Specific test methods for dyne pens

Dyne pen is a surface tension test pen used to accurately test whether the surface tension of the plastic film reaches the value of the test pen. In order to know whether this plastic film is suitable for printing, lamination or aluminizing. Effectively control quality and reduce tool delays caused by unqualified materials. In fact, the Dyne pen is not limited to plastic films, but can also test the surface tension of other flat materials.

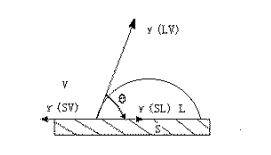

In general, thin film substrates are energy-dependent for the formation of ink droplets, coatings, and surfaces. If the energy of the surface of the substrate is lower than the surface tension of the applied test solution, bead points are formed and the drawn line shrinks (as shown in Figure 1), which is called wetting. The original surface tension of most plastic substrates is relatively small, and the original surface tension of several polymers is roughly as follows:

Table 1 Surface tension of some plastics (mN/m, 20°C)

| plastic | Surface Tension | plastic | Surface Tension |

| PTFEpolytetrafluoroethylene | 18.5 | pvc | 39 |

| PVF polyvinylidene fluoride | 28 | PMMA | 39 |

| PCTFE polychlorotrifluoroethylene | 31 | PVDC | 40 |

| PE,PP | 31 | PET | 44 |

| P.S. | 33 |

The surface energy usually used as an ink solvent is: ethanol 22 mN/m, ethyl acetate 24 mN/m, and the preparation of ink needs to add resin, binder, pigment, and additives, and the surface tension generally needs to be 38-42. Because of left and right. The value of the surface tension of the plastic is related to the molding temperature, cooling speed, additives and whether it is treated or not. Therefore, the BOPP film commonly used in color printing must be corona treated before printing so that the surface tension cannot be less than the surface tension of the ink, so as to achieve wetting. ,As shown below.

Figure 1. Schematic diagram of film-ink wetting tension

In the figure θ is the wetting angle. Obviously, when θ>90°, it is not wet due to the small wetting tension; when θ<90°, it is wet; and when θ=0°, it can be completely wetted. It can be seen that the surface tension of the film must be at least 38 dynes, so that the wetting angle between it and the ink is less than 90°, so that wetting can be achieved, so that the printing effect is better.

If the surface tension of the film is further increased, or if the surface tension of the ink is reduced, will the printing effect be better? Can the so-called wetting angle be zero? To be precise, regardless of cost and physical feasibility, theoretically, such a little bit of ink will cover the entire film, and various colors will mix together, and the pattern will no longer be visible. up.

For most films, the surface tension of the film before printing requires a dyne pen between 36-40 dyne/cm.

Nylon requires about 52 dyne/cm, and PET requires about 48 dyne/cm to be equipped with a dyne pen.

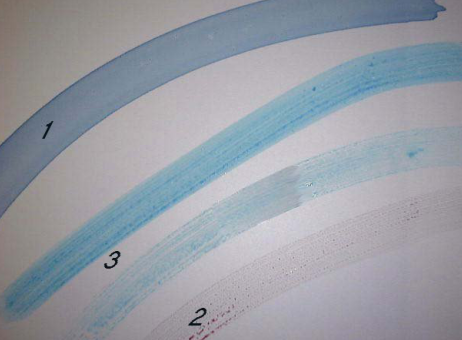

How to use: The dyne pen is perpendicular to the plane of the film, with appropriate pressure, gently draw a line on the surface of the film (see the picture below). Generally, three adjacent dyne pens are required.

Dyne pens with different dyne numbers for film line drawing

analysis results

1. If the drawn lines are evenly distributed without any beads, it means that the surface tension of the film is higher than the index marked on the Dyne pen, and it can be printed in this case.

2. If the drawn line shrinks slowly, it means that the surface tension of the film is slightly lower than the index marked on the Dyne pen. In this case, the printing effect is not good.

3. If the drawn line shrinks immediately and forms bead points, it means that the surface tension of the film is much lower than the index marked by the Dyne pen. This case cannot be printed.

Both methods are simple, fast and effective, and the test result can be known quickly only by scratching a mark (length 10~20mm) on the surface of the substrate. This is specially designed for testing on the production line and is carried out by factory trained operators. When testing, you should choose an intermediate value as the starting point. For example, when testing with a dyne pen at 38mN/m, if the test pen wets the surface of the substrate within 2 seconds, the surface tension of the substrate is larger or just right than the selected value. Then it is necessary to choose a test pen with a larger value for the second test, and so on, until the test result shrinks into a water drop shape (a small water ball shape with a relatively uniform distribution in the scratch) within 2 seconds, then this test The previous value is regarded as the surface value of the substrate.

If the first test shrinks into water droplets in the scratches of the substrate, replace the test pen with a smaller value for the second test until the surface of the substrate is wet (the scratches will still remain after a few seconds) No change), the value of this test is regarded as the surface value of the substrate.

This method can accurately test the surface tension/surface wetness of the substrate and determine whether the surface factors of the substrate meet the requirements before work so as to adjust the ink/coating/viscosity to the work.

The surface tension/surface wetness test pen is a very clear standard for accurately determining the bonding status of printing ink and other materials on the Polyolefin surface, but there are other factors that affect the viscosity, such as static electricity and many additives, etc. However, these factors are in It doesn't often show up when testing, or even when the test results are good but the actual requirements are not met. This requires discussing these technical issues with raw material suppliers. Generally speaking, the above situation will not happen to them, and the viscosity requirement can be met if the surface value is 38~41mN/m, and the surface tension is below 36mN/m. Sometimes it will cause poor printing adhesion.

The surface tension/surface wetness test pen can also accurately determine the oil content on the surface of metal parts and other materials.

Pull out the cap of the surface tension/surface wetness test pen forcefully when using it, and inlay the cap at the end of the pen body to avoid loss. Cover the pen cap at any time after use to prevent the vapor and liquid in the pen body from volatilizing from the pen tip, which will affect the accuracy of future tests.

When capping the pen cap, you should hear a crisp "snap" sound, which means the cap is in place.

The surface tension/surface wetness test pen is not easy to store at a place above 25°C, let alone near a place with an open flame.

The Surface Tension/Surface Wetness Test Pen should be kept out of the reach of small children.

-

-

Fengzhiyue 54 Dyne pen$ 84.00

-

-

Fengzhiyue 48 Dyne pen$ 84.00

-

-

-

Fengzhiyue 56 Dyne pen$ 84.00

-

-

Fengzhiyue 50 Dyne pen$ 84.00

- 1Application of Dyne pen in surface tension measurement

- 2Dyne pen in film printing

- 3Dyne pen test method

- 4How to Use a Dyne Pen to Determine Surface Energy

- 5How to Ensure the Accuracy of the Dyne Pen Test

- 6Dyne Pen Controls Surface Tension of Printed Coatings

- 7Four simple steps to use the dyne pen correctly

- 8Dyne pens and test fluid -- how do they work?

- 9What is dyne level?