Paper Properties: Smoothness (Roughness)

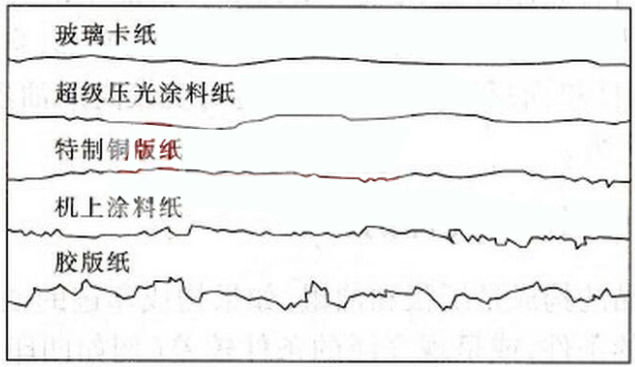

Paper smoothness (roughness) is a technical indicator for evaluating the degree of unevenness on the surface of paper and cardboard. The smoothness of paper is measured with a surface roughness meter, and there are several measurement methods.

The mechanical method is to use a needle to move on the surface of the paper, and the needle moves up and down with the unevenness of the paper surface;

The optical method is to measure the degree of diffuse reflection of light. Methods for measuring paper smoothness are constantly improving.

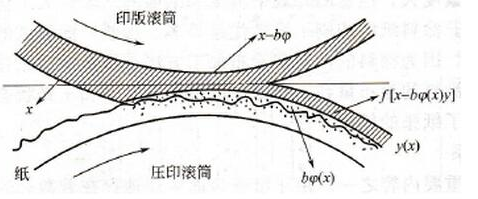

The smoothness of paper has a certain influence on printing. When printing, the paper is in contact with the printing plate or blanket. If the paper is smooth, it will be in close contact with the printing plate or blanket, the ink will transfer evenly, and the printed pictures and texts will be clear.

Papers with different smoothness are suitable for the printing of different printed matters. For example, letter line printing has low requirements on smoothness, so letterpress paper or offset paper is generally used; color picture printing should use coated paper. Different printing processes have different requirements for paper smoothness. Elastic printing plates such as offset, flexographic, resin, and rubber plates have lower requirements for smoothness, while high-hardness stereotypes and copper plates have higher requirements for paper smoothness.

When printing on paper with low smoothness, the shortcoming of poor ink transfer can be overcome by increasing the printing pressure appropriately.

- 1Influence of surface roughness of parts

- 2High-precision roughness instrument measures the surface roughness of plastic materials Case sharing [Video demonstration]

- 3How to measure concrete surface profile (roughness) quantitatively

Defelsko

- 4Evaluation of steel surface roughness

- 5The relationship between abrasive and surface roughness

- 6Roughness and Surface Roughness

- 7Which industries need to use surface roughness meters?

- 8Surface roughness measurement

- 9What are the application fields of surface roughness meter?

-

-

KAIRDA NDT151P Roughness Gauge$ 810.00

-

-

-

-