Measurement principle and method of offset printing gloss

印刷制品表面光泽度是其产品品质的重要指标之一,一般情况下印刷基材和印刷工艺的不同很容易出现光泽度差异,本文主要介绍胶印光泽度的测量原理及方法。为了胶印外观质量,就可以使用光泽度仪来进行测量。

胶印光泽度如何表示?

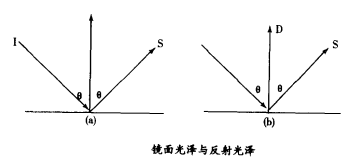

虽然光泽与物体表面的镜面反射有关,但也与观察者的生理和心理状态相互作用,因而不能单纯地以镜面反射的物理测量来表征。Hunter提出6种表示方法,其中镜面光与反射光泽两种适用于印刷业和造纸业,已被广泛采用。

镜面光泽(Gs)系物体表面镜面反射光量(S)与入射光量(I)之比,如下图所示:

当入射角采用85°时,测量结果称为光泽,一般用于描述低光泽表面。反射光泽(Gc)又称对比光泽,系物体镜面反射光量(S)与总反射光量(D)之比值。

胶印光泽测量应该选择什么角度?

使用光泽度仪测量胶印光泽。大多数光泽度仪是测量物体表面反射率,即镜面光泽,测量时所选入射角度不同,结果不同。入射角越大,镜面反射率越大,光泽越亮。

由此可见,光泽高低不仅取决于物体的表面特性,而且取决于测量角度。置于采用何种角度测量为宜,目前还没有通用标准。一般,对于高光泽表面采用小角度测量,如45°,对于低光泽表面则采取大角度进行测量,如60°、75°等。目前,许多光泽度仪的角度都是可调的,供任意选择。此外,Hammel还发现,光泽不仅取决于测量角度,还取决于照明和观察所采用的角度范围。

不同观察角度的反射率分布

As shown in the figure above, it is the relative amount of light reflected by 45° illumination and observation of printed matter from different angles. The two curves on the graph represent the case of printing with the same ink on coated and uncoated paper respectively. It can be seen from the figure that the surface of the coated paper print is smooth and uniform, and when observed at 45° (mirror direction), its relative reflected light has a high and narrow peak. Even slight changes in the angle can significantly affect the gloss value, so it needs to be very accurate. The reflectance distribution curve of non-coated paper prints is quite flat, and the maximum reflectance is not at 45°, but shifted to a direction of about 55°. This is because the rough surface of the paper forms many irregular slopes on the surface of the print. Top, when the parallel light beam is irradiated, the incident angle is not equal at each point, some are greater than 45°, and some are less than 45°. If the probabilities of the two cases are equal, the maximum reflectance shifts to a direction larger than 45° because more light is reflected at angles larger than 45°.

All in all, the angle of measuring gloss varies with the paper and ink used. Therefore, when using a gloss meter to measure, the corresponding angle should be selected according to different situations.

- 1Principle and Application of Glossiness Tester

- 2Working Principle and Application of Metal Gloss Meter

- 3Basic principle and application analysis of insulating paint gloss Detector

- 4Working principle and application analysis of film Glossmeter

- 5Principle and application analysis of microporous gloss meter

- 6 FZ/T 01097 Analysis of fabric gloss test method

- 7Evaluation and Application of Optical Properties of Powder coatings

- 8Coating coatings - Determination of surface gloss and Gloss meter

- 9The Importance and Method of Gloss Measurement of Paint Film