Test principle and operation method of Pushen ZHY automatic scratch instrument

ZHY type automatic scratch Tester is carefully designed and manufactured according to the relevant regulations in CB9279-88 "Scratch Test of Paints and Varnishes" and ISO 12137-2:1997 "Determination of Scratch Resistance of Paints and Varnishes". This Tester is used to determine the scratch resistance and scratch resistance of single or composite coating systems of paints and varnishes or water-based wood paints under standard conditions. The instrument adopts a gear reducer with a large speed ratio and a large output torque to ensure a constant moving speed of the stylus under different test loads, so that the test results have high accuracy. What this instrument can do at present is the test of two kinds of substrates. One is to test the coating scratch resistance of paint and varnish water-based wood paint. The substrate is metal. Whether the paint film is scratched can be intuitively obtained through the indication of the voltmeter on the instrument. The other is to test the scratch resistance of water-based wood paint. The substrate is wood. Whether the paint film is scratched is the result of observation with the naked eye or a magnifying glass.

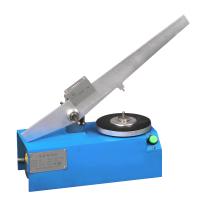

Structural principle

The automatic scratch Tester uses a constant speed motor to drive the scribing needle to slide through the rack and pinion transmission, and the scribing needle is perpendicular to the paint film. The tip of the scribe is a hardened steel hemispherical needle with a diameter of 1 mm. There is a bracket on the top, and weights from 50g to 2000g can be placed on the bracket as needed. There is an automatic balance weight used to balance the stand at the rear of the stand. The rotating shaft of the weight bracket is supported by ball bearings, which can rotate flexibly and reduce the frictional moment, so that the pressure applied to the tip of the diamond stylus has good repeatability, that is, the test results have good repeatability. The instrument is equipped with a clamping mechanism for clamping the slate. The rear part of the bracket is provided with a needle-lifting bolt for lifting the needle when the needle is reset. There is a voltmeter on the panel of the machine. When the paint film on the sample board is pierced by the needle, the voltmeter will give an indication, so that it can be determined whether the paint film is pierced, eliminating human error.

Specific operation method

1. Preparatory work before the test:

(1) Preparation of test board:

a. Material and size: Unless otherwise specified or agreed, the size of the test plate substrate should be a rectangle of 150*70mm, and meet the requirements of the tin plate, thin steel plate and hard aluminum plate specified in GB9271. If the sample to be tested requires brushing, the size of the substrate used should be slightly larger, and the brush pattern should be parallel to the short side of the board. After drying, a 150*70mm test board can be cut all the way on the short side of the test board. The base material of water-based wood paint is wood.

b. Treatment and application of test panels: Unless otherwise specified or agreed, it shall be carried out according to GB9271, and then the samples to be tested shall be applied according to the specified method.

c. Drying of test panels: Unless otherwise specified, the test panels shall be dried as specified for the product under test. Then the test panel should be dried for at least 16 hours under the conditions of temperature (23±2)℃ and relative humidity (50±5)% before testing.

(2) Ambient temperature: Unless otherwise specified, the test should be carried out at (23±2)°C and (50±5)% relative humidity.

2. Operation method:

(1) The instrument is placed on a stable and flat test bench, and the operator is facing the instrument.

(2) Take down the scribing needle, and use a magnifying glass to observe that the scribing needle should be smooth and hemispherical, without obvious wear and dirt, otherwise, replace it with a new scribing needle. The installation height of the needle and guide column can be adjusted according to the thickness of the test plate.

(3) Unscrew the fastening bolt on the sample fixture at the left end, put it under the fixed plate, with the coating of the test plate upward, and then tighten the fastening bolt.

(4) Insert the power plug into the power socket on the wall, and turn on the power switch.

(5) The following operations require three tests on each of the two test panels:

a. Pass and fail test of fixed load: put the required weight on the weight bracket. Press the "scratch" button on the instrument. If the voltmeter has an indication during the scratching process, it proves that the paint film has been scratched. A "Fail" was recorded if the coating had been scratched on one or more of the six test surfaces.

b. Minimum load test for determining scratch-through coatings: start with a small load, and then gradually increase the load in appropriate increments until the coating is scratched. Repeat the test with this load on the unmarked part of the test panel and on another new test panel. After the results are consistent, record the minimum load value.

(6) Turn the needle lifting bolt on the right side of the instrument, and remove the test plate for observation.

(7) Press the "Reset" button, the needle will return to the original position, and the next scratch can be started.

Precautions for use

1. If it is to measure the scratch resistance test of water-based wood paint, since the substrate is wood, the voltmeter has no indication. Remove the test panel after scratching to observe whether the test panel is scratched. A magnifying glass of appropriate magnification can be used as needed, but the magnification should be indicated in the test report.

2. The balance weight on the machine bracket is used to balance the self-weight of the bracket. The position of the machine has been adjusted and determined when the machine leaves the factory. Please do not loosen the screws on the balance weight easily, so as not to affect the accuracy of the test.

3. After all the tests are over, take off the weight and put it back to the original place, and cover the wooden box cover to protect the plot of the instrument.

- 1What is the principle of scratch testing?

- 2Determination of Bonding Strength of Hard Coating by Automatic Scratch meter

张平余;刘洪;王秀娥;顾则鸣;侯企贤;肖永东 - 《摩擦学学报》

- 3Modern environment HY-IV type, scratch Tester operating instructions

- 4Modern environment ZHY type, automatic Scratch meter operating instructions

- 5Discuss and analyze the failure mode of micron-scale dural soft foundation system in scratch test

杨杰; 沈耀; 蔡珣 - 《微米级硬膜软基系统在划痕试验中的破坏方式》

- 6How to comprehensively evaluate the bonding force of membrane base by scratch method?

- 7Scratch meter energy consumption measurement improvement scheme

黄林国 - 《单摆划痕仪能耗测量方法的改进》

- 8Impact scratch method for determination of bonding strength of Ni-P chemical platings

- 9Introduction of coating bonding force detection method