How do oven conditions affect powder coating performance?

Powder Coating Properties

Most powder coatings are thermoset in nature, meaning that an irreversible chemical reaction occurs during curing in the oven. The degree of cure has a major impact on the final properties of the finish. The degree of curing of the powder will affect the appearance characteristics and durability of the coating.

Gloss

Low-gloss and matte powder coatings are usually formulated by controlling the curing reactions of the various components in the formulation. This is a common technique used by formulators to create very smooth but low gloss finishes. Therefore, insufficient curing can lead to changes in gloss. This is common with hybrid powders and epoxy powders, but can also be observed in certain polyester and polyurethane formulations. Therefore, the importance of managing oven conditions when curing matt and low gloss powders cannot be overemphasized. If the gloss of the part is higher than expected, the powder coating may be undercured. In most cases, you can re-bake the part and the gloss will drop to the specified range.

Mechanical behavior

One of the unique features of thermoset powder coatings is that the coating can "look" cured, but not under-cured. Liquid paints are inherently easier to identify undercured as they may become tacky or soft if not seen for sufficient time and/or temperature. Powder Coating Finishes Are Still Difficult

Retains tactile feel even when undercured. Incomplete curing usually results in mechanical properties with a poor finish. The coating becomes brittle; therefore, adhesion and chip resistance may be compromised. This is usually found when parts are being assembled and the surface is cracked or chipped when the parts are fastened. Even worse, if parts leave your facility and are assembled in a different location or placed on site. Numerous mechanical coating failures can occur which can lead to costly repairs and/or product liability claims

Coating Durability

Prime curing of powder coatings not only compromises the mechanical properties, but also the ultimate durability of the coating. Incomplete crosslinking results in reduced corrosion resistance, reduced resistance to chemicals and solvents, and poor outdoor durability. Therefore, the importance cannot be overemphasized to ensure a complete cure.

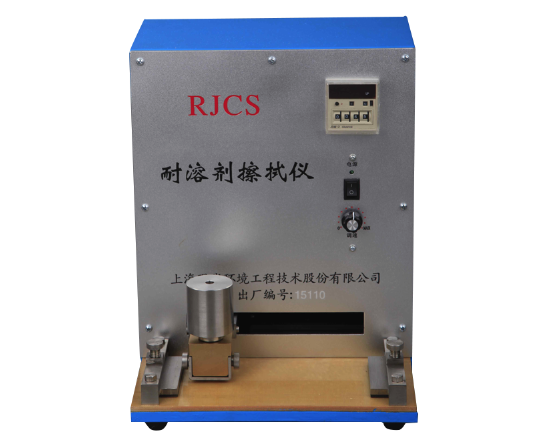

One of the common tests involves evaluating the solvent resistance of coatings (testing instrument: Solvent Wipe Tester). ASTM D5402 describes the test. Basically, you use a rag or swab soaked in acetone (or methyl ethyl ketone) and wipe the surface 25 to 50 times. Your powder coating supplier will be happy to advise you on the appropriate number of rubs for your coating. In some cases, less aggressive solvent mixtures such as 90% xylene/10% MEK are recommended for this test. Depending on the chemistry of the paint, a fully cured powder will soften slightly through the solvent rub test, but will not dissolve and transfer the paint to a shop rag or cotton swab.

Effect of Oven Conditions on Powder Chemistry

Coating formulations have a significant impact on how a product behaves in the oven. A summary of properties that are particularly affected by the degree of hardening.

Volatile

The volatile content of thermoset powder coatings depends on the formulation and chemistry. All powder coatings emit approximately 0.5% to 1.0% water during baking. Another small fraction of organic volatiles is also expelled from the coating. These are usually additives and low molecular weight fragments of the resin. Epoxies, hybrids, TGIC polyesters, and most acrylics emit only small amounts of volatiles and therefore do not cause significant oven venting or fouling issues.

To evaluate the solvent resistance of a paint, wipe the surface 25 to 50 times with a rag or swab soaked in acetone (or methyl ethyl ketone)

During the crosslinking process in the oven, some chemicals emit so-called curing volatiles. Most notable are most polyurethanes and HAA (hydroxyalkylamide) polyesters (aka non-TGIC or Primid™ polyesters). For polyurethanes, a common blocking agent, ε-caprolactam, is emitted during oven curing. This manifests itself as smoke in the oven, where emissions can be as high as 5% of the paint weight. Proper oven venting is necessary to better reduce the build-up of this volatile in the oven. Insufficient venting can lead to fouling of the oven, which can cause color instability in the powder coat. Additionally, the epsilon caps can condense on the interior surfaces of the oven and exhaust pipes, further causing cleaning issues and possible flammability issues

In addition to the ambient moisture present in typical powder coatings, HAA polyesters also release water as curing volatiles. Although thicker than normal membranes, this discharge is relatively harmless and easily exhausted, although pinholes will appear from escaping water molecules

curing reaction

While it is self-evident that it is important to ensure that parts are subjected to sufficient time and temperature per the recommendations on the product data sheet, some chemicals cure significantly differently than others. Epoxies, hybrids and TGIC polyesters are very insensitive to changes in cure response. Adequate curing with these chemicals can usually be achieved in an oven at slightly lower temperatures than specified for extended periods of time. Polyurethanes react quite differently. For these products, a minimum temperature is necessary to initiate any cure and therefore coating properties. Typical polyurethanes require at least 350°F for the curing reaction in the coating to begin. Oven conditions below 350°F will cause the coating to melt and flow without any meaningful curing, thus resulting in poor coating performance.

HAA polyesters were also more sensitive to curing conditions than TGIC polyesters, epoxies and hybrids, but not to the extent of polyurethanes. Typical HAA polyesters require a minimum cure temperature of at least about 325°F or higher to initiate cure. Therefore, monitoring part temperature with these products is even more critical.

The advantage of a data logger is the ability to determine the temperature profile of multiple parts and/or part locations under the same conditions.

color stability

Epoxies tend to exhibit the least color and overbake stability. Especially noticeable with white and light colors. Hybrid materials are better, polyurethane and TGIC polyester have good color stability over a certain temperature range. Low temperature curing powders have less color stability than standard baking powders because they contain catalysts to enhance accelerated curing. HAA polyesters are more prone to yellowing than TGIC polyesters.

As you can see, not all powder coatings are created equal, and each responds to oven conditions in its own unique way. The importance of oven settings, including part density and loading, to achieve adequate cure and acceptable coating performance cannot be overemphasized. Therefore, it is necessary to know your powder coating product and set and monitor oven parameters to ensure consistent quality and coating performance

- 1Principle, application and selection of Electric Oven

- 2Principle, application and selection of Electric Oven

- 3Principle, application and selection of ozone sterilizing oven

- 4Principle, application and selection of tunnel oven

- 5Working principle and application analysis of laboratory oven

- 6Determination of thermal plasticity Resin melt flow rate

- 7Molecular weight and distribution characteristics of polyester resin in thermosetting powder coatings

- 8Density Determination Method and Application

- 9Determination method of cone-plate viscometer and its application