Shoeber method - determination of folding resistance of paper

1 definition

(1) Folding endurance

Under a certain tension, the paper can withstand the number of reciprocating 180° folds.

(2) double fold times

The sample is first folded backwards, and then folded forwards on the same fold. One back and forth is a double fold, which describes the folding resistance of the paper.

2 instruments

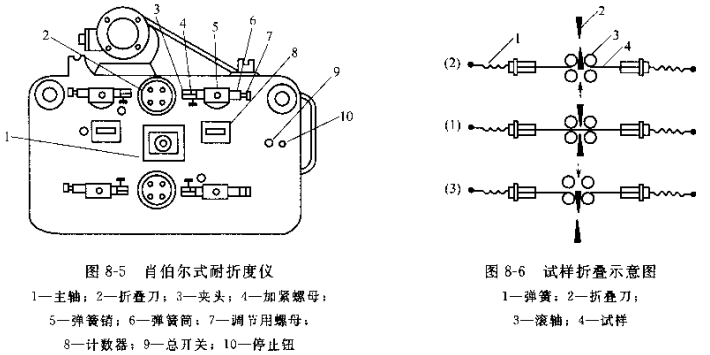

The structure of the Schober folding Tester is shown in Figure 8-5, which mainly includes the following two parts.

(1) transmission part

The motor drives the two curved arms through the belt pulley to make the folding knife move back and forth, and the curved arms control the movement of the counter. The lower protection switch can stop the motor.

(2) Test part

Including a pair of spring barrel, collet, folding knife and counter. One end of the spring in the spring container is fixed on the spring, and one end is connected with the collet, and the spring container can move on the base. The tension spring can apply a certain tension to the sample, lift the spring pin, the spring releases the tension and returns to its original position. The center of the folding head is equipped with two pairs of rollers with a pair of folding knives between them. The paper strip is perpendicular to it between the folding knives. During the test, the vertical reciprocating motion between the rollers and the folding knife is performed (Figure 8-6). The counter will display the number of folds. In order to control the counter to stop when the paper strip breaks, A wrench is installed under the spring to operate and stop the counter.

3 working principle

The paper strip is subjected to longitudinal stress in the standard state, folded backwards and forwards, until it breaks.

4 instruments

1. Device for folding paper

There are two pairs of horizontally opposed chucks for clamping the sample, 4 rollers and a reciprocating blade with a narrow slot. The distance between the two clamps is 90 mm, and the clamp is connected to the tension spring, which can clamp the sample in the vertical plane under a certain tension. The bottom of the chuck is supported by a roller. When the chuck is in contact with the supporting roller, the chuck moves freely in the air. The sample is folded back and forth by the slit blade until it breaks and stops moving.

(1) Fold the J piece, the thickness of the folding blade is 0.5rmIm, the width of the knife slit is 0.5nm, and the contact between the vertical seam edge and the sample is semi-circular with a radius of 0.25mm.

(2) Hemming rollers 4 hemming rollers, each with a diameter of 6 mm and a length of 18 mm, the distance between the folding blade and each hemming roller on both sides is 0.3 mm, two vertical lines The distance between the two pairs of rollers is 0.5 mm.

(3) Spring tension, when the sample is clamped in the clamp, the spring tube is pulled apart, and each spring is applied to the sample. The initial tension is (7.55±0.10) N [(770±10)g], when folded When the blade moves to the limit position and the sample is at the maximum bending, the tension applied by each spring is (9.81±0.10)N_(1000±10)g].

(4) Folding speed, turn on the instrument, make a simple harmonious movement of the folding blade back and forth, the front and rear strokes are 10 mm each (20 mm in total), and the number of double foldings per minute is (110±10) times.

2. Instrument maintenance and calibration

①Except for chucks and tension springs, all moving parts must be kept lubricated. Be careful to apply light machine oil (horological oil) to lubricate and avoid staining the specimen. All rollers should be able to rotate freely, and the whole machine should be kept free of dust and paper wool.

②The splint surface of the chuck should be completely in contact with the sample, and the sample should be clamped. After the sample is clamped into the collet and the spring tension is applied, the sample should remain straight. If the sample is bent or wrinkled, it means that the clamp is not properly clamped, the tension is uneven or there is slippage. Check whether the collets are parallel, whether there are pieces of paper in the jaws, how the splint surface is in contact with the sample, etc.

③The spring tension should be calibrated regularly, remove the collets and springs from the instrument base, fix the collets vertically on the frame with a right-angle frame, and calibrate the collets one by one. Add a weight of 7.55 .V (770 g) (including the mass of the chuck itself), the distance that the clip protrudes is 5 mm, that is, the first engraved line, plus a weight of 9.81 N (1000g) (including the weight of the chuck The quality of itself), the distance that the clip protrudes is 13 mm, which is the second engraved line. If it does not meet the requirements, adjust the knurled nut at the end of the spring until it meets the requirements.

④ Check the 4 hemming rollers. They shall be exactly parallel to each other and at right angles to the direction of specimen motion, and both shall be free to rotate. The two sides of the folding seam should be parallel to each other and parallel to the hemming roller, and the surface needs to be smooth and free of defects.

⑤The folding speed may be lost at any time due to the belt drive, so it should be checked at any time. Check the instrument with a stopwatch to see if it is (110±10) double fold times per minute.

5 Sample collection and preparation

Cut at least 10 samples from the longitudinal and transverse directions of the sample, the length of the sample is 100 mrn, the width is (15±0.1) mn, and it is prepared under the same standard atmospheric conditions as when processing the sample.

The sample taken must not have paper defects such as folds, wrinkles, stains, etc. There should be no watermarks on the folded part of the sample, and the two long sides of the sample should be cut and parallel. Do not touch any part of the specimen exposed between the two grips with your hands.

6 test steps

The test is carried out under the same standard atmospheric conditions as when the samples were processed.

Tighten the sample that has been prepared and processed in parallel between the two clamps of the measuring instrument, pull the spring bar, apply an initial tension of (7.55±0.10) N[(770±10)g] to the sample, and count Return the instrument to zero, start the folding blade of the instrument to the farthest position, the maximum tension is (9.81±0.10)N[(1000±10)g], fold back and forth until it breaks, the instrument automatically stops recording readings, and remove the broken test piece In this way, the instrument recovers and prepares for the next test.

If the specimen does not break at the fold line, the test shall be discarded. If the sample has delamination during the folding process, it should be explained in the report.

Note: During the folding process, due to the friction and heat generated by the motor and the sliding folding sheet, the sample strip will be partially brittle and the folding resistance will be reduced. Therefore, the motor and the folding head should have effective ventilation. After the instrument runs continuously for th, The temperature in the area of the anti-folding instrument shall not be higher than the average temperature of the laboratory where the instrument is operated by more than 1 °C.

7 test report

The measurement results are expressed as the arithmetic mean of all measured values in the vertical and horizontal directions, and the maximum and minimum values are reported. Calculated results are rounded to integers.

- 1Folding Tester - paper folding performance test

- 2Talking about the application of folding resistance Tester in metal foil

- 3Plastic film folding resistance testing by folding resistance Tester

- 4How is the folding resistance Tester used for the detection of tissue paper?

- 5Analysis on the Application of Folding Tester in Cardboard

- 6What is the folding resistance of paper and cardboard?

- 7What are the factors that affect folding endurance?

- 8Test method and principle of corrugated cardboard folding resistance meter

- 9FRANK horizontal refractometer test method