Differences in Viscosity of Different Standard Flow Cups

The Flow Cup viscometers used in various countries in the world have different names, and are divided into different models according to the size of the outflow aperture. The shape of various Viscosity Cups is roughly the same, but the structural size is slightly different. CHINA's general Tu-1 viscometer and Tu-4 viscometer (GB/T 1723-1993) are equivalent to the ISO Flow Cup (GB/T 6753.4-1998); the United States uses the Ford (Ford) cup [ASTM D 1200- -1994 (1999)]; Germany uses the DIN Viscosity Cup (DIN 53211- 1987). They are all divided into different models according to the aperture size, such as ISO cups with 3#, 4# and 6#, Ford cups with 2#, 3# and 4#, DIN cups with 2#, 3#, 4# #, 6# and 8# five kinds. Each type of Viscosity Cup has its suitable measurement range. CHINA's Tu-1 viscometer is suitable for measuring coatings with an outflow time greater than 20s, Tu-4 viscometer is suitable for measuring coatings with an outflow time of 20~100s, ISO and Ford The cup is specified as 30~90s. If it is lower or higher than the outflow time range, the accuracy of the measured data will be poor. The outflow time can be converted into kinematic viscosity , but the conversion formulas of various Viscosity Cups are different. Viscosity cups with the same pore size have different structural dimensions, and the kinematic viscosity values converted from the same outflow time are different, that is, the outflow time of samples with the same kinematic viscosity value in different types of Viscosity Cups is very different. CHINA's Tu-4 viscometer is close to the Ford 4# cup, but it is very different from the ISO4# cup. If the measured outflow time is 65s, the conversion value of kinematic viscosity with Tu-4 viscometer is 250mm2/s, and the Ford 4# cup is 232mm2/s, which are relatively close, while the ISO 4# cup is 85mm2/s. For a coating sample with a kinematic viscosity of 300mm2/s, use Tu-4The outflow time measured by the meter is 80s, 82s with Ford 4# cup, 67s with DIN 4# cup, and over 100s with ISO 4# cup. 6mm), the measured outflow time is 44s.

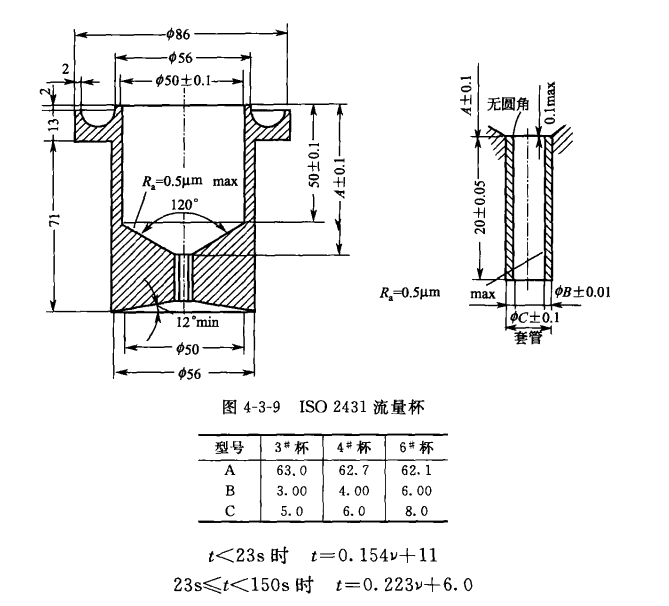

Therefore, when using a Flow Cup to measure viscosity, it is necessary to select a suitable type of viscometer according to the viscosity of the sample. The measured outflow time is preferably in the middle of the specified range, and indicate which type of viscometer is used for the measurement. This should be paid attention to when formulating the technical indicators of coating products, and choose the appropriate viscosity measurement method. Figure 4-3-8 and Figure 4-3-9 list the dimensions of Tu-4 viscometer and ISO Flow Cup respectively . Specifications for Ford cups are found in ASTM D 1200- 1994 (1999). The suitable measurement range of the Tu-4 viscometer is the outflow time of 20~100s, and it is suitable for the measurement of coatings with a kinematic viscosity of 60~360mm2/s. The following formula can convert the outflow time s of the sample measured by Tu-4 viscometer into the kinematic viscosity value mm2/s.

In the formula

t well out of time, s;

Kinematic viscosity, mm2/s.

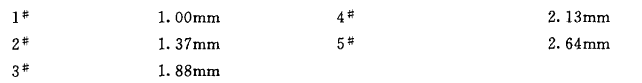

In addition, there is an outflow viscometer suitable for construction sites, called Zahn cup, as shown in Figure 4-3-10. It is a cylindrical, spherical bottom, lightweight Viscosity Cup with a longer handle. Its volume is about 44cm3. According to the size of the small hole at the bottom , it is divided into 5 models and combined into a set. The radii of the holes for each model are:

The suitable measurement range is 30~90s at the outflow time. Each model measures products , and the measurement range is 30~2000mm2/s. This kind of viscometer is characterized by simplicity, convenient operation and suitable for on-site use.

- 1Liquid viscosity measurement and application

- 2Measuring method of coating viscosity

- 3Viscosity: Microscopic forces inside liquids shape macroscopic properties

- 4Thermostatic bath working principle and its application in viscosity measurement

- 5Rotational viscometer measurement of molasses viscosity

- 6Chocolate viscosity measurement with Rotational Viscometer

- 7Polymer Solution Viscosity Testing Solutions

- 8How to test the viscosity of lithium battery stirring slurry?

- 9How is the viscosity of the paste tested?