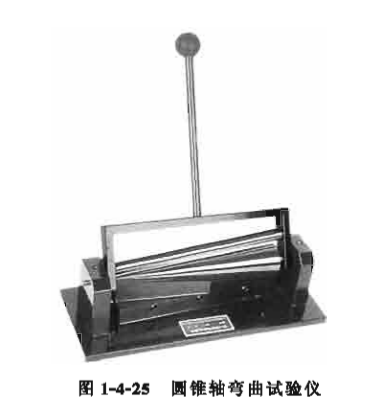

Detection method of conical shaft bending Tester

1. Scope and description

This method is applicable to the evaluation of the resistance to cracking or peeling from metal substrates when the coatings of paints, varnishes and related products are bent around a tapered axis under standard conditions .

2. Instruments and Materials

(1) The conical shaft bending Tester is also called the conical bending Tester, as shown in Figure 1-4-25. The central axis is a cone, the diameter of the small end is 3.2mm, the diameter of the large end is 38mm, and the length of the whole cone is 203mm. The tapered shaft is mounted horizontally on a base, and there is an operating rod with a pull rod to bend the test plate around the tapered shaft, and a device for clamping the test plate.

(2) Test board

8mm。 Steel, tin plate or soft aluminum plate, the size is 100mmX 180mm, and its maximum thickness is 0. 8mm.

3. Measurement method

(1) Cut through the test plate in parallel at a distance of 20 mm from the short side of the test plate. Insert the test panel with the painted side facing the tie rod so that one of its short sides is in contact with the small end of the shaft.

(2) After clamping the test plate, use the pull rod to bend the test plate evenly and smoothly, so that it can rotate 180° around the axis within 2~3s. Check immediately for cracking .

Note, a piece of paper can be placed on the coating surface between the test plate and the tie rod to prevent the coating film from being damaged due to the rubbing of the tie rod during the bending operation .

4. Result presentation

Check the test panel visually or with an agreed 10x magnifying glass, and measure the distance from the small end of the shaft to the cracking area along the test panel, in cm.

Measure three times, take the average value, and the result is accurate to centimeters (unit).

5. Reference standard

National standard GB/T 11185 "Bending Test of Paint Film (Conical Shaft)".