How to keep the film sagging improved and maintain a suitable rheological state?

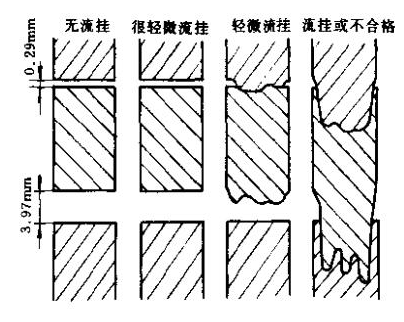

The color paint is applied to the surface of a vertical object. During the formation of the coating film, the wet film flows downward under the influence of gravity, forming an uneven coating film, which is called "flowing" or "sagging", as shown in the figure .

Visual grading chart for determining the tendency of coatings to sag when applied to vertical substrates

The wet film should have a certain degree of flow in order to achieve satisfactory leveling, but the transitional flow will form a flow and fall sickness.

The reason is that it is related to the rheological properties of the paint, and the paint sinking is related to the viscosity of the paint. During construction, it is required that the brush marks disappear as soon as possible, and it is hoped that the paint sinking will stop as soon as possible. How to solve the contradiction is a difficult problem. Newtonian paint systems are difficult to solve, and non-Newtonian paint systems are not easy to solve this problem satisfactorily.

To make the coating film flow properly, it is necessary to make the rheology of the coating in the most suitable state. To prevent the occurrence of sagging, the most important thing is to control the viscosity of the paint at the brushing shear rate. In addition, the type of solvent used is also an important factor, because it affects the change of viscosity.

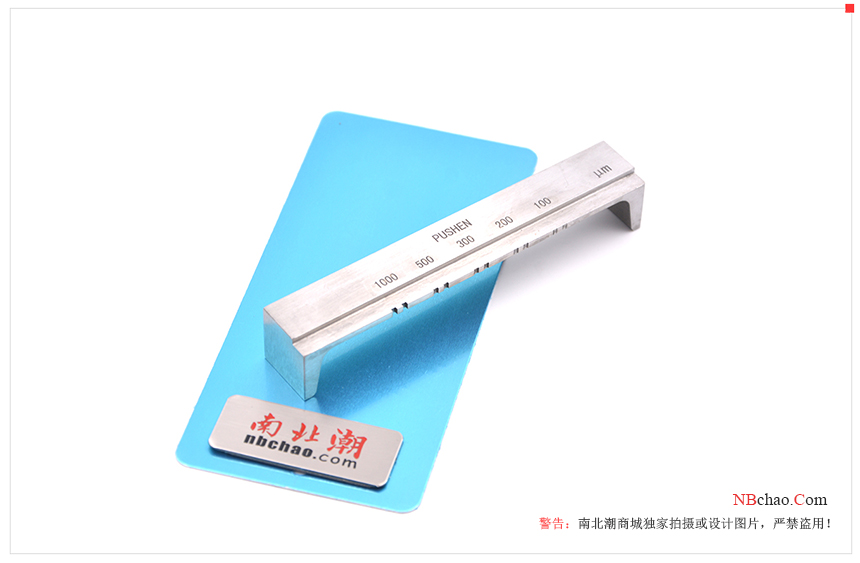

When using the spraying method, the thickness of the coating film must be well controlled. If the spraying is too thick or the volatilization rate of the solvent is too slow, it will also cause flow. A film thickness without obvious sag is called "sag limit", which is proportional to the yield value. Therefore, to increase the "sag limit", you can use the method of increasing the yield value, or you can add an appropriate amount of rheological additives, for example. Organic modified bentonite B entone 36 and so on.

When the thermosetting coating is baked and dried, the wet film often sags due to the decrease in viscosity caused by heat, which is called "baking sag ". It is also a good way to prevent sagging by adopting the "wet on wet" coating process during the drying process.

In addition, the state of the substrate and the surface of the bottom layer, as well as the method of construction and coating and the environmental conditions of the atmosphere will all affect the occurrence of flow fall .

- 1Sag problems and their solutions

- 2Application and significance of Sag Tester

- 3what is the coating Leveling and Sag resistance

- 4How to assess the sag resistance of paints and varnishes according to ISO 16862

- 5Why does the coating have orange peel defects? How to solve sagging and leakage?

- 6Wetting, coalescing and hanging of paint rheological phenomena

- 7The difference between ink fluidity and fluidity

- 8Common paint film defects and solutions of container coatings

- 9Determination of leveling and sagging of coatings