Appreciation of the details of the coating film of the American RDS wire rod applicator

American RDS wire rod coater is an imported experimental coating wire rod. It has 90+ years of historical experience. It has fine workmanship and uniform coating film. NBCHAO Mall, as the general agent of RDS in CHINA, brings together a full range of RDS wire Bar Coaters. RDS wire rods are very popular in various domestic sub-sectors, and many scholars have mentioned them in papers. It has two processes of wire winding and extrusion, and is divided into a variety of series with different diameters to meet more user application needs.

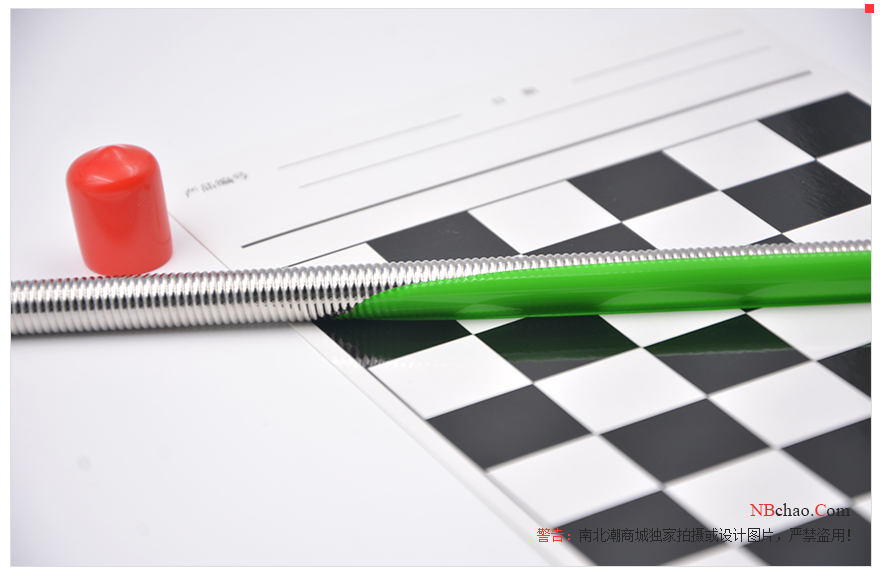

In order to more comprehensively show users the characteristics of each dimension of RDS wire rods, Beichao has photographed a lot of RDS coating wire rods, in terms of appearance, details, and coating effects. This article is mainly to share some detailed pictures of RDS wire Bar Coater coating film appreciation.

The above pictures are a series of wire winding process diagrams of RDS wire Bar Coater. The winding is 303 wear-resistant stainless steel, and from the workmanship of the interface, the winding wire is very firm. It has avoided the worry of easy wire breakage of the wire-wound wire rod, and it is true that the RDS squeegee basically has no broken wire under non-artificial conditions.

In addition to the wire-wound type, RDS is also producing the formed wire rod in the follow-up, which has the advantage of being easy to clean. Its coating effect is the same as that of the wire-wound type. Compared with the structural principle, the coating amount will be slightly more than that of the wire-wound type. This is a difference between the extrusion type and the wire-wound type.

- 1Application of Mayer Rods in protective coating prepative

- 2Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 3Application of Mayer Rods in composite coating prepative

- 4Several Common Experimental Spreader Methods and Their Applications

- 5Application of Mayer Rods in Water-based ink Moulding

- 6Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

- 7The experimental case of OSP Mayer Rods at inks Moulding [with video]

- 8Why Do Film Applicators Need to Change Their Wires Regularly?

- 9Mayer-Rod (Mayer Rods) Preparative 2D Copper Nanosheets