Three test items and methods for light resistance of coating films

In addition to the external force, the coating film is affected by light, heat and electricity during use, which will also change the strength and appearance of the coating film. Test the resistance of the coating film to these factors according to the product requirements. Common testing items and methods are listed below.

Light fastness refers to the ability of the coating film to maintain its original optical properties such as color and gloss after being irradiated by light, which is further divided into gloss retention, color retention and yellowing resistance. The coating film changes under the irradiation of mouth light, but it takes a long time. Usually, artificial light sources are used to test the light resistance of the coating film to accelerate the change of the coating film and shorten the detection time.

1. Gloss retention

Refers to the ability of the coating film to maintain its original gloss when exposed to light. The common detection method is to cover the ... part of the coating film sample to be tested, and then irradiate it under sunlight or artificial light for a certain period of time. Use a photoelectric Glossmeter to measure the gloss of the unirradiated and irradiated parts, and express the result of gloss retention by their ratio.

2. Color retention

Refers to the ability of the coating film to maintain its original color when exposed to light. The usual detection method is to compare the difference in color between the irradiated coating film and the unirradiated coating film, and measure it with the naked eye or a Colorimeter. The Japanese JIS standard stipulates that the rotary fading Tester with a 400W high-pressure mercury lamp should be used for inspection. The temperature rises when the light is irradiated, and ventilation and temperature adjustment are required.

3. Yellowing resistance

The coating film of the paint containing grease often produces yellowing during the hanging process, and even some white paint standard boards will gradually produce yellowing during storage in the dark. Most of the reasons are that the decomposed substances generated during the drying process and continuous oxidation of the oil contained in the paint are yellowish, which is easier to detect on light-colored paint. In order to prevent and judge the occurrence of yellowing in advance, it is necessary to inspect this item.

First, the sample is coated on a frosted glass plate, dried and left to stand, then placed in a desiccator filled with saturated potassium sulfate solution, taken out after a certain period of time, and the three-stimulus values X, Y, and X of the color of the coating film are measured. Z. Then calculate the degree of yellowing (D) according to the formula:

D=(1.28X-1.06Z)/Y

It is also possible to put ammonia water with a concentration of 2% to 5% at the bottom of the dryer, make the paint film experience a certain period of time in the vapor generated by ammonia water, and then take it out for inspection. Visually or measure the yellowness value. It is better to carry out the test together with a coated test panel with known yellowing resistance for reference.

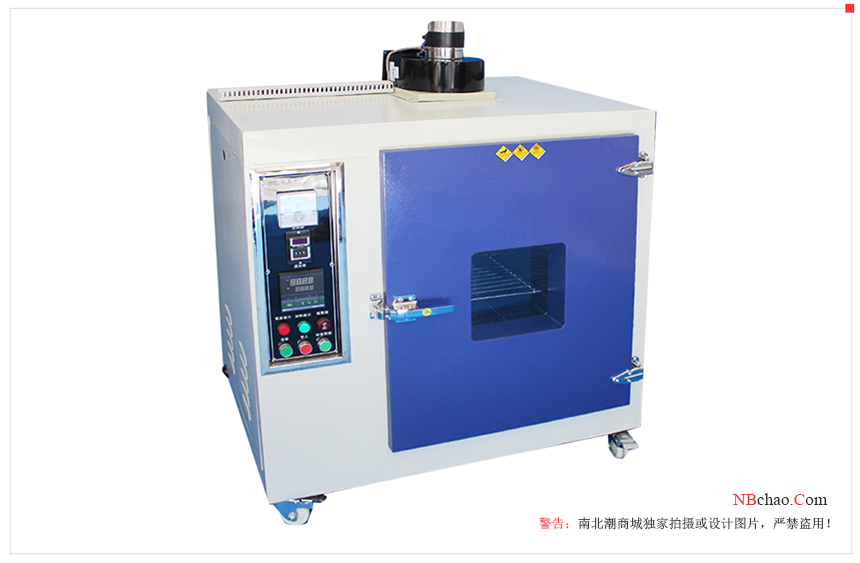

- 1Non-yellowing Test Chamber comprehensive analysis: test principles, scientific definitions, and professional selection guidelines

- 2Test method for yellowing resistance of polyurethane synthetic leather

王学川;周志军;张哲;强涛涛 - 《皮革与化工》

- 3Analysis and Discussion on Yellowing of Polyurethane Synthetic Leather

王学川;周志军;张哲;强涛涛 - 《皮革与化工》

- 4How to measure the yellowing resistance of films?

- 5How is the yellowing resistance of films determined?