Principles of steps for the determination of thickness, tightness and bulk of paper and paperboard

Thickness affects many properties of paper and board. It is an important condition for the use of printing paper, capacitor paper, impregnated paper and other paper. Therefore, it is required that the thickness of each piece of paper of a batch of products should be consistent, and the thickness of different parts of the same piece of paper should also be consistent, so as to ensure the use effect.

1 definition

(1) single layer thickness

The vertical distance between two sides of paper, cardboard or other material is measured by applying a static load using standard test methods.

(2) Layer thickness

The thickness of a single-ply paper is calculated by applying a static negative lean to measure the thickness of several overlapping paper sheets using standard experimental methods.

(3) Single layer tightness

Quality per unit volume of paper and board, expressed in g/cm² , calculated from quantitative, single-ply thickness.

(4) Lamination tightness

The mass of paper and board per unit volume, expressed in g/cm², calculated from the basis weight and ply thickness.

2 principle

Under the specified static load, use a high-precision Thickness Gauge to measure the thickness of a single sheet or a stack of sheets, and express it as a single layer thickness or a laminated thickness according to the experimental requirements.

3 instruments

(1) Thickness measuring instrument

There are two forms of electric and manual,

(2) Thickness block gauge

The corresponding values are 10%, 30%, 50%, 70%, and 90% of the full range of the thickness measuring instrument, and each block gauge is accurate to 1 μm.

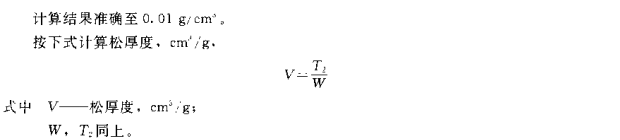

4 Instrument structure

The structure of the thickness measuring instrument is shown in Figure] 8-1, mainly including four parts.

(1) The measuring mechanism is composed of a weight, a measuring head and an anvil. The specified measuring area is (2±0.05 ) cm2, and the measuring pressure is (100±10) kfa .

(2) The indicating mechanism is a standard dial indicator, which is used to record the thickness value. The accuracy of the scale value is within 0.005 mm.

(3) The lifting mechanism is used to lift the measuring head to take and place the sample.

(4) The seat body is the whole instrument formed by connecting the base with the above-mentioned three-part mechanism.

5 Calibration of the instrument

(1) Flatness of the pressure measuring surface

Lift the measuring head so that the two measuring surfaces are separated, and carefully wipe the surface of the pressure measuring surface. And look at the gap against bright light, when observing the measurement surface from two perpendicular directions. The gap should be fairly even.

(2) Parallelism of the measuring surface

①Take a thickness block gauge and put it between the two measuring surfaces and make it as close to the side edge as possible, then put the gauge surface close to the block gauge and record the reading of the Thickness Gauge.

② Put the same piece of gauge between the measuring surfaces, try to make it as close as possible to the edge exactly opposite to ①, then put the measuring surface close to the block gauge, and then record the reading of the Thickness Gauge.

③Repeat the above operation steps on the diameter edge passing through the points ① and ② vertically.

④Repeat the above operation steps one by one for the remaining thickness block gauges.

Calculate and measure the parallelism error of each gauge according to the following formula

(3) Pressure applied to the measuring surface

Any suitable method for verifying the accuracy and uniformity of applied pressure may be used.

6 Experimental steps

(1) Sampling is carried out according to the standard Huai method, and the temperature and humidity are treated.

(2) Preparation of samples

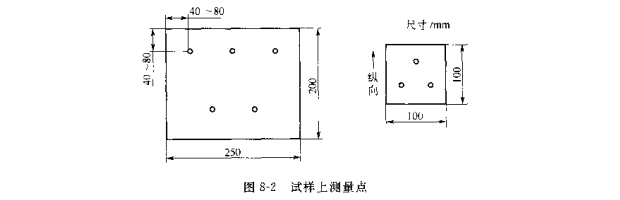

①Laminated thickness sample. Randomly select a sample from the sample according to the regulations, preferably cut into a size of 200 mm × 250 mm, the side of 200 mm should be along the longitudinal direction of the paper (see Figure 8-2), if not possible, prepare a smaller sample , but not less than 150 mm×150 nm. To form a sample by stacking 10 layers of paper, it is necessary to ensure that the number of layers of each sample is the same and that all the sheets are stacked in the same direction, and the sheets should be independent of each other. For example: It is not allowed to stack the sheets of paper in the sample to form two or more pages . Prepare at least four stacks of specimens.

②Single layer thickness sample. Randomly select a sample from the sample according to the regulations, and cut it into a sample with a size of not less than 60 mm×60 mm, but do not make the sample too large, so that when the test is carried out. The sample hangs on the anvil to affect the reading, so the cardboard sample is not allowed to exceed 100 mm x 100 mm. The size of this sample can usually be used to measure the paper.

(3) Determination of thickness Place the Thickness Gauge on a level surface without vibration, and put the sample between the opened measuring surfaces. Place the specimen on the pressure-bearing surface and carefully move the other measuring surface gently towards the anvil at a speed of less than 3 mm/s, thereby avoiding any impact. Read the reading of the Thickness Gauge immediately after the indicated value is stable, usually within 2~5s, but read it before the paper is "sinked", and avoid artificially exerting any pressure on the sample or Thickness Gauge during measurement.

For the layered thickness, measure the thickness of the sample at five specified points on each sample as shown in Figure 8-2. The measurement point is 40~80 mm away from one side of the sample, and then distribute across the sample along both sides. Measuring point. At least four samples are measured.

For single layer thickness, one measurement is made for each specimen. The measuring point is less than 20mm away from any side of the sample

7 Presentation of results

(1) Layer thickness

Calculate the average of the readings (not less than 20) and divide by the number of sheets constituting each sample. The resulting value is the laminate thickness of the single-ply sheet, expressed in microns to three significant figures. Record the maximum and minimum values of the stack thickness: calculate the standard deviation of the stack thickness; calculate the confidence interval at the 95% confidence level.

(2) The average value of the single-layer thickness calculation readings (not less than 20) is the average thickness of the single-layer paper sheet, expressed in microns to three significant figures. Record the maximum and minimum values of the monolayer thickness: calculate the standard deviation of the monolayer thickness; calculate the confidence interval at the 95% confidence level.

(3) Lamination tightness and bulk thickness Calculate the lamination tightness according to the following formula, g/cm²,