What kind of Air Compressor do you generally choose for air Spray Gun spraying?

The maximum pressure of the Air Compressor is 0.7MPa (no load). Air Compressors used for painting are generally divided into air pump type and screw type. The noise, energy consumption and oil-water impurities of the spiral type are relatively low, and most of them have the functions of . Therefore, the spiral-type primary oil-water separator and air storage cylinder can be omitted. The air pump type requires a refueling water separator.

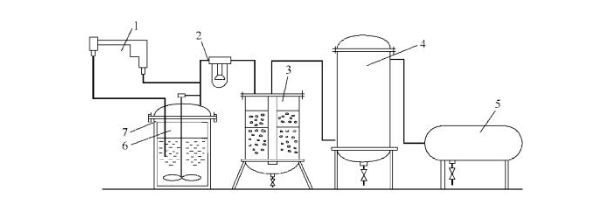

Figure 1 Schematic diagram of air spraying system 1 — Spray Gun; 2 — secondary oil-water separator; 3 — first-stage oil-water filter; 4 — air storage cylinder ; 5—air compressor ;

Large-scale Air Compressors produce compressed air by the air pump piston, the temperature is high, and the oil and water impurities contained in it are more, so it needs to be cooled to room temperature through the air storage cylinder, so that the oil, water, and impurities dissolved in the air at high temperature are precipitated and sink to the bottom of the cylinder . The air storage cylinder can also play a role in stabilizing the pressure, but it causes the air pressure inertia to increase, and the air pressure rises slowly. After work, the compressed air in the air storage cylinder will be emptied, which wastes energy. Small Air Compressors (less than 0.6m 3 and 1m 3 ) do not need an air storage cylinder during discontinuous operation. The compressed air in the air storage cylinder goes into the primary oil-water filter to filter oil and water, and then enters the secondary filter to further remove oil, water and impurity particles, and then enters the Spray Gun to complete the air spraying. The secondary filter generally uses a refrigerated compressed air dryer. The oil content of compressed air after secondary purification is less than 10 -7 .

- 1Application and classification of lame plating technology

- 2Basic Principle and Application of Permanent Magnet Air Compressor

- 3Types of Spray Guns commonly used

- 4How to properly operate and maintain the Spray Gun?

- 5Why does the coating have orange peel defects? How to solve sagging and leakage?

- 6What are the tips to prevent sand inclusion and dry spray of paint film?

- 7The relationship between Spray Gun caliber, paint viscosity and coating type of electric airless sprayer

- 8Spraying of power tools - Spray Guns

- 9Several solutions for double coating