Why can't Zahn Viscosity Cups be used for viscosity measurement of thixotropic fluids?

Thixotropic material

It turns out that, in addition to kinematic and dynamic viscosities, fluids fall into two categories to describe their viscous behavior: Newtonian and non-Newtonian. But the difference in these appellations describes the definition of thixotropy – so let’s start there…

Newtonian fluids are those fluids whose viscosity does not change with shear. While water is usually mentioned, another good example is motor oil, where you want to maintain its viscosity under shear stress (for example, between two metal parts such as a piston ring and a cylinder in an engine, To provide lubrication to keep the oil lubricated. Parts wear each other out.

On the other hand, the viscosity of non-Newtonian fluids changes with the applied shear force. That accounts for almost everything else! Virtually all coatings, sealants, adhesives and other complex formulated liquids used in modern industrial processes exhibit "shear sensitivity".

What is shear force?

When a force is applied to a fluid, shear occurs in the fluid. That force could be the pull of gravity (as in the water and honey example in part one of this series), or the force from the piston, vane, or impeller of a pump when we force fluid through a pipe or hose. Shear forces are also created on the wall of the pipe or hose when fluid from the outside adheres to the inside surface while the rest of the fluid flows through it on the inside. Fluid is also "sheared" when it passes through an orifice, such as in a pressure regulator, or in the nozzle of a spray head such as a Spray Gun or bell, or in the orifice at the bottom of a Zahn cup.

For thixotropic shear-thinning fluids, as stress or shear increases in the fluid, its viscosity decreases.

It might be easier to understand the whole concept with a visual example. Figure 1 shows the properties of a Newtonian fluid. We can see that the viscosity of the fluid remains constant even though the shear force is increasing.

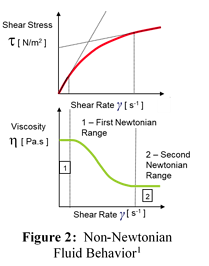

However, the behavior of non-Newtonian fluids is a bit more complicated. As shown in Figure 2, the shear curve (shown in red in the top plot) increases in a non-linear fashion. It grows faster at the beginning and levels off towards the end. This is very typical in industrial fluid distribution processes. But what's really interesting is that as the shear increases, the behavior of the fluid increases as shown by the green curve in the bottom plot.

For convenience, it is divided into areas to make it easier to understand. Region 1 (first Newtonian range) shows viscosity when the shear level is low. Under these conditions, the viscosity remained stable. But as the shear increases, it starts to affect the thixotropic material, and we see a sharp drop in viscosity in response to shear in the transition range. This is an inversely proportional response, but has its limitations. A point occurs, marked by entering zone 2 (the second Newtonian range), where increasing shear no longer has an effect on the viscosity of the fluid.

The problem arises when you try to operate the process in the transition region between the two Newtonian ranges. Here, small changes in shear can cause considerable changes in viscosity, which can seriously affect the outcome of the process.

Recovery Time

Suppose your material is a coating, sprayed onto the part through an orifice. When spraying, the shear force created by the orifice reduces the viscosity. The low viscosity allows the fluid to "bleed" easily when it hits the part. But at this point there is no longer any shear force on the fluid. As a result, it climbs back up the curve in the transition range to higher viscosities in the first Newton range, at which point the outflow virtually stops. This is called "recovery". It is the return of the fluid to its "non-shear" state. The time this process takes is called "recovery time" and can be measured in seconds, minutes, or even hours in some cases.

So, how does all of this relate to cup measurements?

cup measuring process

The basic cup measuring process is very simple. The cup is fully submerged in the liquid and pulls straight up to remove. The time it takes for the fluid to drain from the cup defines the viscosity in "cup seconds".

Seems easy enough, right? However, there are many problems associated with this simple process.

When do I start the clock? When did the top of the cup break the surface? When does the bottom of the cup clear the surface?

when do i stop When was the stream first interrupted? When it breaks down into droplets? When is the glass empty?

And, if the cup is not straightened up, it will affect the flow through the hole by transferring the pressure on the hole to the wall of the cup. So, what is straightness?

The Physics Behind Cupping Measurements

The cup is full when it is withdrawn from the liquid. The liquid in the cup exerts a force on the fluid at the hole due to gravity. There is also the weight of the atmosphere pressing on the surface of the fluid, but this is a constant for any given position (mainly due to height) and kind of cup (volume, diameter, hole size, etc.), so we can ignore in our discussion.

The fluid is "forced" through the hole as gravity pulls the fluid downward. As a result, some shear forces are introduced into the fluid. But this "force" is determined by the volume in the cup and decreases over time, which means that the force on the fluid passing through the hole also decreases over time. As a result, the shear on the fluid is also reduced.

The next really important question is: "Is there enough force/shear to adequately shear the material?" This means moving it through the first Newton range, the transition range (in the middle) and into the second Newton range, Sufficient to achieve a stable viscosity. If you're considering the amount of liquid in the cup, the size of the orifice, the time it takes to get the liquid to flow through that orifice, and think it's unlikely we'll get out of the first Newton range, let alone reach the second Newton range.

So what if the shear force does go through the first Newton range, but falls somewhere in the intermediate transition range? You would be correct if you said that the measurements are unstable and unreliable due to the interaction between shear and viscosity. This is another reason for variations in cup measurements - through absolutely no fault of the operator.

Why do my cup measurements not match the automatic viscometer?

This is a common problem faced by almost all viscometer manufacturers (no, we are not alone, and yes, we do talk!) However, after discussing it, it is easy to understand that automatic viscometers measure by measuring the force required viscosity. Introduce shear in the fluid – just like how Newton originally defined viscosity. It is much easier for a mechanical viscometer to introduce shear forces into a fluid than gravity.

Another interesting fact is that most viscometers are calibrated using Newtonian fluids - calibration standards are designed to behave (read: viscosity) very consistently and predictably over shear and temperature ranges. If both a mechanical viscometer and a cup are used to measure a Newtonian fluid, the measurements will be very close - since shear is not a factor. But non-Newtonian fluids are a very different story.

When is viscosity measurement useless?

This seems like a silly question considering the known effect of viscosity on the outcome of our fluid dispensing process. But in reality, many of the viscosity measurements we make are useless.

So when is a viscosity measurement useless?

What if measuring the viscosity of a fluid under conditions different or even out of reach from what the fluid will encounter in our process! Given our discussion of Newtonian and non-Newtonian fluids and the effect of shear on our measurements and process results, it is easy to conclude that cup measurements rarely replicate modern process conditions.

So why measure cups?

Now, you're probably back where we started and asking yourself, "If this is all true, why does everyone need to rely on Viscosity Cup measurements to manage the process?"

Cup measurements have been around for a long time, much longer than the complex fluids most of us work with today. And, compared to sophisticated measuring systems, cups are cheap. And the cup takes no more than a minute or two to read, so it's cheap to measure.

-

TQCsheen VF2199 Lory Viscosity Cup$ 457.00

- 1Coating viscosity determination - viscosity cup Yiwen

- 2Principle, application and selection of ZAHN5 viscosity cup

- 3Corrugated fibreboard starch viscosity cup its principle, application and selection introduction

- 4Decryption paints original juice viscosity cup, principle, application and selection

- 5Wood lacquer viscosity cup, principle, application and selection introduction

- 6Analysis of the principle, use and application of Ford6 viscosity cup

- 7Principle, Structure, Usage and Application of QNB Viscosity cup

- 8Introduction to the use and application of No. 4 viscosity cup

- 9Coating viscosity determination by Flow Cup method