How does an ultrasonic cleaner work?

An easy way to illustrate how ultrasonic cleaners work is to compare them to automatic dishwashers, but with some improvements. Automatic dishwashers are much the same as ultrasonic cleaners, combining water and detergent to remove grease, dirt and other contaminants from the items being cleaned.

Applications for ultrasonic cleaners include cleaning precision optics and laboratory glassware. Ultrasonic cleaners are often used instead of cleaning pots and pans, and are often used to clean other metal or plastic products that are difficult or impossible to clean by other methods.

Working principle of ultrasonic cleaning machine

Unlike the high-pressure water jets used in automatic dishwashers, ultrasonic cleaners work by harnessing the force of exploding (not exploding) tiny air bubbles in a process called "cavitation." The procedure is explained below. It's also different to use biodegradable cleaning fluid concentrates that are specifically designed for the cleaning task at hand. You can learn more about how these work in our how to choose a cleaning solution formulation article. Instructions for use of these solutions are provided by the manufacturer.

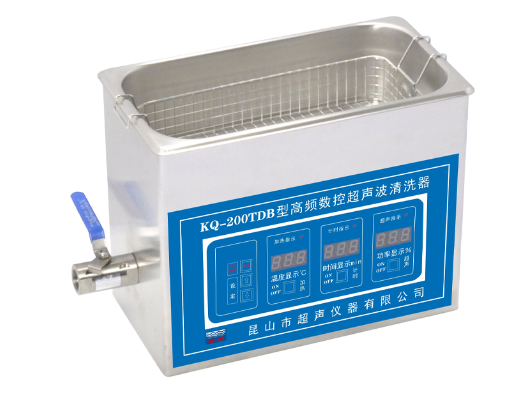

First, the components of the ultrasonic cleaning machine

Understanding how an ultrasonic cleaner works requires understanding its components. Search for these cleaners to discover the entire model and price range. But, fundamentally, these units include:

Tank for cleaning fluid. Tanks should be stainless steel; their volume depends on the size of the object to be cleaned

Ultrasonic transducers that cavitate and bond to the tank bottom

Generator powers the transducer

Controls range from simple on and off switches to sophisticated microprocessors controlling wash time, frequency sweep, pulse, degassing, temperature, ultrasonic frequency, ultrasonic power, automatic safety shutoff and other improvements.

These cleaners range from small benchtop units to huge multi-gallon industrial cleaners. The capabilities of cleaners have little or no impact on the functionality they provide, and the decision about the functionality required rests with the buyer.

2. What does the ultrasonic transducer do?

There are two basic types of sensors: piezoelectric (aka electrostrictive) or magnetostrictive, but they function the same. Excited by an electric current supplied by an ultrasonic cleaner generator, they vibrate at ultrasonic frequencies, causing the bottom (and, if applicable, the sides) of the tank to vibrate, acting as a diaphragm. This vibration creates a vacuum bubble that bursts (not explodes) on contact with the contents of the ultrasonic cleaner tank, which explodes and carries away the contaminants. There are also immersion sensors. Ultrasonic frequency is an important part of how an ultrasonic cleaner works, as discussed below.

3. How to choose the frequency of ultrasonic cleaning machine

Ultrasound is generally defined as sound beyond the range of human hearing. Low frequencies (such as 25,000 cycles per second or 25 kHz) produce larger bubbles that burst more violently than those produced at higher frequencies such as 37, 80, or 130 kHz (which produce a gradual, gentle cleaning action). For example, the radius of a cavitation bubble generated at 37 kHz is about 88 microns. 41 microns at 80 kHz.

As a bit off topic, the implosion of the cavitation bubble produces a shock wave that radiates from the collapsed site and generates temperatures in excess of 10,000°F and pressures in excess of 10,000 psi at the site of the implosion. However, the process is so quick that there is little heat build-up and no damage to the parts being cleaned. That said, never touch a running ultrasonic cleaner to inspect, relocate, or remove the part being inspected.

Removing gross contamination from solid parts such as metal or cast metal requires less frequent use of cleaners. Softer metals, plastics and polished surfaces should be cleaned more frequently. In addition to protecting polished surfaces, smaller air bubbles can better penetrate tight areas such as seams, crevices and blind holes. If you want more information on this specific topic, check out our article on choosing an ultrasonic cleaner frequency.

It is our opinion that the decision to purchase an ultrasonic cleaner should be made on more than just price.

4. Why do you need an ultrasonic cleaner basket

Ultrasonic cleaners work better when cavitation bubbles enter all surfaces immersed in the cleaning solution. This is best done when the parts are suspended in the solution, rather than resting on the bottom of the wash tank. In most cases, a basket is used to hold the part at an appropriate distance from the bottom of the tank. Baskets are usually stainless steel mesh with mesh or solid stainless steel walls. Small parts such as screws can be placed in a fine mesh basket that can be placed in a slotted basket or suspended in the solution. Very large parts can be suspended from the overhead support to the correct cleaning depth.

why is it like this? In addition to advocating for more effective cleaning of the basket, it is important to keep the parts out of contact with the bottom of the tank, where vibrations at ultrasonic frequencies would cause wear and tear on the tank. Ultimately, this can cause holes to form in the tank and cause vibration to damage the parts being cleaned.

This is important when considering the size (container size) of your ultrasonic cleaner. Ultrasonic cleaners work better when the part is completely submerged in the solution. In addition to the apparent width and length of the container (more precisely the basket), there is also known as the working depth of the unit, ie the distance between the bottom of the basket and the surface of the cleaning fluid. Keep this in mind when choosing your equipment.

5. Ultrasonic cleaner function

Ultrasonic cleaners have the ability to make cleaning faster, more effective and therefore more effective, so the results are better. Earlier we mentioned that the base unit can only be equipped with a simple switch, but pointed out that other functions can achieve the desired effect. Here is a brief overview of these:

A timer allows you to set the length of the cleaning cycle (usually gained through experience), so you can set the time and perform other tasks while the cleaning is happening.

The temperature control allows you to set the recommended cleaning temperature based on the cleaning solution provider's recommendations. Some appliances are equipped with a function that starts automatically when the set temperature is reached.

Sweep mode produces small ± changes in ultrasonic frequency, avoiding so-called hot spots (which can damage high cavitation action), dead zones (low or no cleaning action) and harmonic vibrations which can damage precision components such as printed circuit boards. Component. The opposite of scanning is "normal" or "fixed frequency", which is used in laboratories for sample preparation. Some units offer both "scan" and "normal" options.

Degassing mode removes air trapped in fresh cleaning solution. Residual gas will affect the cleaning effect. Running the device empty will eventually degas the solution, but it will take longer.

Pulse mode provides pulses of increased ultrasonic power to remove stubborn contaminants. Pulses can also be used to degas solutions.

The ultrasonic frequency can be changed in some units, so that the user can set the frequency suitable for the work, thus expanding the use range of the ultrasonic cleaner. For example 25/45 kHz, 35/130 kHz and 37/80 kHz

Some models can control the ultrasonic power and also allow the user to set the cleaning parameters fine for the job at hand. These usually allow increases from 10% to 100%.

The safety cut-off feature helps protect equipment and contents from excessive temperatures and prolonged cleaning cycles, which can cause cleaning fluid to evaporate below recommended levels.

Manufacturers offer a number of accessories that help ultrasonic cleaners work better and more efficiently. Examples include acoustic covers, cooling coils, flask racks, and cleaning fluid filters for larger components, which are partially covered below.

6. Where will the ultrasonic cleaner go?

When it comes to automatic dishwashers, the answer is simple. For your ultrasonic cleaner, they stay in solution. Contaminants removed during cleaning either float to the surface, sink to the bottom or remain in suspension. Our previous reference on cleaning solution selection covers this in detail.

Contaminants floating on top should be skimmed off and left for later disposal. Some tanks are equipped with skimmers and weirs to direct floating contaminants to collectors. Larger units can be equipped with filters to extend the life of the solution. The point is that eventually the efficiency will drop and the solution will need to be drained and disposed of with the removed contaminants according to local regulations. When that time comes, take the time to clean the ultrasonic cleaner tank according to the manufacturer's directions. Prepare a fresh solution and degas it, and you can continue cleaning.

- 1Ultrasonic cleaning machine application field

- 2How to choose an explosion-proof ultrasonic cleaner?

- 310 Tips for Ultrasonic Cleaner Choice