Detailed operation steps of TQC double-slot scraper Fineness Meter

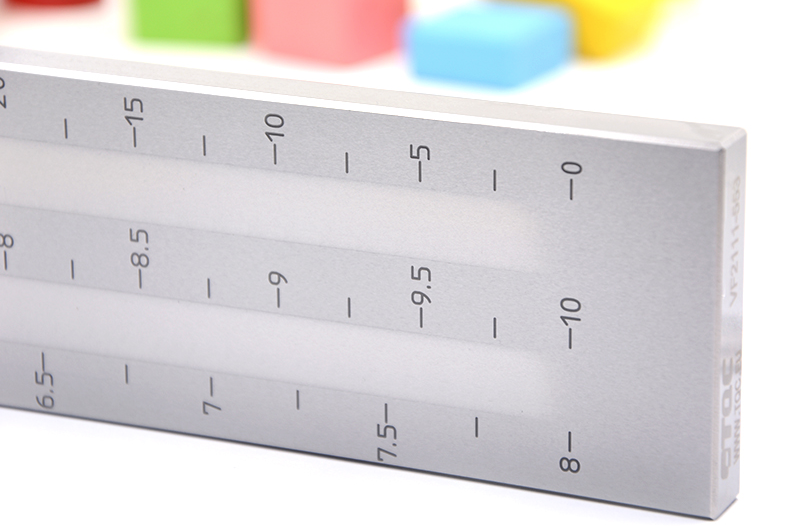

Scraper gauges are precision instruments used to determine the particle size and fineness of many materials such as paints, varnishes, pigments, fillers, chocolate, etc. Most TQC mills have dual slopes with graduated slopes of three different parameters: Micron, NS (Hegman) and PCU (Northern).

The gauge and beveled scraper are made of hardened stainless steel with an accuracy of 2 µm.

Standards compliant

ASTM D 1210, ASTM D 1316, JIS K 5600-2-5, ISO 1524, DIN EN 21524, BS 3900-C6

operation method

When using the scraper fineness gauge, be careful not to damage the surface of the gauge or the edge of the scraper. Make sure the surface of the gauge and edge of the scraper is clean of residue, grease, etc. A preliminary test is performed to determine the appropriate gauge size for the fineness of grind characteristics of the material being tested.

1. Place the manometer on a flat, level and non-slip surface with the zero mark on the scale closest to the user.

2. Put an appropriate amount of material into the deep end of each groove.

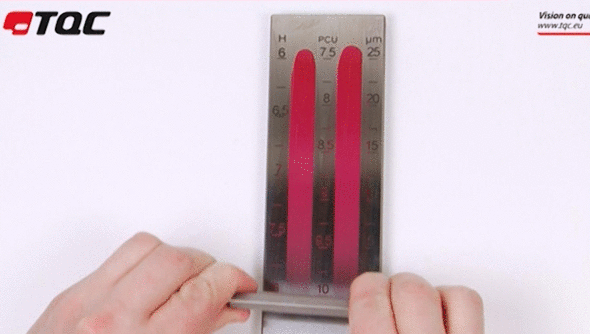

3. Place the scraper on the surface of the gauge behind the material. Hold the scraper with both hands as shown in Figure 1.

4. Pull the scraper along the length of the fineness scraper at a constant speed and apply enough downward pressure to remove excess material from the edge of the scraper. This operation takes about 1 to 2 seconds.

5. Look at the scraped material in the next 3 seconds. This avoids inaccurate testing due to material evaporation. The material should be viewed at right angles to the length of the groove and at an angle of 20° to 30° to the face of the gauge.

6. As shown in Figure 3, find a band on the 3mm wide groove that contains 5 to 10 particles of material. Read the position of the upper end of the band on the scale and record the value.

7. Clean the gauge and scraper with a suitable solvent.

8. Perform 2 more tests and calculate the average of the results. The average value is the fineness of grind of the material.

maintenance

Always clean the instrument with an appropriate solvent after use.

Never use any mechanical means such as wire brushes or sandpaper to clean the instrument. Like using aggressive cleaners, this can cause permanent damage.

When the instrument is not in use, it needs to be protected from rust. Rust may appear on the instrument only with occasional use or when handled by the user with sweaty hands.

Please be sure to dry the fineness plate and scraper after use to prevent rust, and apply a thin layer of oil to the surface of the instrument and scraper before storing.

Always store the Squeegee Gauge in the bag when not in use.

Regularly inspect gauges and scrapers for wear or damage.

Be sure to dry the instrument and scraper after use to prevent rust, and apply a thin layer of anti-corrosion oil on the surface of the instrument and scraper before storage.

- 1Coating fineness of ground - Fineness gauge

- 2Coating fineness test method and influencing factors

- 3Fineness Detection of Precious Metal Slurry in Microelectronic Technology with Fineness Meter

- 4Inks Fineness gauge principle results and usage introduction

- 5Basic Principle and Application Analysis of Coating Fineness Scraper

- 6Coating Fineness Determination and Its Importance

- 7Detection Steps of Coating Fineness and Operation Method of Ground Gauge

- 8Fineness gauge detection principle

- 9How to use Fineness of Ground Gauge to measure colorants?