How does the modern environmental JTX-V scrubbing Tester test the scrubbing resistance of architectural coatings?

JTX-V Scrub Tester (Multi-purpose Scrub Resistance, Stain Resistance, and Wet Scrub Resistance) is based on GB/T9266 "Determination of Scrub Resistance of Architectural Coatings" and GB/T 9755 "Synthetic Resin Emulsion Exterior Wall Coatings" Appendix C Requirements for Scrub Test, GB/T 9780 "Test Method for Stain Resistance of Architectural Coatings" Standard Requirements for Stain Resistance Test, GB/T 31410 "Scrub Resistance and Cleanability of Paint and Varnish Coatings" It is designed and manufactured according to the requirements of "Evaluation of Wet Scrub Resistance" and is used to evaluate the scrub resistance, stain resistance and wet scrub resistance of coatings. overlay, wood density, etc.) properties.

The device performs a scrubbing test on the paint painted on the standard test plate, and the scrubbing times can be controlled and read out by the touch screen. The scrub resistance of the coating is evaluated according to the number of times of scrubbing resistance, and the stain resistance and wet scrub resistance of the coating are evaluated according to the comparison before and after scrubbing.

Scrub resistance test

1. Soak the brush in 20°C water for 30 minutes in advance, with a depth of 12mm, then take out the brush and press it dry, then soak it in 0.5% soap solution for 10 minutes.

2. Put the test plate in the working tray, and then clamp the test plate with the quick clamps on both sides, and the test plate must not have any serial movement during work.

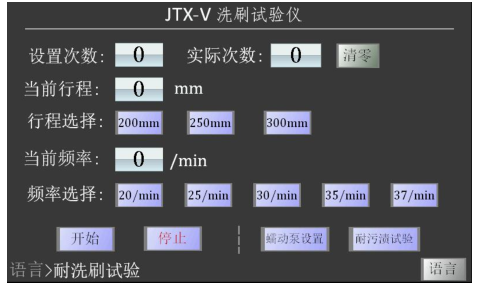

3. Put the brush into the brush holder, tighten the fixing bolts to fix the brush from loosening, and then put it into the beam brush holder to confirm that the brush moves freely.

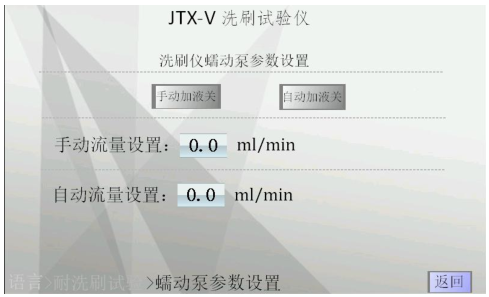

4. Put the water inlet pipe of the peristaltic pump into the scrubbing medium container.

5. Turn on the power and select the language.

6. The default interface is the washable interface, set the number of tests, select the test schedule and test frequency.

7. Turn on the automatic liquid filling switch during the scrubbing process, and the peristaltic pump will automatically drip into the scrubbing medium. Moisturize first

Click the manual mode, and after the test plate is wet, close the manual mode.

8. Observe whether there is any wear and tear at the middle 10 cm of the test plate. If you want to stop halfway (not reaching the preset value), press the stop switch to stop washing. If you want to continue washing, just press the start switch.

9. When the test piece is not exposed to the bottom and the actual count value has reached the preset value and the machine is shut down, if you want to continue the test, press the clear button

The counter display of the zero button returns to zero, otherwise it cannot be started, and then press the start switch, the counter starts counting again, and the number of washings is accumulated.

10. If it is used to test the product, just set the preset value to the qualified value, start the machine, and stop automatically when the predetermined value is reached, and check whether the test plate is exposed to judge whether the product is qualified.

Stain resistance test:

1. Put the test plate in the working tray, and then clamp the test plate with the quick clamps on both sides, and the test plate must not have any serial movement during work.

2. Fix the gauze on the scrubbing jig, then put it into the beam of the brush holder, and put a suitable weight on it.

3. The following is the same as the previous "washing resistance test" steps.

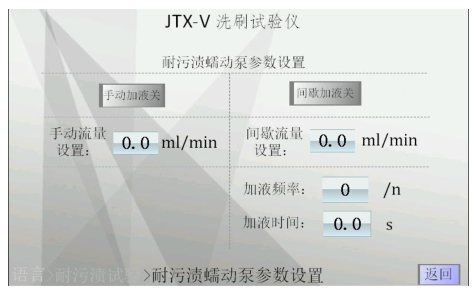

4. There is no need to add liquid manually during the stain resistance test. Turn on the intermittent liquid addition switch to set the frequency and time of liquid addition.

Precautions

1. After each test, the liquid storage tank, glass plate, brush and instrument working parts should be cleaned, and the panel and instrument body should be wiped dry with a dry cloth to prevent corrosion.

2. The production of the test plate should meet the requirements of national standards.