Common test performance items of paper

The mechanical properties of paper refer to its resistance to external forces under certain conditions. Since fibers are most sensitive to humidity and temperature, the strength of paper is generally measured under constant temperature and humidity conditions with a relative humidity of 65% and a temperature of 25°C.

The mechanical indicators of paper mainly include tensile force, elongation, breaking length, bursting resistance, folding resistance, tearing degree and other items.

Tensile force (also called tensile strength) refers to the maximum load that paper can withstand until it breaks. The unit is kilogram. It can be measured directly from the broaching machine. The elongation of the paper can also be measured on the tensile machine at the same time. The physical meaning of elongation is: the percentage of the elongation of the paper when it is stretched to break and the original length.

Fracture length is a very important data for roll paper printing. It cannot be measured directly, but is calculated based on the quantitative, tensile and other data of the paper. The breaking length indicates the relative value of the strength of the paper. It is the calculated length when one end of the paper is fixed and the other end hangs freely and sags due to the weight of the paper itself. Generally, newsprint requires a breaking length of more than 3,000 meters. The breaking length of the paper is related to the following: the average length and strength of the fibers, the bonding force of the fibers, and the interweaving conditions of the fibers.

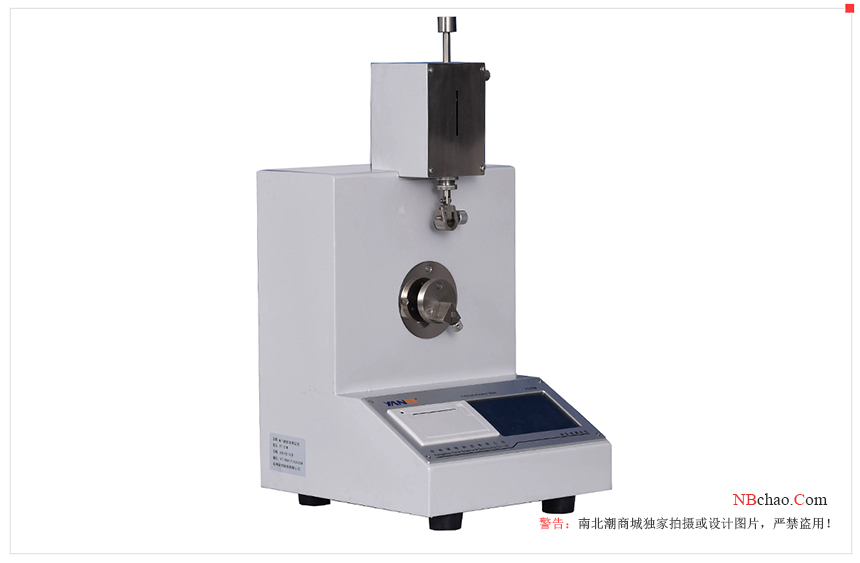

Bursting strength is also called the top force, that is, the maximum pressure that the paper can withstand a uniform increase, and the unit is kg/cm2. The average length and binding force of fibers are the main factors affecting the bursting strength.

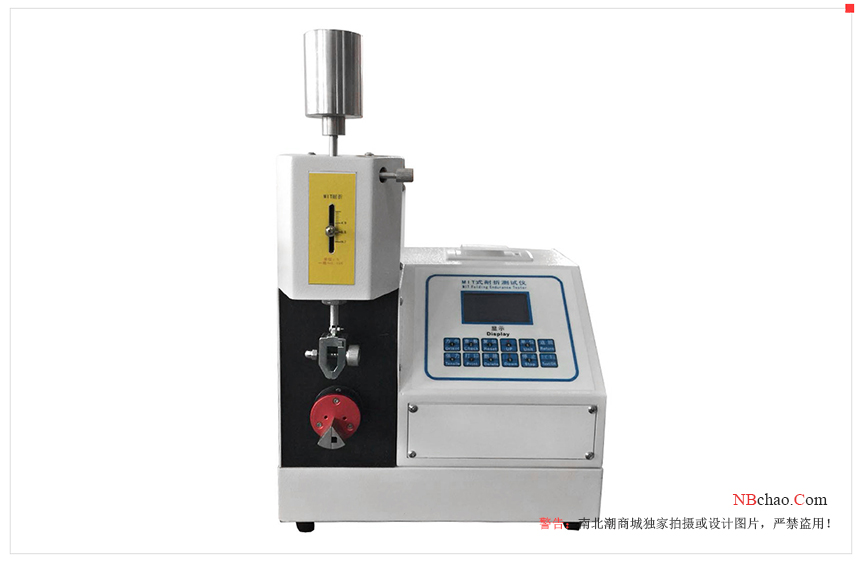

The folding endurance indicates the paper's ability to withstand folding. It is the number of times the paper is folded back and forth at 180 degrees under a certain tension until the paper breaks. So his unit is (double-fold) times. The folding endurance of poor-quality paper is only about 20 times, and the folding endurance of high-quality paper (such as banknote paper) can reach more than 1,000 times. The folding endurance is mainly determined by the strength of the fiber itself. Of course, the process conditions of papermaking, the interweaving of fibers, the size of the bonding area, etc. also have a certain relationship.

Tear refers to the ability of paper to resist shear (shear) force. The average length of the fiber is related to the tearing degree of the paper, and its unit is grams.

The so-called "paper defect" in appearance refers to some defects of paper that are very visible to human flesh, such as dust, spots, light spots and curtains (the paper is uneven in thickness, and when viewed against the light, the small ones are called light spots. The big ones are called through curtains), holes and holes, folds, cracks, wrinkles, hard blocks, streaks and so on.

- 1Paper tearing determination - Alimendorf method and instrument operation guide

- 2Folding Tester - paper folding performance test

- 3Tear Tester of paper strength

- 4Talking about the application of folding resistance Tester in metal foil

- 5Plastic film folding resistance testing by folding resistance Tester

- 6How is the folding resistance Tester used for the detection of tissue paper?

- 7Analysis on the Application of Folding Tester in Cardboard

- 8What is the folding resistance of paper and cardboard?

- 9Test method for tensile strength of fabrics