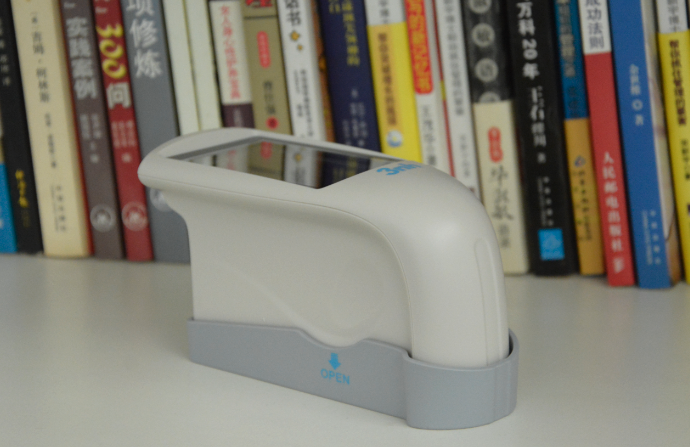

Consumer magazines are everyday media commodities, ubiquitous in urban environments in developed countries. Magazines disseminate popular culture and surround it in the form of cultural merchandise. It is seen as both an object and a sign. Consumer magazine text places a heavy emphasis on photography, colour, illustration, visual effects and a general reliance on aesthetics. The magazines are bright and glossy, representing pleasure and relaxation rather than seriousness. The smell and feel of glossy paper signifies luxury. The medium is characterized by iconic, stylized and well-designed covers with all the colours, illustrations, photography and sensual touches throughout the magazine. Digital Gloss Meter is a testing instrument used to measure the gloss of paper, plastic, the brightness of paint, etc.

Gloss is the theory of smoothness that finds microscopic substance. Two types of paper are used in batch printing, coated or glossy and uncoated or matte. Most magazines are printed on lightweight coated paper, while covers are printed on heavier paper, which is a more expensive, glossy paper. Gloss is measured relative to its ability to reflect light. This coating enhances ink retention and visual impact of images. Glossy paper was chosen for technical reasons in order to achieve a high visual impact in terms of image reproduction and colour. Glossy papers create a sense of luxury and quality that uncoated papers do not. Light is the main element in the mechanics of gloss, both in terms of manipulation of lighting and reflectivity and in terms of color mediation of light.

Gloss is an aspect of the visual perception of an object and as a color is very important when considering the psychological impact of a product on consumers. The gloss of a surface is influenced by many factors such as the smoothness achieved when polishing, the amount and type of coating applied. Manufacturers create products that gain a lot of appeal, such as glossy magazine covers, black designer furniture, and more. It can be used to measure surface quality, such as a drop in gloss on the surface of a coating indicating curing issues. This can lead to various other failures, such as poor adhesion or lack of protection for the coated surface.

The three-angle gloss meter can measure the glossiness of the material surface from three angles. They are 20 degrees, 60 degrees and 85 degrees. It helps to measure the correlation between gloss and gloss when the sample is laid flat.

- 1Gloss inspection method of slurry inks

- 2Principle and Application of Glossiness Tester

- 3Working Principle and Application of Metal Gloss Meter

- 4Basic principle and application analysis of insulating paint gloss Detector

- 5Working principle and application analysis of film Glossmeter

- 6Principle and application analysis of microporous gloss meter

- 7 FZ/T 01097 Analysis of fabric gloss test method

- 8Evaluation and Application of Optical Properties of Powder coatings

- 9Coating coatings - Determination of surface gloss and Gloss meter