Corrugated cardboard indentation strength detection technology

Introduction

With the continuous improvement of the degree of automation, the production of cartons must meet the needs of automated packaging. If the production process is frequently interrupted, the production efficiency will be greatly reduced and the loss will be increased. The consequence is that there will be no opportunities for future test machines. It also means that you can no longer get the order. In order to meet the carton needs of automated packaging production users, in addition to the determined size must always be consistent, the crimping of the carton is also a very important part. The automatic packaging line is completed by many mechanical devices and manipulators. If it is not in place or the creasing depth is not enough, the cartons cannot be lined up or the line is not in place, which will cause the failure of the packaging action, and serious blockage will cause the line to stop. Especially the crimping line at the carton flap, if the indentation force is insufficient, it is shallow and cannot be formed, especially the crimping line of the flap is easy to jam the machine, and if the automatic packing box is sealed by dispensing, the crimping line is not in place, and the rebound force is large Easy to open the glue, the box cover pops open.

The method for evaluating the indentation force of corrugated boxes is the indentation rate. The indentation rate refers to the ratio of the indentation force of the indented sample to the indentation force of the non-indented sample, expressed in percentage (%). At present, there is no national standard in CHINA, but there is TAPPI T829 standard abroad.

According to the needs of foreign customers and the requirements of the TAPPI T829 standard, referring to the introduction of this kind of instrument abroad, after several months of continuous struggle, the research and development department of Pinxiang Technology developed this indentation rate Tester on the basis of the Tensile Strength Tester. Instrument PN-SQT500 Indentation rate Tester. The instrument is designed for mechatronics, and adopts a vertical structure mechanically. The lower end of the measuring device is a U-shaped bracket, and the upper end is a measuring bar. The operation is simple and convenient. It adopts the current relatively fashionable touch screen display mode, one-key measurement, real-time display of pressure value, deformation and test time. After the test, the system automatically calculates the average value of samples with indentation and the average value of samples without indentation. value and indentation rate. The specific test process is as follows:

Detection steps

1. Test equipment

PN-SQT500 Indentation Strength Tester This instrument is an electromechanical integration equipment, mechanically adopts a force structure, the lower end of the measuring device is a U-shaped bracket, the upper end is a measuring bead, and the sample is placed in the middle; the hardware and software adopt high-speed ARM Processor and modular circuit; the display adopts a relatively fashionable touch screen for display control, only a few parameters need to be input: test speed, distance and sample, one-key test, the software displays the pressure value, deformation and test time in real time, and the test End The system automatically calculates the average value of samples with indentation, the average value of samples without indentation and the indentation rate. It can be connected to computer software to facilitate the export of test data to EXCEL, which is convenient for data storage, analysis and processing.

2 Sample preparation Sampling

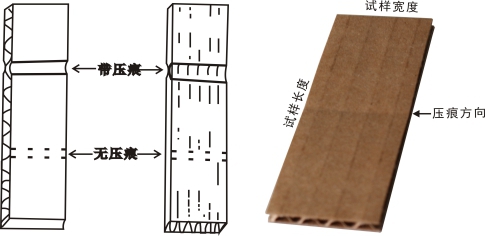

shall be carried out according to the requirements of GB/T 450, temperature and humidity treatment shall be carried out according to the requirements of GB/T 10739, and tests shall be carried out under this atmospheric condition. Regardless of the sample with or without indentation, the width of the sample should be at least 25.4mm (indentation length direction, generally 25.4mm-100mm), and the length should be long enough, generally not exceeding 100mm (generally 50mm-100mm), otherwise Will withstand the dust cover, as shown in Figure 1.

Figure 1 Schematic diagram and physical picture of indentation direction parallel or perpendicular to corrugated direction

3. Test steps

3.1 Prepare the instrument

Place the instrument on a horizontal workbench, plug in the power cord, and turn on the power.

3.2 Select working mode

The instrument has two test modes: 12.7mm or 90°. The 12.7mm mode is to test the pressure and displacement of the bead when the test bead touches the sample, press down to 12.7mm stroke; the 90° mode means that the sample is bent to 90° by the test bead, and the pressure and displacement of the bead are tested.

3.3 Parameter setting

Parameter setting mainly includes test speed, distance setting (distance from test bead to U-shaped support) and the number of samples. The test speed standard TAPPI T829 stipulates 48mm/min; according to the thickness of the sample, it is generally slightly larger than the thickness of the sample, and the spacing setting only needs to be set once, and the same sample is directly placed on it for the second test; The number is particular. If there are 10 samples with indentation and 10 samples without indentation, then the number of samples is set to 20.

Note: After the test, press the "Statistics" button to automatically obtain the indentation rate. The system defaults that the first 10 samples are samples with indentations, and the last 10 samples are samples without indentations, so special attention should be paid when placing samples .

3.4

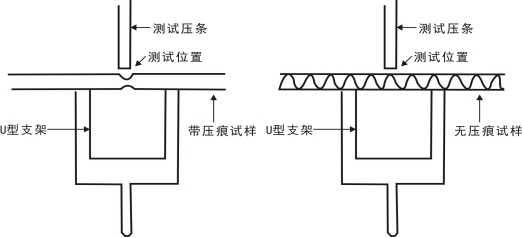

When placing the sample for testing, place the sample with indentation first. There are two types of samples with indentation: one is that the MD indentation direction is perpendicular to the indentation; the other is that the CD indentation direction is parallel to the indentation ,As shown in Figure 1. When placing the sample, align the indentation line of the sample to the middle of the U-shaped support, so that the indentation line, the test bead and the center line of the U-shaped support are on the same straight line, as shown in the schematic diagram and physical diagram in Figure 2.

Figure 2 Schematic diagram of sample placement

Note: If the test CD direction is parallel to the corrugated non-indented sample, the test bead should be aligned with the corrugated peak.

3.5 Reset

Press the "Reset" button to initialize the force value.

3.6 Test

Press the "Test" button to start the test program, the screen will display the force value and time in real time, when the test is over, the screen will display the test result, and the test bead will reset. Remove the crushed sample, place the next sample, press the "Test" button to continue testing until a group of samples is tested.

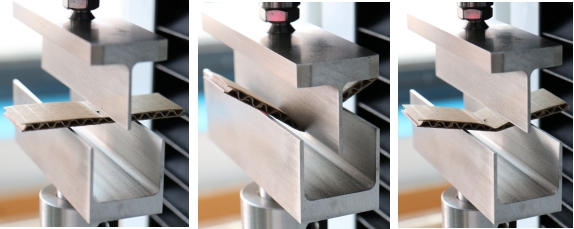

The state of the sample during the test is shown in Figure 3:

Figure 3 Test process

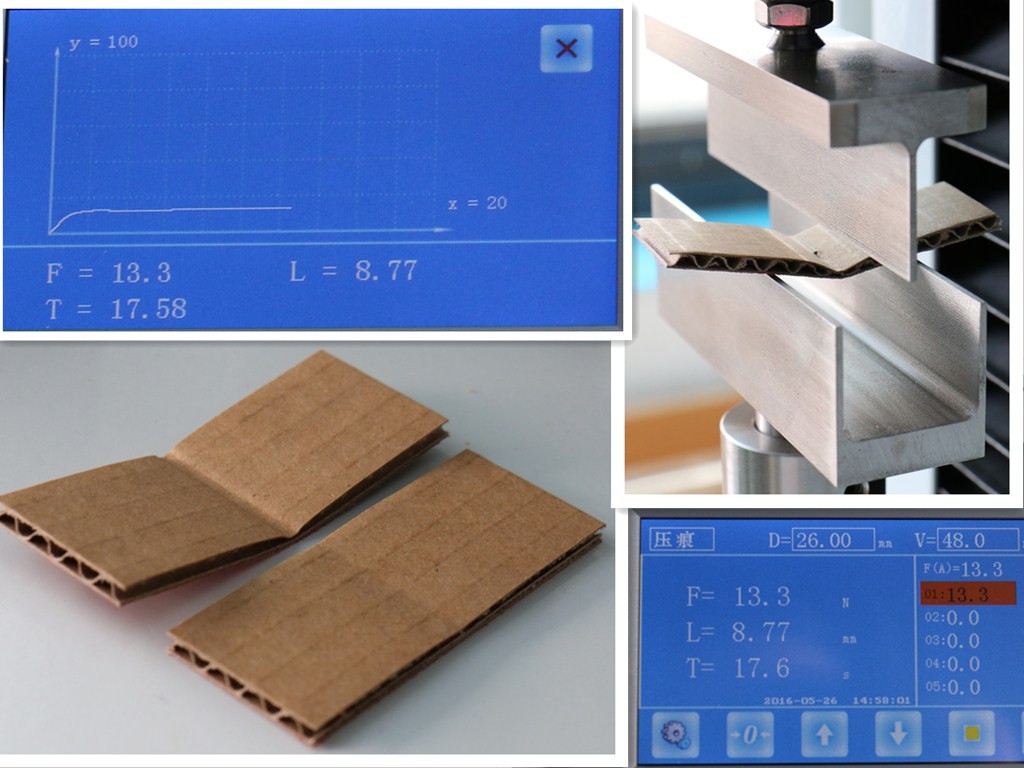

The test results are displayed on the screen as shown in Figure 4:

Figure 4 end of test

If the indentation rate is within the specified range, the indentation of the corrugated cardboard is qualified; otherwise, it is unqualified.

For the indentation parallel to the corrugated direction, when the indentation line falls on the corrugated peak or flute valley of the corrugated core paper, the indentation quality is generally better, and the forming size of the carton can be easily guaranteed. However, if the indentation line falls between the corrugated peak and the corrugated valley, that is, at the half-waist, the indentation quality will be difficult to guarantee, and the forming size of the carton will often deviate.

3.7 Calculation of the results

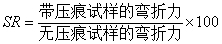

The indentation rate SR of the indented cardboard is expressed in percentage (%) and calculated according to formula 1

...................................(Formula 1)

If the indentation rate is within the specified range , the indentation of the corrugated cardboard is qualified; otherwise, it is unqualified.

3.8 Data query and printing

After a batch of sample tests are completed, the test data can be queried, counted, and test reports can be printed. Press the "Statistics" key to display the statistical results on the screen, then press the "Test" key to print the statistical report. You can also print a single test report, the method is to select the data to be printed and then directly press the "print" button to print.

conclusion

This issue introduces the detection method of indentation strength of corrugated board, which is mainly applicable to single corrugated board and double corrugated board, also suitable for triple corrugated board, but the reliability is poor. The indentation strength of corrugated boxes is important to assess the quality of corrugated boards, such as for the effective assembly and sealing of corrugated boxes. For the indentation parallel to the corrugated direction, when the indentation line falls on the corrugated peak or flute valley of the corrugated core paper, the indentation quality is generally better, and the forming size of the carton can be easily guaranteed. However, if the indentation line falls between the corrugated peak and the corrugated valley, that is, at the half-waist, the indentation quality will be difficult to guarantee, and the forming size of the carton will often deviate.