Application of Halogen Moisture Meter in Quality Control of Grain and Flour

Moisture content refers to the weight percentage of the product caused by water, which is an important indicator of quality control. Gravimetric moisture analyzers are used in a wide variety of industries to confirm moisture content in compliance with regulations governing specific industries.

Agricultural products such as grains and flours derived from grains exemplify the applications of moisture analyzers. For example, the University of Minnesota Extension reports that wheat and barley kernels need to have a moisture content between 13% and 14% for safe storage. In wet weather, this can be expensive and time-consuming to achieve.

Another goal applies when wheat is milled into flour. A study by the Institute of Food Science and Technology, Pakistan Agricultural University has shown that the moisture content of flour is very important for its shelf life. Reducing the moisture content of flour increases its storage stability. The study concluded that flour with a moisture content between 9% and 10% is suitable for extended shelf life.

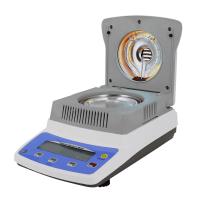

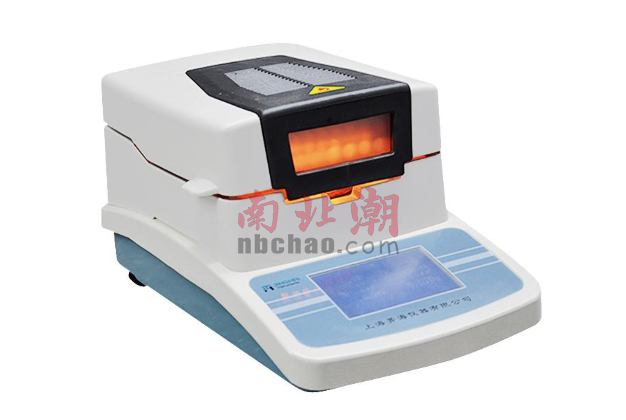

A benchtop or benchtop moisture analyzer, such as Tovatech's IL series, is an excellent choice for small sample verification of grain and flour moisture content. They act as miniature halogen-heated "vessels" placed on microprocessor-controlled analytical balances. Load the product to be measured (in this case grain or flour) onto the sample, taking care to distribute the sample evenly over the surface of the plate. Program the target moisture level or drying time into the precision scale according to the included instructions, then turn on the unit.

The halogen lamp quickly and evenly distributes heat throughout the sample, driving out moisture until the weight of the sample becomes constant (i.e. no more water is removed) or the preset drying time is reached, or the time to loss per unit weight is below the target value. The moisture analyzer then calculates and displays the moisture content of the sample. To comply with GLP record keeping requirements, the moisture analyzer can be connected to a PC and statistical printer via the RS 232 interface.

Grains and flour are just two of many food groups where the importance of the correct moisture content cannot be overstated. When moisture levels are too high, food processing efficiency is compromised, spoilage is possible, and customers pay for the excess weight due to excess moisture. Processing efficiency also suffers when food is too dry. A moisture analyzer is a wise investment to regularly check the moisture content of food in accordance with your company's operating manual.

- 1Halogen Moisture Meter comprehensive analysis: types, application scenarios and scientific selection methods

- 2Principle and application of electronic halogen moisture Tester

- 3Difference between Halogen Moisture Meter and Karl Fischer Moisture Titrator

- 4Knowing Halogen Moisture Meter, reading this is enough

- 5Halogen Moisture Meter common faults and solutions

- 6What is the difference between a Moisture Meter halogen lamp and an infrared lamp?

- 7Tide Review: Inductive Moisture Meter MS310-S

- 8How to analyze the moisture content in drug powders?

- 9Several forms of paper moisture content