What factors will affect the coating effect of curtain coating?

The main process parameters affecting curtain coating are paint viscosity, paint pressure, slit width and conveyor speed, among which the slit width has a particularly large impact on curtain stability and coating amount.

①Paint viscosity

When the paint is too thin, the curtain is easy to break, within the range of 30-150s (coating - 4 cups), it can ensure a stable curtain for various paints. The viscosity of nitro paint and general paint is 25~30s, and the viscosity of polyester high solids paint is 30~50s. The metal surface should be coated with paint for 30~50s, but the porous wood surface should be painted for 70~100s to maintain a good decorative appearance.

②Slit width

The adjustable range of the slit is 0.3-1.2mm. With constant paint pressure, the curtain . When the slit is too narrow, the amount of paint flowing out is small, causing the curtain to break; when the slit is too wide, the curtain falling speed is not suitable for the speed of the fast conveyor, resulting in uneven coating. The suitable range of the slit is generally 0.5 ~ 0.8mm, and according to the viscosity of the paint, adjust the width of the slit to make it have a suitable outflow.

③Paint pressure

Paint pressure has a great influence on outflow velocity. The paint pressure inside the curtain head is generally controlled at 10-20kPa .

④Conveyor speed

Conveyor speed can be adjusted to vary coat weight. The conveyor is steplessly adjustable , but the coating film is discontinuous if the speed is too fast, and the coating film is too thick if the speed is too slow, generally adjust within 70~90m/min, and the corresponding coating amount is 100~70g /m 2 .

Curtain coating process parameters are adjusted according to the following procedure: select the coating type according to the coating quality requirements → determine the coating viscosity according to the coating film thickness and material → determine the slit width → appropriately increase the coating pressure to ensure continuous curtain → adjust the conveyor speed , so that it has a suitable coating amount. Curtain coating needs to be equipped with drying equipment, and is especially suitable for quick-drying coatings, which can greatly shorten the length of the conveyor chain.

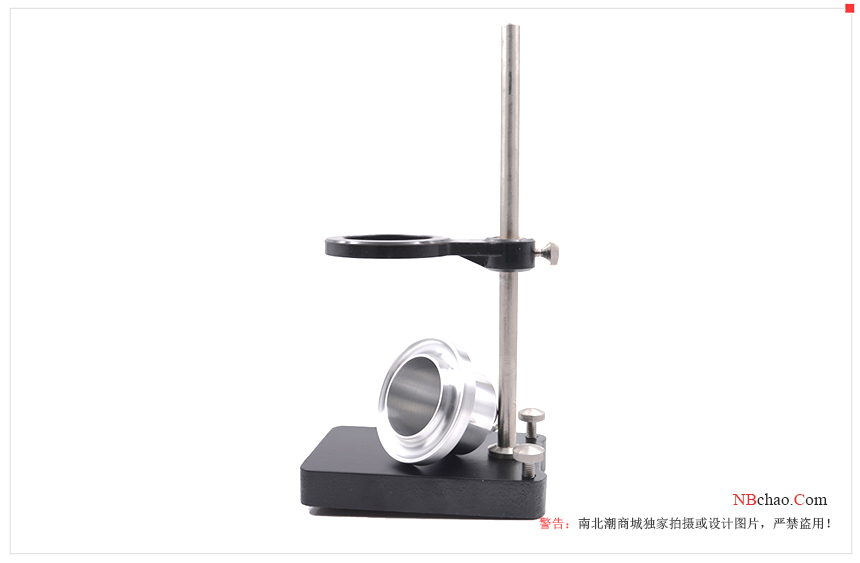

- 1The principle of small hole viscometer

- 2Yonglida copper viscosity cup beauty appreciation

- 3What is dip coating? How to dip coating?

-

-

-

-

-

JFL QND-4 coated four cups$ 128.00

-