Evaluation Criteria for Container Coatings

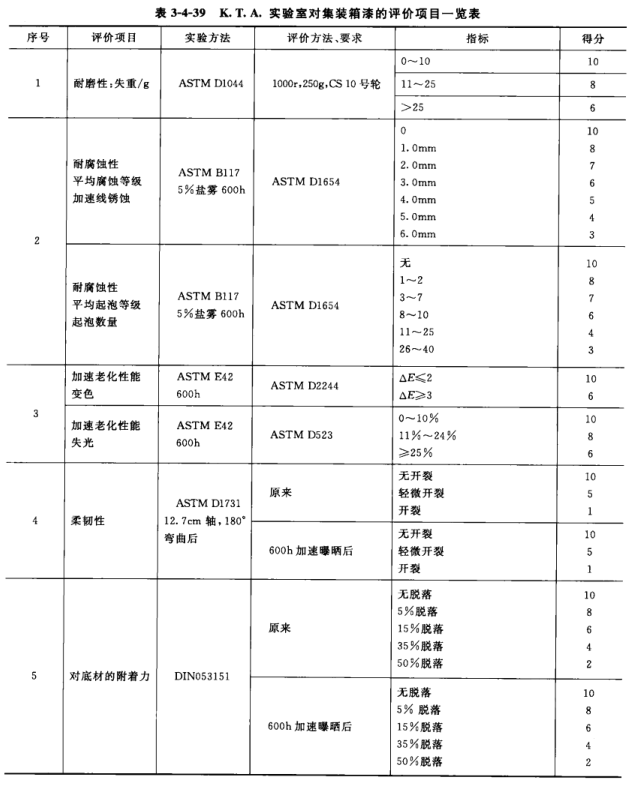

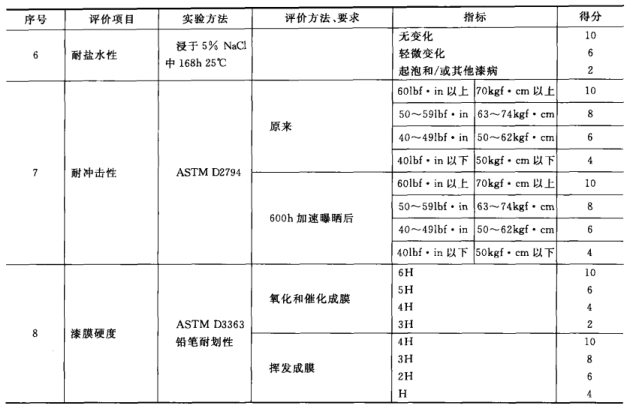

At present, there is no specific international or national standard on container coatings. The industry standard formulated by CHINA Container Industry Association is the current effective container coating standard (JH/TE01-2008). The industry generally recognizes the evaluation standard of K.TA. laboratory in the United States on container coatings. This standard requires container coatings to pass thirteen tests in eight items, with a total score of more than 120 points (out of 130 points). The testing items and indicators of KTA laboratory are shown in Table 3-4-39

Container production line and its requirements and influence on coating performance

With the advancement of container manufacturing technology and the further requirements of large-scale production, container factories with an annual output of 300,000 boxes have appeared, and the requirements for coatings have also been further improved, mainly focusing on drying performance, etc. At the same time, the stability of coatings has also been raised Due to the greatly increased production rate, it means that a large number of boxes with quality problems will be produced in the short process of debugging the paint, which is unacceptable to the box factory. Therefore, the stability of coating quality is the most basic and strict requirement for modern container coatings.

1. Configuration of coating production line in container factory

Figure 3-4-48 is a typical coating line configuration diagram of a container factory, and the functions of each station are as follows.

① Partial assembly and final assembly lines weld plates and profiles into specified container bodies.

②The optometry room passes light to check whether there is any leakage of welding bead.

③ The secondary sand blasting room re-sands the weld bead.

④OK station to clean up welding slag splash and trim the weld bead.

⑤ Zinc-rich paint pre-coating station to pre-coat the top beam, bottom beam, door frame and other parts

⑥The zinc-rich paint spraying station manually sprays zinc-rich paint on the door panel, front end and inside of the box, and automatically sprays .

⑦Intermediate paint spraying/internal paint pre-coating The intermediate paint spraying is carried out outside the box, in which the door panel and front end are sprayed , the side panels and roof are sprayed automatically, and the top beam, bottom beam, door frame and other parts in the box are sprayed on the inner surface Paint pre-coated.

⑧Intermediate paint leveling/intermediate paint leveling/internal paint spraying on the top plate of the station box, and internal paint spraying on the top plate inside the box

⑨Leveling room intermediate paint, inner paint leveling

⑩The low-temperature drying room bakes the intermediate paint outside the box to facilitate the spraying of the outer paint

①Spray inner paint on the side panels of the station box and spray inner paint on the inner panels

⑩Transverse station moves the container to the designated position for the next station operation, and at the same time, the paint inside and outside the box is leveled

③External paint/underframe paint pre-coating station The outer top beam, bottom beam, door frame and other parts of the box are pre-coated with outer paint, and the inner bottom beam underframe paint. Paint spraying, where door panels and fronts are painted manually, side panels and top panels are painted automatically

⑨The drying room makes the outer paint surface dry, so as to facilitate the operation of the next station

⑩Separate the color of the boundary room to the door frame, R corner and other parts

⑩ drying room to dry the paint inside and outside the box

⑩Forcibly cool the room by blowing cold air to reduce the temperature of the box to room temperature, so as to facilitate the operation of the next station.

⑨The repairing station inspects the box and repairs the defects. The secondary station can measure the film thickness and decorate the line for flooring, labeling, installation of door lock levers and door seal strips, installation of ventilation hoods and signs , sealant and other decorative work, as well as bottom frame paint spraying and watertight experiments, etc.

④ Check the container body for the last time at the exit of the container, and place the container in the yard.