Several main items of powder coating performance testing

(1)流度

粉末的流度是一个重要参数,因为它是粉末涂料输送和使用的主要因素。流度可以用不同的方法测定,在所有的测试方法中均需要准确地控制温度和相对湿度。

较实用的Sclier流度测定方法是荷兰全国科学研究中心所发表的一个试验方法,其测试仪器已由法国Sames公司制造。

其测试方法是:称取一定质量的粉末(约250g),放在一个直径为100mm的团柱状聚氯乙烯容器内,容器有一个用青铜烧结的多孔底,空气以200L/h的速率送入容器内。粉末被流化1~10min后,通过容器壁上一个直径为4mm的孔,使粉末流出30s,测出流出的粉末质量即可。

流度系数R,可按下面公式算出。

式中:m——流出的粉末质量;

h1——流态化时粉末层的高度;

h0——容器内粉末的原有高度。

在测定流度系数时,可以说一个良好流动的粉末,应具有好的数据重现性。评述粉末流度的效果,可参考下列数据。

| 流度系数 | 评述 | 流度系数 | 评述 |

| >180 | 很好 | 80~120 | 中等 |

| 140~180 | 好 | <80 | 差 |

| 120~140 | 合格 |

(2)粉末粒度的分布

常用的测试方式是干筛法,其方法是将一定数量的粉末,在规定的时间和力的作用下,通过具有不同筛孔的一组筛子,然后称量停留在各筛子中的粉末质量,这样即可用质量百分数来表示粉末在某一筛孔的组成。

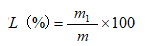

质量百分组成,可用下式表示:

式中L——各筛子粒度分布,%;

m——粉末总质盘,g;

m1——各筛子上剩余粉末的质量,g。

(3)凝胶时间

凝胶时间(或称胶化时间)是测定粉末涂料活性程度的有效方法。

一个简单的测试方法是将2g粉末涂料放到一块调到特定温度(如:100℃±2℃)的热板上,然后用一根木制的舌板沿着约25mm大小的圆环形路线不断进行移动,当将舌板提起约50mm高度后,若能形成一条连绒细丝,此点即为凝判点,从粉末涂料熔化到凝致点所需的时间就称为凝胶时间,计量单位用s来表示。

(4)贮存稳定性

Weigh 10g of powder, put it into an uncovered aluminum dish with a diameter of 50mm, and then place it at 40 °C ± 3°C and a relative humidity of 95% ± 5%, check whether it is agglomerated after 48 hours, and measure the coagulation Glue time and spraying sample, and compare the original powder situation.

( 5 ) Melting point

The melting point of powder coatings can be determined using a Kofler Hot Plate. The method is to spread the powder on a narrow metal strip, and the temperature of the metal narrow strip has a uniform change from one end to the other , so that the melting point range of the powder coating can be accurately observed.

It is also possible to use a capillary tube to determine the melting point of powder coatings according to the general melting point determination method.

(6) Moisture content

Dissolving the powder coating in anhydrous dioxane and using the Karl-Fischer moisture determination method can accurately measure the trace moisture contained in the powder coating.

(7) Density and relative density

①Apparent density: Measured according to method A of ASTM D 1895.

② Volume factor: measured according to ASTM D 1895.

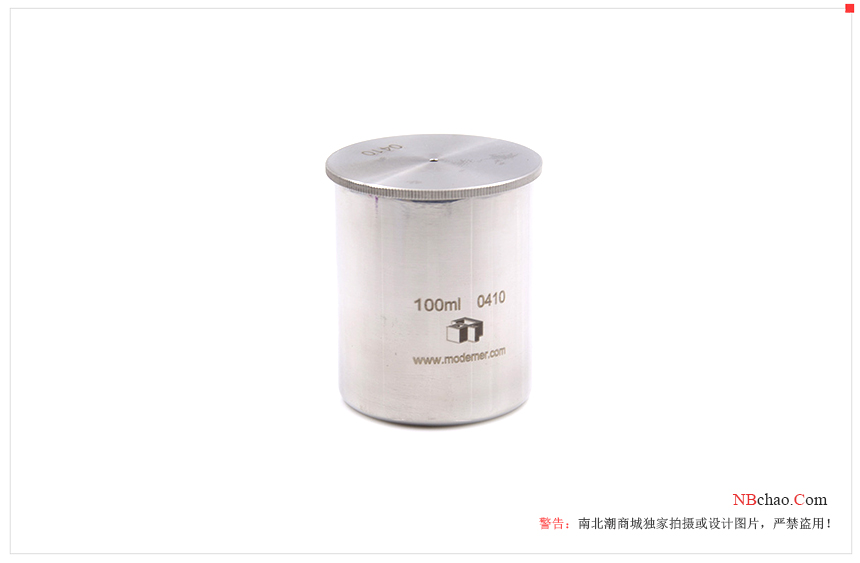

③Relative density: Measured according to ASTM D 153 or as follows: Gallon weight cup can be used instead of pycnometer. Due to the wide mouth of the measuring cup, it is easy to invert the powder without loss. In addition, it is easier to remove the incoming air by using a glass stirrer, and it is easier to wet it with gasoline (or other suitable carrier can be agreed between the buyer and the seller). Care must be taken to return the powder particles attached to the glass rod to the gallon weight cup to ensure the accuracy of the method.

- 1Determination of thermal plasticity Resin melt flow rate

- 2Molecular weight and distribution characteristics of polyester resin in thermosetting powder coatings

- 3Density Determination Method and Application

- 4Determination method of cone-plate viscometer and its application

- 5Thermal plasticity polyvinyl chloride (PVC) powder coatings in highway engineering: technical requirements and inspection methods

- 6Determination of compatibility of powder coatings: methods, effects and applications

- 7Evaluation of flowability of powder coatings: key factors and significance

- 8Evaluation and Application of Optical Properties of Powder coatings

- 9Importance of powder coatings curing degree and detection method