How to Choose a Film Applicator? Film Applicator Principles, Applications and Selection Steps

The principle of film coating machine

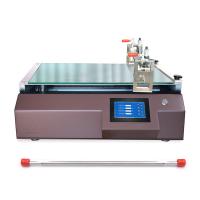

The film coating machine is a film coating equipment that assists technicians in precise film production. It simulates manual operation to provide a film coating environment with more uniform force and a more constant speed. It is generally equipped with a preparer and a wire rod to control the film thickness.

The coating machine itself does not control the film thickness, and the control of the film thickness is determined by the scraper/wire rod of the optional coating machine.

Classification of film coating machine

Application of film coating machine

Coating research and development

Coatings research and development labs use compact Film Applicators to create consistent test patterns for research after different formulations. Parameters such as opacity, spreading rate, color and hiding power need to be evaluated at a controlled film thickness.

raw material

Manufacturers of raw materials in the paint and coatings industry, such as binders, pigments, additives, colorants, solvents and resins, require reproducible sample diagrams in order to define the role of their products in paint formulations in their R&D laboratories.

Battery research and development

The industry is eagerly seeking better and environmentally friendly batteries. Thin-film technology plays an important role in this research. These labs use automated Film Applicators to apply thin films, such as electrolytes from thin metal plates.

Cosmetics produce reproducible samples

Create reproducible samples to measure cosmetic and skin care product properties such as hardness, breaking strength, consistency, compaction strength, hiding power and opacity, spreading ability, tack, dry and cure time, color, gloss and more.

adhesive manufacturer

In the research and development and quality control of the adhesive industry, the importance of testing samples with accurate film thickness to define and guarantee the functionality and strength of adhesive materials cannot be overemphasized. Using a heated automatic Film Applicator, "standard" bond strength can also be assessed at different temperatures.

How to choose?

1. Determine the coating material

What kind of material you are painting, the material is different, and the collocation considered will be different. Use a scraper for high viscosity, use a wire rod for low viscosity, generally use bottom heating for heating, and top heating for quick drying.

2. Determine the coating substrate

Special attention should be paid to the substrate of the coating film. If the film cannot be smoothed, vacuum adsorption must be selected; if it is a hard material such as tinplate, it depends on whether it is smooth or rough at the time. If the substrate is too small, it is impossible to use a scraper, because The scraper is based on the height difference provided by the weight at both ends. In this case, it is better to choose a wire rod. But if the viscosity is too high, it is necessary to provide samples or wire rods for trial. Under normal circumstances, vacuum adsorption is used for film; normal glass plate is sufficient for paper.

3. Determine the format size

Due to the different requirements of some customers, the width and length of the coating film will be required, and the approximate length can be selected according to the customer's requirements.

Generally speaking, the film coating machine is mainly to reduce the error caused by manual film coating and improve the repeatability effect. The difference between imported and domestic ones is the motor, and the other is the film-coated board. The smoothness and straightness of the board directly affects the film accuracy and effect of the coating film. The motor mainly affects the film due to vibration and other factors, and there is also the problem of life. One of the more interesting things is that in order to reduce the impact of the vibration caused by the motor, many manufacturers suggest that the film coating machine with vacuum adsorption function should be equipped with an external Vacuum Pump. Although this is not beautiful, it is indeed a good way to reduce the vibration of the film coating machine itself. method, you may wish to try.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application of laboratory coater in LED fluorescent film Spreader

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Scraping machine selection case: film substrate large size high accuracy scraping solution

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research