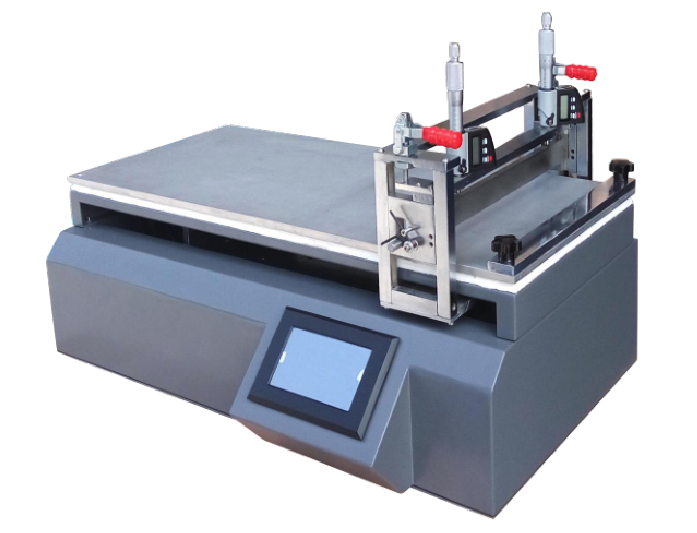

Instructions for use of Kimpt small automatic coating machine

overview

Laboratory automatic coating machine is a new laboratory instrument developed in recent years. It is a successful innovation of the organic combination of electrical control and machinery. In the field of coating production, it can save raw materials and improve production technology. The key is to greatly improve the reproducibility of coating on the basis of experiments.

In the past, manual coating was mostly used in general coating experiments, and the coating was uneven and the overall effect was poor. In order to solve these problems, the laboratory coating machine was born, and its appearance can be said to be the icing on the cake for the booming coating industry. The function of the laboratory coater is to facilitate the accurate coating on different substrates by the experimenters, reduce and eliminate the errors caused by human factors such as different . It is mainly used for production experiments of metal foil, glue, paper, and film , and can also be used for other related coating and coating industries.

Coating machine principle and characteristics

This product is carefully designed according to the requirements of small-scale coating tests. The product strives to be reliable and easy to operate.

Its basic coating principle is as follows: The coating system is mainly composed of a speed-regulating motor, a screw, a sliding shaft, a handle, a scraper, a meter and other mechanisms. The coating thickness is adjusted by the trimmer, and the coating speed is set by the speed control knob uniform coating.

Coating test machine installation

1. It is better to unpack the machine at the installation site. Before unpacking, check whether the packing box is damaged; after unpacking first check whether the equipment is in good condition, and check it according to the packing list . Analyze the situation and immediately report to our company in writing.

2. The installation location of the machine should be selected in a place where there is no source of vibration.

3. The machine should be installed on a flat and solid foundation, and check whether it is flat with a level meter.

4. Turn off the main power switch of the machine before turning on the power, check whether the power connection is correct, and turn on the power after checking.

5. The bottom corner of the machine should be placed on a solid table, and the bottom corner should not be suspended.

6. Turn on the power and turn on the switch.

Automatic coating machine commissioning and operation

The boot operation screen enters the [Welcome interface]

Click any point on the [Start Interface] to enter the [Operation Interface]

Set the corresponding parameters to test

Heating operation: (the standard model has no heating unit, and the temperature item does not need to be set)

1. Temperature setting

Click [Set Temperature] on the screen to input the desired temperature, and click [OK] to complete the setting.

2. Heating

Click [Heating] on the screen, and the indication value of [Measured Temperature] starts to jump, and the instrument starts to heat up. When the temperature reaches the set temperature, the instrument automatically stops heating. When the temperature drops below the set temperature, the instrument starts to automatically heat up again.

3. Stop heating

You can click the [Heating] button again at any time during heating, and the displayed value of [Actual Temperature] will stop beating, and the heating will stop. After the test , click [Heating] to stop heating.

Please note: It is forbidden to touch the working surface during the heating process of the instrument, and pay attention to prevent burns. The residual heat during heating will make the temperature higher than the set temperature, and the equipment will automatically stop heating and cool down. After reaching the set temperature for 5 minutes, the test will start when the temperature is stable.

Blade coating test method

1. Zero adjustment

1.1. Put the material to be coated in the clamp and tighten the two ends to fix it, put down the handle and drop .

1.2. Rotate the trimmer to lower the scraper to the bottom (clicking sound is heard), and press the zero key on the differential head to set the zero point.

2. Set the thickness

2.1. After setting to zero, turn the trimmer in the opposite direction to set the coating thickness.

3. Coating

3.1. Start up and display the company welcome interface, click anywhere on the screen to enter the experiment interface.

3.2. Click the input box behind "Set Speed", click the number to input the speed required for the test, and press the "OK" button to save.

3.3. Put the coated liquid in front of the scraper, click the "Start" button on the screen, and the scraper will complete the coating according to set speed.

4. Return to cleaning

4.1. After the coating is completed, lift the lift handle of the scraper and click "Reset".

4.2. Clean the scraper and prepare for the next coating

equipment maintenance

1. Always keep the machine clean;

2. Do not use toxic drugs, organic solvents, etc. to clean the surface of the equipment;

3. The disassembly of the machine must be carried out by professionals, using reasonable tools or equipment;

4. The frequency converter and other electronic components used in this machine have been installed internally when they leave the factory, and cannot be changed by themselves ;

5. Pay attention to moisture-proof.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Lab Film Applicator Application Case of applying water-based paints on paper [with experimental video]

- 5Experimental Application Technology of Resin Film Prepared by Spreader

- 6Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 7Several Common Experimental Spreader Methods and Their Applications

- 8Application of laboratory coater coating aluminum oxide paste on PET film

- 9Experimental test of performance of epoxy resin film coated on metal iron plate by small coater