Paper Properties: Moisture and Stiffness

paper moisture

Paper moisture refers to the water content in paper, expressed as a percentage. The moisture content of paper plays a decisive role in printing, post-press processing, product storage and product use.

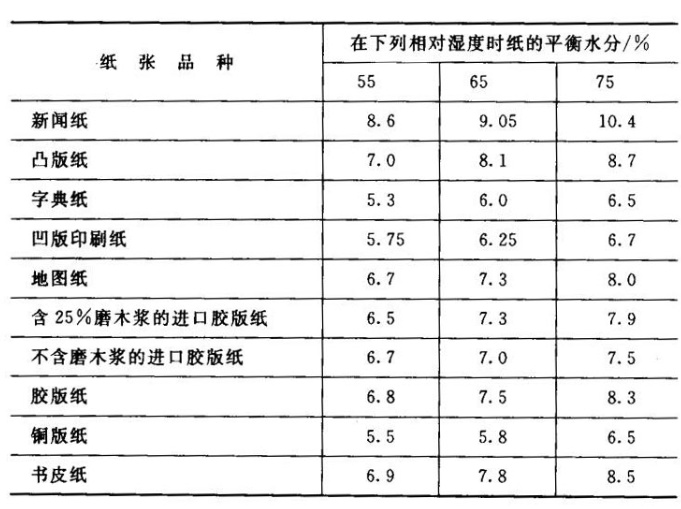

Paper moisture directly affects the flexibility of paper; paper moisture slows down the drying of ink, reduces the tensile strength and surface strength of paper; paper moisture is small, paper is brittle, prone to static electricity, resulting in double and empty printing. Table 1 shows the equilibrium moisture of commonly used printing paper.

paper stiffness

Paper stiffness is the bending moment when the cardboard is bent at a certain angle under certain conditions. According to the national standard GB2679.3-8 "Determination of Paper Stiffness", take samples: length (70 ± 1) mm, width (38 ± 0.1) mm, no less than 5 samples in the vertical and horizontal directions. The bending angle of the sample on the instrument is 15°.

The paper stiffness index is very important to the post-press processing technology. When the paper is conveyed on the non-gripper channel type coater, the paper with poor stiffness is easily caught under the pressure roller. Sometimes it sticks back to the coating roller, and the rubber coating roller is severely squeezed to make it lose its elasticity and be scrapped. In hot stamping and die-cutting processes, poor paper stiffness will bring difficulties to continuous paper and affect processing efficiency. Cardboard with good stiffness is generally expensive, because the quality of paper-making fibers is a key factor for cardboard stiffness.