Application of gloss meter in detecting toy surface quality

As those born in the 90s, we always sigh that children are so happy now, with so many toys. Toys accompany children's growth, and the quality of toys has a certain impact on children's health to some extent. In order to ensure the quality of toy products, strict testing is required before leaving the factory. Gloss is an important indicator of toy quality testing. This article will bring you the method of gloss testing toy quality.

What are the requirements for the glossiness of toys?

Gloss is an appearance characteristic of a toy display, and it and the appearance color of the product can give users a visual first impression. Toy gloss mainly depends on the refractive index of the surface and the smoothness of the surface. When the refractive index of the packaging material is high and the surface is smooth, the specular reflection of the light meter is dominant, and the gloss is high; otherwise, the diffuse reflection is dominant, and the gloss is poor. The composition and manufacturing process of packaging materials are the main factors affecting the surface gloss.

Different toy products have different requirements for appearance gloss. At present, there is no unified glossiness standard in CHINA. However, in order to ensure the appearance of the product, it is necessary to control the gloss within a certain range. The difference in the material used in the toy and the treatment process will lead to a great difference in the gloss of its appearance. If you want to evaluate the gloss of the product, you can use a gloss meter to measure it.

Gloss meter to identify the gloss quality of toys:

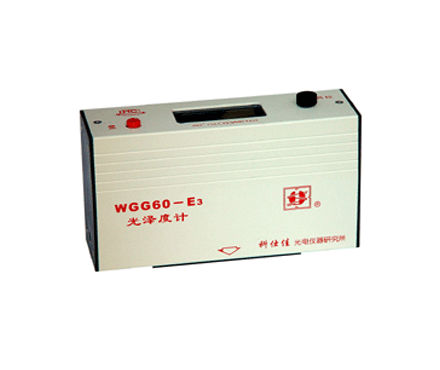

Glossiness is the property of directional selective reflection on the surface of an object, which determines the degree of strong reflected light or mirror image of the object that can be seen on the surface of the object. Generally, the glossiness of the material is expressed by the glossiness of the specular surface. The so-called specular gloss refers to the ratio of the specular reflectance of the sample to the specular reflectance of the reference surface under the same conditions at a specified incident angle, expressed in percentage, and the percentage sign is generally omitted, expressed in gloss units. A gloss meter is generally composed of two parts: a gloss detection head and a reading decoration. Contains an incandescent light source, a condenser lens, and a projector or source lens. These devices generate an incident beam of light directly onto the sample, and a sensitive photoDetector collects the reflected light and generates an electrical signal, which is amplified and excites an analog or digital display meter to display the gloss value .

When using a gloss meter, place it on a black glass reference standard plate, turn on the instrument switch, adjust the control knob, so that the gloss meter knows the corresponding value of the reference, then use the working standard version to check the linearity of the instrument, and then put the sensor on On the surface of the sample, the gloss value can be read directly from the display.

In the process of toy production, the glossiness of different batches of samples is tested by a gloss meter, and compared with the product glossiness standard specified by the company or the industry standard, to analyze whether the glossiness of the toy meets the requirements, so as to control the appearance quality of toy products .

- 1Principle and Application of Glossiness Tester

- 2Working Principle and Application of Metal Gloss Meter

- 3Basic principle and application analysis of insulating paint gloss Detector

- 4Working principle and application analysis of film Glossmeter

- 5Principle and application analysis of microporous gloss meter

- 6 FZ/T 01097 Analysis of fabric gloss test method

- 7Evaluation and Application of Optical Properties of Powder coatings

- 8Coating coatings - Determination of surface gloss and Gloss meter

- 9The Importance and Method of Gloss Measurement of Paint Film