Film Appliances: Scraper Mayer Rods Automatic Film Applicator

In order to make the results of film testing accurate and reliable, it is necessary to prepare standard films that meet the requirements. According to the provisions of the product standard, the preparation of uniform films with specified Film thickness on the specified substrate is the basis of film testing. The obtained film must truly reflect the essence of the film, even if there are defects, it must be reflected, but the essence of the film cannot be changed due to external reasons, such as the preparation environment.

To make a uniform film template, attention should be paid to the selection and treatment of the baseplate, and the preparation method and conditions. The material of the baseplate is selected according to the product standard, and the surface treatment should meet the requirements. When preparing the film, the Coating viscosity, preparation method, environment temperature and humidity, drying conditions and time must strictly abide by the specified requirements. All countries have formulated standard methods for film preparation. My country's national standard GB/T 1727- -1992 "Film-General Preparation Method" stipulates the materials for preparing general films, the surface treatment of baseplates, the method of making plates, the drying and state adjustment of films, Constant temperature and humidity conditions and film thickness, etc. The plate making methods are listed as brush coating method, lame plating method, dipping method, scratch coating method, uniform film preparation method and pouring method. Among them, film Applicators (Scrapers and Mayer Rods) are commonly used preparation instruments.

The instrument used in the scraper method is called a doctorblade or a Film Applicator, as shown in Figure 4-3-26. During operation, pour the sample on the baseplate and flatten the sample with a scraper. Since the scraper blade has a certain gap with the plane, a wet film thickness can be obtained

Film. According to the needs of the test, the gap between the blade and the plane can be adjusted to obtain films of various Film thicknesses. Generally speaking, the thickness of wet film is only half of the gap spacing between the scraper and the baseplate, and the success of the scraping method depends on the flatness of the baseplate and the mass of the scraper, otherwise corrugated films or Miscellaneous irregularities will occur.

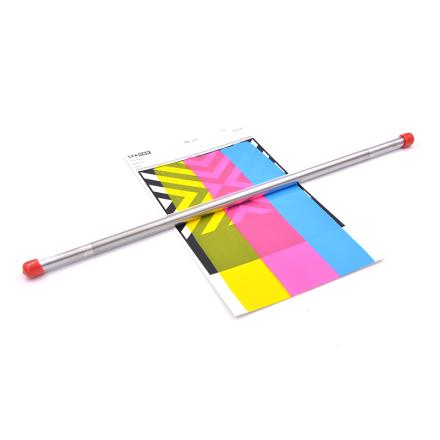

Later, the wire rod scraper was developed. This instrument comes in two forms. One is a metal rod, on which a metal wire is tightly wrapped. Coating is applied to the sample through the space formed by the metal wire. The thicker the metal wire, the larger the space and the thicker the film. This scraper is especially suitable for flexible substrates such as paper or thin metal plates. Another form is a nylon rod, cut directly into a screw pattern on the rod car, a black rod can be used for light Paints, and a white rod can be used for dark paint. This contrasting Color helps to clean the scraper.

In order to make the operation of the scraper smooth and uniform to eliminate human operation errors, an automatic Film Applicator driven by a motor is now developed to make the scraped film more uniform. One of them is shown in Figure 4-3-27, see ASTM D 823-1995.

Sometimes free films that are not attached to the substrate or on the substrate are used for experimental research and testing of certain film performance. The preparation method of free films used to use the tin amalgam method, and the surface of the tin-plated steel plate was painted by the lame plating method or the dipping method. After curing, one end of the painted steel plate was placed in a wide-mouth bottle containing mercury. Mercury penetrates under the coating of the steel plate and tin undergoes a tin amalgam reaction. Finally, the film can completely fall off the steel plate. This method is harmful to the operator's body and has been banned in some countries. Now most of them can be prepared from Glass plates coated with mold release agent, and also prepared with release paper. The coating can be used with Mayer Rods Spreader, and a free film with uniform thickness can be obtained.

- 1Application of Mayer Rods in protective coating prepative

- 2How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 3NVP anode film FAQ and solution

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Scraping machine selection case: film substrate large size high accuracy scraping solution

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films