What factors affect the tensile properties of sealants?

There are many factors that affect the tensile properties of a sealant. In addition to the performance of the sealant itself, such as wrong formula, unstable performance of raw materials, storage of the sealant itself, improper storage or too long storage period, it is also related to the sample preparation process, such as rubber mixing (grinding) process, vulcanization Process and other factors are related to many factors such as ambient temperature, humidity, cutting knife, sample thickness, tensile speed and force machine during the sample testing process.

(1) Test temperature

Even the samples made in the same batch have different tensile strength and elongation at break when tested at different temperatures. Generally, as the temperature increases, the tensile strength decreases and the elongation at break increases. Therefore, the test environment temperature should be reported in the report.

(2) Tensile speed

The standard stipulates that the tensile speed is (500±50)mm/min. If the tensile speed is accelerated, the tensile strength will be high, otherwise it will be low. This may be caused by relaxation of the vulcanized rubber in the sealant during stretching. The faster the stretching speed, the shorter the relaxation time, and the smaller the stress reduction caused by relaxation, so the tensile strength is high.

(3) Sample width and thickness

The wider the sample width, the lower the tensile strength. This is because the probability of defects increases and the stress at the edge of the width is greater than the stress in the middle of the sample, which leads to early fracture due to stress concentration. As the thickness increases, the tensile strength and elongation of the sample decrease. This is because the probability of defects increases as the thickness increases. The thicker the sample, the more recessed it is, and its actual cross-sectional area decreases. Due to the superposition of the above two factors, the tensile strength and elongation at break decrease. The impact is more obvious.

(4) Bubbles

Because the air bubbles in the sealant cannot be discharged, the actual cross-sectional area is small, and the stress is easy to concentrate on the defect, which reduces the tensile and tear elongation.

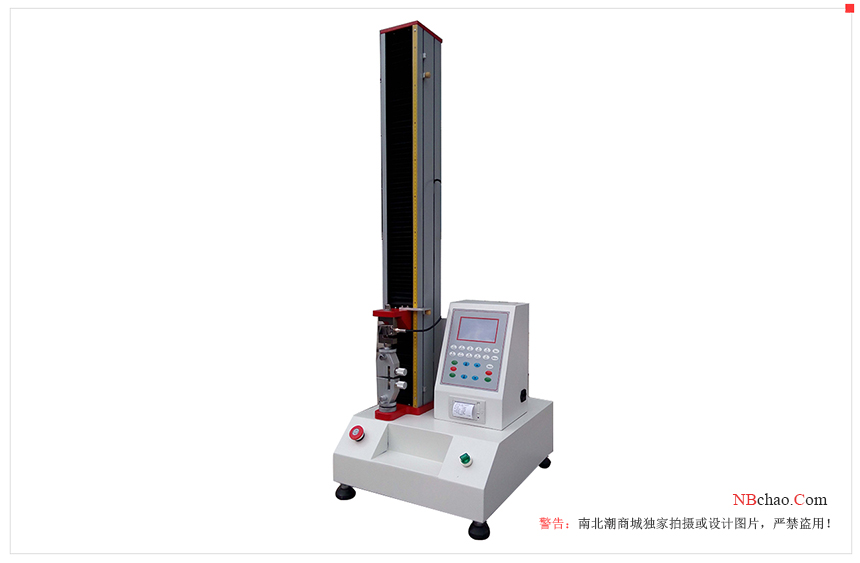

(5) Tensile testing machine

To test the tearing strength of the sealant, it is recommended to choose a non-inertial electronic Tensile Testing Machine. Inertia: pendulum type (also divided into two types: lever pendulum type and pendulum type) Tensile Testing Machine. Due to the influence of friction and inertia, different results are easily obtained from each other. Due to the overhanging beam sticking machine: the blade is displaced; the pendulum is easy to be heavy; the distance between the swing rod and the rack is too large or too small; the lever fulcrum bearing is corroded or oily and dirty, causing the swing rod to be inflexible; The rack and the pulley are not in a straight line when running; the dial pointer, especially the driven needle and the dial have high friction resistance; the friction wheel of the transmission system wears too much, which reflects the noise, and the falling speed of the lower chuck increases with the load. And it becomes slower and the gap between the lower chuck table and the prismatic track is too loose or too tight. As a result, the lower chuck swings left and right, the upper and lower jaws cannot be kept on the same axis or the resistance is large, which affects the descending speed, etc., resulting in the following errors that may occur when using a mechanical Tensile Testing Machine.

The error generated when reading the data from the force measuring dial due to the deviation of the Tester's viewing angle; the zero position of the pointer on the force measuring dial is not adjusted properly, resulting in the test data being too large or too small; due to the mechanical device during the test The accuracy is not high, the static calibration and the actual test. The error caused by the inert action of the mechanical transmission; the error caused by the large inertia and friction of the force measuring system of the above instrument itself and the transmission system.

- 1Tensile machine application in various industries

- 2Technical analysis of key parameters of Tensile machine: Scientific selection from force measurement accuracy to Power system

- 3Tensile machine purchasing guide [dry version]

- 4Talking about the performance test of epoxy resin film coated on PET

- 5ASTM D5019 Single-layer roofing film reinforced CSM board (chlorosulfonated polyethylene (PE)) standard interpretation

- 6Common problems and solutions in tensile testing

- 7What is tensile strength testing and which products can be tested?

- 8Factors Affecting the Performance and Accuracy of Tensile Testing Machines

- 9Classification of Tensile Testing Machines

-

-

-

CHINA NBC-1024-2 Tensile Tester 5T$ 6635.00

-

-

-