Influencing factors of paint gloss and film gloss

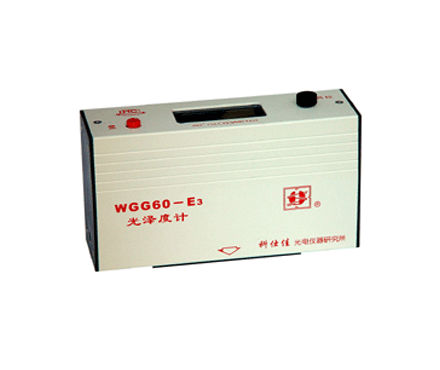

Determination of gloss and luster When light is projected onto the surface of an object, light will be reflected. The ability of the surface of an object to reflect light is called gloss. The gloss of the surface of different objects is different, and the measure of the ability of the surface of the object to reflect light is called gloss. Gloss is expressed as a percentage. The higher the glossiness of an object's surface, the stronger its ability to reflect light and the higher its brightness. The size of the gloss is measured by a photoelectric gloss meter. According to the size of the gloss, the paint can be divided into several types such as glossy, matte, and dull.

Classification of coating gloss (take 60°reflective gloss (that is, the light incident angle is 60°) as an example):

Matt paint: Gloss < 10%;

Matt paint: gloss 15-60%;

Gloss paint: gloss > 60%.

Factors Affecting Gloss

1) Roughness of the coating surface

The surface gloss of an object is closely related to the roughness of the object surface. When light hits the surface of an object, part of it will be absorbed by the object, part will be reflected and scattered, and part will be refracted. The smaller the roughness of the surface of the object, the more light is reflected and the higher the gloss. On the contrary, if the surface of the object is uneven, the scattered light will increase, resulting in a decrease in gloss.

The roughness (h) of the surface of a bright object that can be felt by human vision can be calculated according to the formula: h = λ/cosα by using the knowledge of microsurface theory, where the wavelength of incident light is the wavelength of human light; α is the angle of incidence. For example, when the human shooting angle is 60°, h=1.1μm can be calculated. When the surface roughness h of the object is greater than 1.1μm, it will appear uneven and the gloss will decrease.

2) Film formation process of coating film

After the paint is painted on the surface of the object, it is cured to form a film by the volatilization of the solvent (for solvent-based paints). There is no need to repeat the importance of the surface roughness and gloss of the coating film during the formation process of the coating film. In the wet film stage, the volatilization rate of the solvent is controlled by the diffusion of the solvent on the surface of the coating film. When the volatilization rate of the components of the solvent is not much different, it is possible to obtain a high-gloss surface; conversely, when the components of the solvent are wet When the volatilization rate of the film stage is different, it will make the polymer molecules tend to form curls, or even precipitate, and become particles or agglomerates of different sizes, and the surface of the coating film will appear uneven. In the dry film stage, the volatilization rate of the solvent is mainly controlled by the diffusion of the solvent in the whole coating, and it will also affect the roughness of the coating film surface. In addition, during the formation of the coating film, with the volatilization of the solvent, the coating film will become thinner and shrink, and some suspended heavy particles in the coating will rearrange on the surface of the coating film, causing the surface of the coating film to be uneven.

3) Particle size and distribution of pigments and fines

The particle size and particle size distribution of the pigment (filler) in the paint are one of the important factors affecting the gloss of the paint film. It was found in the research that when the diameter of the pigment particles is less than 0.3 μm, a high-gloss coating film can be obtained. The reason is: after the pigment particles dispersed in the paint are made into a coating film of a certain thickness and dried, only the topmost pigment particles protrude locally, and the surface roughness of the coating film caused by the pigment ions with a particle diameter of less than 0.3 μm It will not exceed 0.1 μm. When the average particle diameter of the pigment is between 3 and 5 μm, a coating film with better matting effect can be obtained.

In addition to the above three factors that can affect the gloss of the coating surface, factors such as the volume concentration of the pigment (PVC), the dispersibility of the pigment, the surface structure and surface reflection characteristics of the coating will also affect the gloss of the coating surface. Among them, as the PVC of the pigment increases, the glossiness of the coating film surface first decreases, and a minimum value appears at the limit volume concentration (CPVC) of the pigment, and then with the increase of PVC, the glossiness also increases. When the type and amount of pigment are determined, the better the dispersion, the higher the gloss of the coating surface.

- 1Principle and Application of Glossiness Tester

- 2Working Principle and Application of Metal Gloss Meter

- 3Basic principle and application analysis of insulating paint gloss Detector

- 4Working principle and application analysis of film Glossmeter

- 5Principle and application analysis of microporous gloss meter

- 6 FZ/T 01097 Analysis of fabric gloss test method

- 7Evaluation and Application of Optical Properties of Powder coatings

- 8Coating coatings - Determination of surface gloss and Gloss meter

- 9The Importance and Method of Gloss Measurement of Paint Film