How to measure the gloss of different products?

Gloss is the main attribute of the product, giving the product a glossy and shiny metallic appearance. Measuring the glossiness of a product is the primary sense humans use to inspect objects. The procedure plays an important role in measuring gloss and helps to measure the psychological impact of products on consumers and also influences their purchasing behavior.

How does gloss affect customer buying behavior?

The gloss of a product is mainly influenced by different factors, for example, the smoothness achievable during polishing, the quality and type of coating applied to the material, etc. Manufacturers in the automotive industry especially design their products with maximum reflectivity and gloss. The exterior quickly catches the attention of customers. Apart from the automotive industry, black satin furniture, reflective body panels, glossy magazine covers, glossy gadgets grab the attention of buyers and play an important role in influencing customers' purchasing decisions. Therefore, it is very important for manufacturers in every industry to keep the gloss of the product constant on each product or from batch to batch.

The glossiness of a material can also help buyers gauge surface quality, with a drop of water on a glass or glossy coated product indicating a defect in the product. Manufacturers in different industries therefore place particular emphasis on the gloss of their products, whether it is automotive, printed materials, food, pharmaceuticals or consumer electronics.

How to measure the gloss of a product?

The glossiness of any product can be measured as the actual percentage of surface gloss when a standard amount of light is reflected on a specific area and reflected back. The angle of light and the method by which reflectance can be measured is determined by the surface of the material. This is a suitable method for determining surface gloss.

Different types of product gloss

Constant Gloss – Also known as Haze or Gloss. This type of gloss is observed from observation and incidence.

Specular Gloss – Specular gloss is the proportion of light that is reflected to the other side of a surface at a specified angle.

Lack of Halo – Measured by measuring the haze or milky appearance next to reflected light.

Sharpness of the image - it is the sharpness of the reflected light.

Lack of Surface Texture Gloss – Perceived surface smoothness and uniformity.

Gloss Tester

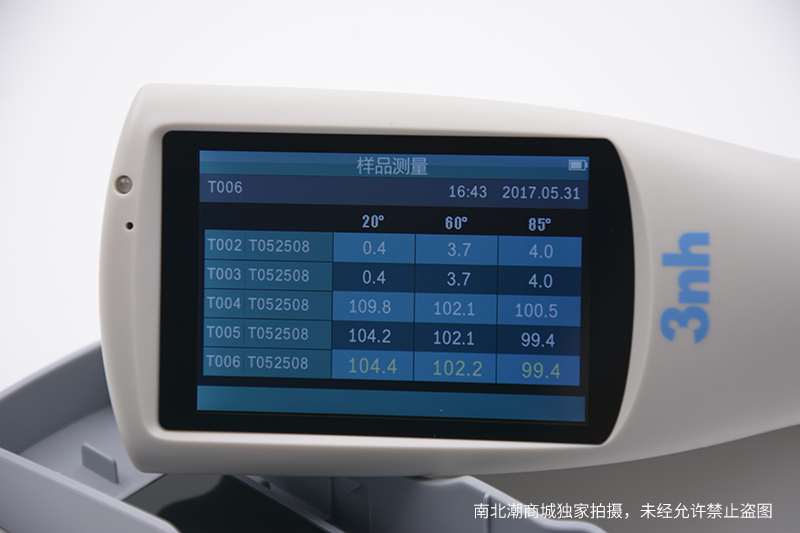

3nh/3nh HG268 three-angle gloss meter is a gloss meter with three measurement angles of 20°, 60°, and 85°. It has a large color display screen and can choose a variety of angles for measurement to meet different gloss measurements. The needs of the occasion. HG268 three-angle gloss meter is operated by buttons, adopts Chinese and English bilingual operating languages, and has a menu-based operation interface, which is easy and convenient to operate. In addition, HG268 three-angle gloss meter is equipped with computer software to operate and manage the data.

Gloss meter technical indicators

Measuring range of different angles: 20 degrees: 0 to 2000GU; 60 degrees: 600-1000GU; 85 degrees: 0 to 160GU .

Partition Value – 0.1GU

Measurements can also be taken from different geometries.

Chromaticity: Under CIE C light source, CIE 1931 (2°) photometric response

Communication port: USB/RS-232

Touch screen display: TFT true color 3.5inch display

The main expertise of gloss meter

The instrument is compact, accurate, portable and sensitive.

This tool is very effective in measuring the strength of plastics, hardware, automobiles and more.

Easy to operate and user friendly equipment.

The measurement standards comply with national and international standards for gloss measurement.

Standard accessories supplied with the instrument include USB cable, power adapter, software CD (except for base models), user manual and calibration board.

A tool for automatic calibration of data.

The auto-save function enables the test data to be saved automatically.

Software-based test result output.

Can measure simultaneously from three standard angles (20°, 60° and 85°).

- 1Principle and Application of Glossiness Tester

- 2Working Principle and Application of Metal Gloss Meter

- 3Basic principle and application analysis of insulating paint gloss Detector

- 4Working principle and application analysis of film Glossmeter

- 5Principle and application analysis of microporous gloss meter

- 6 FZ/T 01097 Analysis of fabric gloss test method

- 7Evaluation and Application of Optical Properties of Powder coatings

- 8Coating coatings - Determination of surface gloss and Gloss meter

- 9The Importance and Method of Gloss Measurement of Paint Film