What is the Vickers hardness test? How to test Vickers hardness?

How many times have you wondered if the material you need for your project is hard enough for its intended purpose? Hardness is a critical property for many applications. Fortunately, there is a relatively easy way to measure the hardness of a material called the Vickers hardness test.

According to the Metals Handbook, hardness is defined as "resistance to plastic deformation". Since different materials behave in different ways, there are generally three types of hardness measured. According to the material, they are:

Indentation hardness

Scratch hardness

Rebound hardness

Vickers hardness testing measures the indentation hardness of small parts or thin sections of metals, ceramics and composites - virtually any type of material

What is the principle of Vickers hardness test?

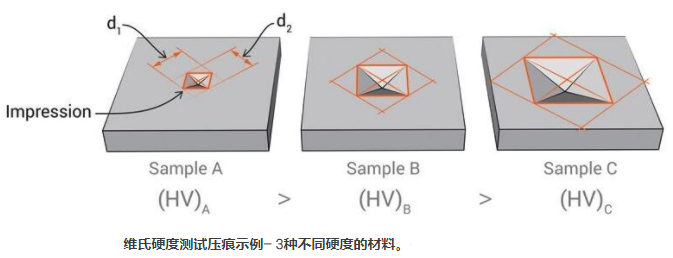

The test involves applying a force (also called a "load") on the test material using a diamond indenter to obtain an indentation. The depth of the indentation on the material gives the hardness value of the sample. In general, the smaller the indentation, the harder the object. Hardness testing can be divided into microindentation testing and macroindentation testing, depending on the force applied to the test material. (Microindentation tests typically use loads up to 200 gf, while macroindentation tests use loads up to 1000 gf). Vickers hardness test and Knoop hardness test are commonly used tests for micro-indentation and macro-indentation.

Why Use the Vickers Hardness Test?

Originally designed as a replacement for the Brinell indentation method, which has the larger indenter and potential for damage to the test piece, and as a replacement for the Rockwell method, which uses multiple test forces; the Vickers hardness test is easy Use, compared with other hardness tests, has many advantages, such as:

The indenter size used is smaller, reducing the risk of possible damage to the test material

Indenters can be used on any type of material, regardless of hardness

The calculated results are independent of the size of the indenter

It has a very wide scale compared to other hardness tests

Apply a single test force

How to measure hardness?

The test is performed by pressing a diamond indenter into the surface to be tested. The indenter is pyramid-shaped, with a square base and an included angle of 136 degrees between opposite faces. Typically, the load range is from 1 to 100 kgf. A full load is usually applied for 10 to 15 seconds.

The lengths of the two diagonals formed on the test surface are measured and the average value is used to calculate the hardness, which is given by the ratio F/A (where F is the force or load in kgf; and A is the specimen surface area). indentation in square millimeters). Hardness values are expressed as Vickers hardness (HV) or diamond pyramid hardness (DPH) (usually a number without units).

Measurements are taken using the built-in microscope. Some more advanced test scales use software to achieve faster and more accurate results.

Application field

Vickers testing produces relatively small indentations and is therefore very useful for testing the hardness of small parts or sections and very thin objects such as foils.

Precautions

In order to obtain accurate results from the test, it is better to consider the following points:

Choose a sample small enough to fit on the scale

Smooth the surface of the test material to achieve proper indentation and better reduce measurement errors. Also, this helps keep the material perpendicular to the indenter

Make the indentation as large as possible for better measurement accuracy (as the indentation size decreases, the chance of error is higher)

limitation

For all its advantages, the Vickers hardness test has its own limitations. Critics argue that, at lower loads, there will be some degree of deflection. Some test materials are pre-coated, in which case the thickness of the coating affects the accuracy of the microindentation measurement. To overcome this problem, advances in the field of nanotechnology have led to the development of nanoindentation methods.

- 1What is the principle of the Vickers test?

- 2The principle and subdivision type of Vickers Hardness Tester

- 3Learn the basics of Vickers hardness testing

- 4Comparison of six hardness test methods of Vickers, Rockwell, Brinell, Mohs, Shore and Knoop

- 5Microindentation Hardness Testing Principle and Its Typical Applications

- 6How to test the hardness of copper?

- 7Why use the Vickers hardness test?

- 85 Ways to Measure Material Strength

- 9What is the Vickers hardness test?