Surface Tension - Definition of Rings, Bubbles, Droplets and Plates

The definition of surface tension of a liquid is simple.

This is the force that keeps liquids from flying into space.

However, the measurement of surface tension can take many forms, which can be confusing. In order to make the content more clear, we elaborate two main measurement concepts in this paper: droplet-based measurement and force-based measurement.

Droplet-Based Surface Tension Measurement Concept

One of the concepts is based on the analysis of liquid droplets. This analysis can be:

1. Complex optical analysis of droplet shape,

2. Related to the pressure required to cause the bubble to burst, or,

3. Time dependent is the time it takes for a series of droplets to travel through a small diameter tube.

These methods either require advanced mathematical analysis or are difficult to implement.

Force-Based Surface Tension Measurement Concept

Another concept is based on the force exerted by the surface of a liquid on a foreign body. The basic task is to measure this force.

One of these techniques, known as the DuNouy ring method, begins with inserting a ring just below the surface of the liquid. The ring moves up through the interface between a liquid and air (or between a liquid and a lighter or denser liquid). Measures the force required to detach a ring from a surface or interface.

Another method of primary force is to use thin rectangles. The rectangle and testing process is called the Wilhelmy Plate. When lowering the plate into contact with the liquid, surface tension grabs the plate and pulls it downward. The magnitude of this force is used to calculate the surface tension of the liquid.

Bubble and Drop Techniques for Determination of Surface Tension

Bubble pressure, which we classify as drop-based testing procedures, includes spinning droplets, pendant droplets, bubble pressure, and studies of capillary rising and falling volumes. pendant

Spinning Drop is useful for liquids with very low surface tension. Pendant analysis has the advantage of characterizing network properties. Bubble manometers are especially useful for on-line measurements and time-segmented changes.

Other techniques including capillary rising and falling volumes are also used for special applications and education.

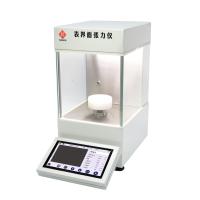

Surface tensiometer - DuNouy ring and Wilhelmy plate

Our goal is force measurement technology. Earlier measurements were made using DuNouy rings. The measurement starts when the ring is completely below the liquid level.

At that point the ring attached to the surface is edited and there are no forces on the ring other than gravity. A force-measuring mechanism is used to pull the ring up across the surface of the liquid. The retarding force begins when the ring approaches the surface and reaches a maximum when the ring is released from the liquid above the surface. This maximum force is the basis for calculating the surface tension.

Some early surface tension instruments used a torsional balance mechanism to determine this force. This mechanism is still used today. When calibrated, these torsion balances provide a sensitive, robust geomechanical construction for accuracy and repeatability. Newer designs use electronic balances to measure force.

Flat plate technology (Wilhelmy Plate) uses a thin rectangle usually made of platinum. Wilhelmy plate near surface When the plate is inserted into the liquid, surface tension pulls the plate downward. This force is used to calculate the final result. Usually an electronic balance is used to measure the force on the William's plate.

Surface tension is usually calculated in dynes/cm:

For the DuNouy ring method, the formula uses the inner and outer radii of the ring and the force required to pull the ring across the surface.

For a Wilhelmy plate, the formula uses the downward force of the liquid on the plate and the perimeter of the plate.

One of the new developments based on Wilhelmy's concept was the use of platinum rods instead of plates. These use the same force and girth coefficients to calculate surface tension.

Apparent and actual surface tension

Apparent surface tension was measured by the DuNouy ring method. A conversion formula is required to obtain the actual surface tension. For high surface tension liquids, correction factors range from 0.8 times the apparent surface tension at low levels to greater than 1.3 times the apparent surface tension. In many industrial applications, standards are based on apparent readings.

The Wilhelmy Plate result is the actual surface tension and does not require correction.

Application of DuNouy Ring and Wilhelmy Plate Instruments

Force-based tensiometers have a wide range of applications. Here is a sample application:

Testing Transformer Oil Power Transformers

Check Surfactant Content

Quality assurance and optimization of emulsifiers

Determining the effectiveness of the wetting medium

Check the plating solution

Summarize

In summary, we define two classes of surface tension instruments.

Droplet-based instruments, including the Spinning and Pendant Drop instruments, use sophisticated optical drop shape analysis. The vial instrument is suitable for in-line and portable use. There are many capillary action based instruments available for special measurements and education.

- 1Water surface tension measurement based on Electronic Balance

- 2Comparison of Liquid Surface/Interfacial Tension Testing Methods: Plate vs. Ring Method

- 3Selection guide for Surface Tensiometers

- 4Application principle and precautions of platinum ring Surface Tensiometer

- 5Coating surface tension and its effects

- 6Coating process surface tension factor

- 7Three commonly used detection methods for surface tension

- 8Ceramic ink-jet surface tension, viscosity and solutions

- 9Determination of interfacial tension and surface tension