How to measure the hiding power of paint by contrast ratio method

Treat each test panel according to the provisions of GB/T 9271-2008 "Paints and Varnish Standard Test Panels" , and coat the tested product or system according to the method specified in the product standard. To control the thickness of the coating film , use a method specified in GB/T 13452. 2-2008 "Determination of Paint Film Thickness of Paints and Varnishes" to measure the dry film thickness of the coating, and prepare the putty film with a wet film preparer , Control the wet film thickness according to the specifications of the wet film preparer.

On a flat glass plate at least 6 mm thick, drop a few drops of 200 # mineral spirits, and spread the polycool film on it. With the help of the surface tension of 200 # solvent oil, the polycool film is attached to the surface of the glass plate, and air bubbles should not be mixed between the polycool film and the glass plate. If necessary, a clean to eliminate air bubbles. Stir the basecoat well to break up any thixotropic structure, but without creating air bubbles, and use immediately. According to the required thickness, pour 2-4 mL of color paint along the short line on one end of the polyhae film , and immediately use a suitable applicator to scrape at a uniform speed to spread the color paint into a uniform coating. Select applicators of different specifications that can give a wet film thickness range of 40-60µm or l00µm, and prepare two paint films each. The painted polycool film is fixed on a flat substrate and dried in horizontal conditions. Drying time or baking conditions, depending on the type of sample to be tested, shall be as specified in the product standard.

Before measuring the reflectance, each painted test panel should be dried under the specified conditions and placed for the specified time. Generally speaking, the dried painted polycool film should be kept at 23 ℃ ± 2 ℃ And relative humidity of 50% ± 5%, keep at least 24h, but not more than 168h. On the black and white glass plates (or ceramic plates), drop a few drops of 200 # solvent oil, and with the help of its surface tension, stick to the coated film in turn to ensure optical contact.

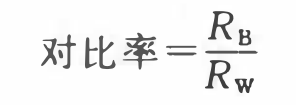

On the colorless and transparent polyester film (thickness 30-50μm), or on the cardboard with black and white evenly spread the tested coating, under standard conditions (temperature 23 ℃ ± 2 ℃' relative Humidity 50% ± 5%) for at least 24 hours. Then measure the reflectance of each painted polycool film in at least four positions, and calculate the average reflectance R B (on the blackboard) and Rw ( on the whiteboard) respectively, and then calculate the reflectance of each painted polycool film. Film contrast ratio R B /R w

Measure twice in parallel, if the difference between the two measurement results is not greater than 0.02, take the average of the two measurement results.

- 1Summary of determination methods for hiding power of coatings

- 2Pigment hiding power

- 3Determination of Coating hiding power

- 4GB/T 23981.2-2023: Paints and varnishes - Determination of hiding power - Part 2: Checkerboard method - Interpretation

- 5Concept, influencing factors and determination method of Coating hiding power

- 6Mayer Rods: The right-hand man for hiding power tests

- 7Coating performance testing: ensuring the efficiency and mass of the painting process

- 8Coating hiding power measurement

- 9Application of paint film Applicator in hiding power test