Test method and precautions for use of ink viscosity meter

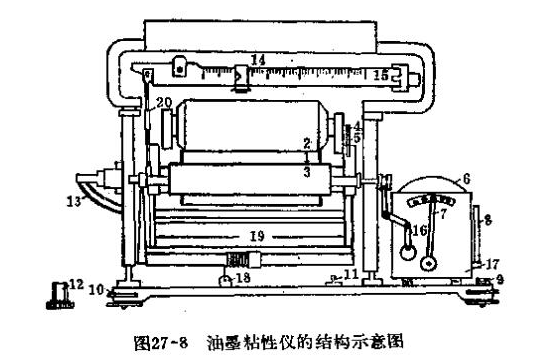

The ink viscosity meter (see picture) should be placed on a level and stable workbench, and adjusted by 10 to make the instrument in a horizontal soft state (observable from level 9).

After turning on the power, adjust the temperature of the thermostat Water Bath to 32°C, and keep this temperature throughout the measurement.

Put the shift lever 7 on the low speed position (if it is the B-45 type, then put it on the position of 400 rev/min). Lift the handle 4 so that the synthetic rubber wheel 2 rests on the metal rod 1. The ink-repellent glue 3 with a pressure of 8 pounds is also pressed on the metal roller 1, and the three rollers are in contact with each other at this moment. Turn on the motor switch and make the rollers rotate for 15 minutes to increase the temperature . Turn off the motor.

Put the vernier 14 on the "0" position of the scale 15, press the brake lever 11, and observe whether the scale 15 is balanced. If it is unbalanced, the balance screw (not marked) connected to the metal roller 1 on the left side can be omitted to make the scale 15 in a balanced state, which is the first balance (that is, the balance of the instrument itself), and the motor is turned off.

Fill the ink absorber 12 with ink, then evenly coat the ink on the synthetic rubber roller 2, and turn the motor shaft by hand to make the roller rotate and the ink can be evenly distributed (coated) on each roller. The ink layer was uniformly spread to a thickness of about 0.0005 inches.

Turn on the motor, make the roller rotate for one minute, stir the brake lever 11, move the vernier 14, and make the scale 15 in a balanced state, which is the second balance. The number at the position of the cursor is the viscosity of the ink. Turn off the motor.

Precautions

1. Turn the gear box to the position where it is easy to move by hand, and then turn on the motor. After the motor is started, do not move the shift lever to avoid damage to the gears.

2. The ink must be gently and evenly coated on the synthetic rubber sheet 2 with an ink absorber. 3. After the test is completed, each sheet should be wiped clean. The soft cloth used for wiping must be clean and free of dirt, so as not to scratch or damage the sheet . And make each of the three sticks out of contact.

4. The two ends of the ink distribution roller should be lubricated frequently.

5. If you want to measure the color flying of the ink, you can put a piece of white paper on the beam under the metal roller 1, and you can observe the color flying of the ink.

6. If you want to measure the viscosity of the ink at medium speed or high speed, you can move and change the shift lever 7 to make it in the desired position.

7. This operation method is only applicable to the standard ink viscosity meter.