Preparation of Nano Sealing Primer

1. Formula

(1) 15-70% by weight, dispersed phase particle size less than 100nm, water-based dry oil modified

(meth)acrylic polyester emulsion.

(2) 1 to 30% pigment by weight.

(3) 5-30% filler by weight.

(4) 1-6% drier by weight.

(5) 0.3-3.0% thickener by weight.

(6) 0.3-3.0% by weight of dispersant.

(7) 0.5-5.0% by weight of other additives.

(8) 5-25% demineralized water by weight.

Instruments: Shanghai Modern Environmental Engineering Technology Co., Ltd. GFJ-04 high-speed dispersing machine, Shanghai Modern Environmental Engineering Technology Co., Ltd. KSM-2 open sand mill, Tianjin Jingke Material Experimental Machine Factory QCJ type coating film adhesion Tester, etc.

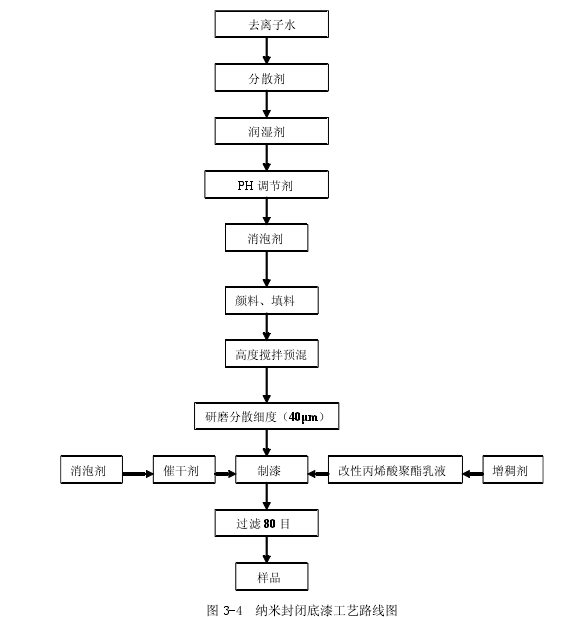

2. Process route

(1) Add the formulated amount and accurately measured demineralized water, dispersant, wetting agent, defoamer, and pH regulator into a pulping container , and stir with a high-speed disperser for 5 to 10 minutes at a speed of 300 ~500rpm.

(2) Add the specified amount of pigments and fillers, stir for 5-10 minutes, and the speed is 700-1000rpm.

(3) Use grinding equipment such as a sand mill to grind to a fineness of less than 40 µm.

(4) Add the formulated amount of color paste into the paint mixing container, add a water-dispersed dry oil-modified (meth)acrylic polyester emulsion with a particle size of the dispersed phase less than 100nm , and stir for 10-20 minutes at a speed of 500 ~700rpm.

(5) Add the drier evenly, and stir evenly after adding.

(6) Add the thickener evenly, and stir for 5-10 minutes after adding, at a speed of 500-700rpm. Filter through a 80-mesh sieve to obtain the finished product.

3. Performance indicators of nano-blocking primer

Prepare asbestos cement slabs, the size is 150mm × 70mm × 5mm , the surface treatment is according to GB9271 , and the preparation is according to GB9125

conduct. Leave it in the natural environment for 7 days after painting.

( 1 ) Alkali resistance GB9265-88

Alkali solution (saturated calcium hydroxide) preparation: under the condition of 23 ℃ ± 2 ℃, add 0.12g to 100ml of distilled water to prepare an alkali solution and stir thoroughly. The pH value of the solution should reach 12-13 .

Take 3 samples during the experiment, and seal the edges and back of the test board with a mixture of rosin and paraffin (mass ratio 1:1 ) . Then immerse 2/3 of the test plate area into the alkaline solution and observe until the surface of the test plate appears blistering, pulverization, peeling or even revealing the bottom. "Synthetic Resin Emulsion Exterior Wall Coatings" ( GB9755-2001 ) requires first-class products to have no abnormality after 48 hours of alkali resistance .

( 2 ) Low temperature storage stability

将试样装入约1L的塑料或玻璃容器(高约130mm,直径约112mm,壁厚0.23mm~0.27mm)内,大致装满,密封,放入-5℃±2℃的低温容器中,18h后倒出容器,在GB/T9278条件下放置6h。如此反复三次,打开容器,充分搅拌后应无硬块、凝聚及分离现象。

(3)对比率

按GB/T9270规定。

(4)耐水性

按GB1733-93方法测定。实验时取3块样板,以松香和石蜡混合物(质量比1:1)将试板四周边缘和背面封闭。然后将试板面积的2/3浸入碱溶液,进行观察,直至试板表面出现起泡、粉化、剥落甚至露底为止。《合成树脂乳液外墙涂料》(GB9755-2001)要求一等品耐水性96h后,无异常。

( 5 ) Adhesion GB1720-79

Method, measured by Shanghai Modern Environmental Engineering Technology Co., Ltd. coating film adhesion Tester (circle).

It can be seen from Table 3-4 that since the film-forming substance of the coating is nano-scale, the performance of the nano-blocking primer exceeds the national standard and is relatively excellent.

- 1A Brief Discussion on the Difference between Disperser and Stirrer

- 2Briefly describe the difference between High Speed Disperser and Homogenizer

- 3Several Common Coating Dispersers

- 4Inspection Contents of Chemical Plant Disperser

- 5The difference between Disperser ordinary and explosion-proof type

- 6Disperser stirring speed formula

- 7What's wrong with Disperser stirring?

- 8Main Structure of Vacuum Defoaming Disperser

- 9What oil is used in Latex paint Disperser?