What is the difference between an RDS wire rod applicator and an OSP coating rod?

The wire rod coater is used for the laboratory to make coating proofing. The American RDS and Japan OSP are two popular wire rod coater brands in CHINA. The two brands can be used as substitutes for routine experimental requirements. . But when users of Beichao choose, they will hesitate which brand should I choose. In fact, they are all similar, and you should choose according to the actual experimental requirements and personal preferences.

This article compares the differences between RDS and OSP from the dimensions of coating thickness selection, coating width, coating process, and price, and provides a reference for users who purchase wire Bar Coaters.

Variation in film thickness

The choice of wire Bar Coater is first to determine the thickness requirements of the experimental coating film. Only by determining the thickness can the specific coating rod number be determined.

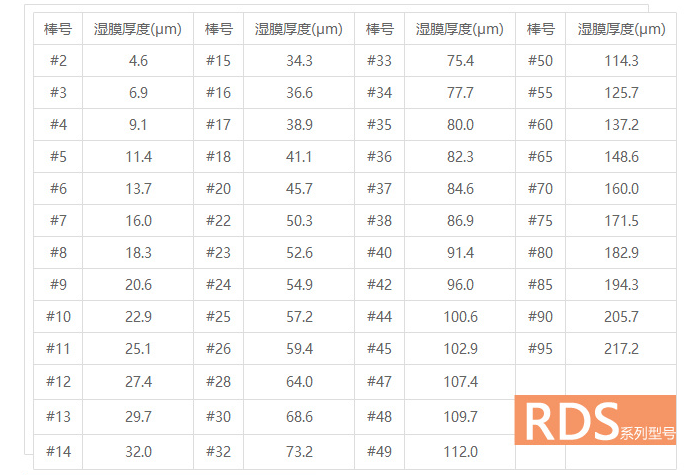

RDS wire Bar Coaters are available in rod sizes 2 through 95, and film thicknesses range from 4.6 µm to 217.2 µm. Among them, the smallest rod number of the wire-wound rod is No. 3 rod, the thickness of the coating film is 6.9 microns, the largest rod number is No. 80, and the coating film thickness is 182.9 microns. The rod size of the formed wire rod ranges from No. 2 to No. 95, and the thickness of the coating film is as small as 4.6 μm , reaching 217.2 μm.

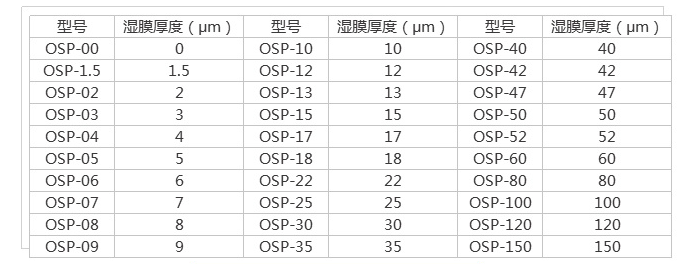

OSP coating rods are all extruded, and the thickness of the coating film is 0~150 microns. The wet film thickness corresponding to the number of OSP is a few microns. For example, OSP-1.5 has a film thickness of 1.5 μm. OSP can achieve a thinner coating thickness of 1.5 microns, but the larger coating thickness can only be 150 microns.

Coating width

American RDS wire bar applicators are all 40cm long, and the coating width is 30cm. Both ends of the bar have a 5cm hand grip part, and no supporting handle is needed.

Japanese OSP has three different coating widths: 6cm, 25cm, and 30cm, of which 6cm is its characteristic, and can be as long as a finger, saving the cost of experimental samples. The 25cm and 6cm wire rods have the effective coating width for the whole rod, so they can be equipped with a handle for scraping coating, which makes the operation easier.

Coating process

There are two common coating processes for wire rod coaters: wire-wound type and extrusion type. The wire-wound type is more in line with the traditional mayer rod coating principle, and steel wires of different diameters are wound on the steel rod. The extrusion type uses cold extrusion technology to extrude continuous grooves of different sizes on the steel rod to control the thickness of the coating film.

There are two different common processes for RDS in the United States, both wire winding and extrusion. However, the Japanese OSP wire Bar Coater has only one type of extrusion process. Because of its process principle, there is no broken wire, and it is relatively convenient to clean. The RDS wire rod has a history of hundreds of years in the industry, so its winding wire is very firm, and the situation of wire breakage is very rare, unless the small rod is not handled with care and is bumped, after all, the wire diameter is very thin .

Coating Rod Diameter

American RDS wire rods have three diameters: 1/4'' (6.35mm), 1/2'' (12.7mm), and 3/8'' (9.5mm), among which the 3/8 diameter is the more popular model. It is more in line with the gripping habits of domestic users. The Japanese OSP rod diameter is only 10mm.

Price

The prices of the three different diameters of RDS in the United States are different, and you can buy more than 400 to 500 for a single stick, and you can get a discount if you buy more; while the prices of different lengths of OSP in Japan are different, from 200 to 500.

The above is the comparison of the differences between the American RDS wire rod coater and the Japanese OSP in different dimensions, hoping to provide you with a reference.

- 1Application of Mayer Rods in protective coating prepative

- 2Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 3Application of Mayer Rods in composite coating prepative

- 4Several Common Experimental Spreader Methods and Their Applications

- 5Application of Mayer Rods in Water-based ink Moulding

- 6Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

- 7The experimental case of OSP Mayer Rods at inks Moulding [with video]

- 8Why Do Film Applicators Need to Change Their Wires Regularly?

- 9Mayer-Rod (Mayer Rods) Preparative 2D Copper Nanosheets