Paper and board - Determination of folding strength - MIT folding method

1 definition

Folding endurance refers to the number of times that paper or cardboard can withstand reciprocating 135° double folds under a certain tension, expressed in terms of double fold times of reciprocating folding.

2 working principle

Put the sample between the grippers, under a certain tension, through the left and right swing of the lower gripper, make the sample in . Make reciprocating folding movement within a fixed angle. As the number of folds increases. The strength of the sample gradually decreases until it cannot withstand the tension of the spring, and the number of folds when it breaks is the folding resistance of the sample.

3 instruments

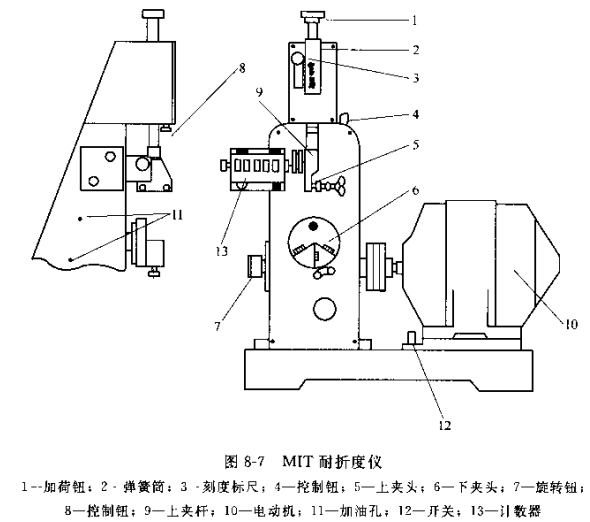

The MIT folding Tester (see Figure 8-7) includes the following parts.

(1) The transmission part, the motor is decelerated to 175 times/min through a round belt and a gear, and then through the eccentric slider mechanism and the racks installed on both sides of the slider, it meshes with the pinion on the swing shaft. Make the lower chuck swing left and right.

(2) Chuck part

Includes upper and lower chucks. The width of the collet is (19 ± 1) mm, and the arc radius of the folding mouth is (0.38 ± 0.02) mm. Upper. The chuck clamps the sample with a screw, and applies a certain tension to the sample through a spring, and its size can be adjusted with a knob. The lower chuck adopts a wedge structure to clamp the sample, and the jaw is also a folding mouth. During the measurement, the sample is reciprocally folded at an angle of 135° by the left and right swing of the lower chuck.

(3) Counter

The electromagnetic counter is adopted, and its switch is controlled by the action of the slide plate and the upper chuck. Once it is folded, the circuit is connected once, and then it is counted once. When the sample breaks, the spring lifts the upper chuck, cuts off the circuit through the micro switch, and stops counting.

(4) Control part

It is a motor linkage device, when the sample breaks, the motor stops automatically and the counter stops counting.

4 Calibration of the instrument

(1) Calibration of spring tension Rotate the adjusting knob to move the pointer to two divisions lower than the scale of the load. Then put the special test weight on the top of the support cap, loosen the adjustment button, observe whether the pointer on the dial is consistent with the quality of the weight, and check the three points of 0.5 kg, 1.0 kg, and 1.5 kg. If there is any deviation, the pointer position should be moved to make the exact value at 1.0 kg, and the difference between 0.5 kg and 1.5 kg should be recorded for correction during use.

(2) Calibration of tension changes in the folding process Put a paper strip of appropriate thickness and strength on the chuck, apply a tension of 1 kg, and slowly rotate the folding head for a circle, that is, a round trip, as in the case of measuring the folding endurance. Observe the spring displacement change, accurate to 0. 1 mn, the force indicated by the displacement change is less than 343 mN (35 g).

5 Operation steps and result calculation

① Sampling shall be carried out according to the standard method, and the sample shall be subjected to temperature and humidity treatment under standard atmospheric conditions.

② Sample cutting. Cut (15±0.1) mm, length of not less than 140 mm samples, the vertical and horizontal directions are not less than 10. Determine the tension of the spring according to the sample. A spring tension of 1.0 kg (9.81N) is used for routine tests, and a spring tension of 0.3 kg (4.91 N) or 1.5 kg (14.72 N) can also be used .

③Clamp the sample vertically between the two clamps of the folding head, loosen the spring fixing screw, and observe whether the spring tension pointer points to the desired position, and readjust if there is a position difference. Start the instrument and start folding back and forth until the sample breaks. It should be noted that half of the sample is folded to the front first, and half of the sample is folded to the reverse. Read the indication value of the counter at the time of breaking. The counter is cleared and the next test is carried out.

④Repeat the above test procedure, and test 10 samples vertically and horizontally.

⑤ The results are expressed as the arithmetic mean of all measured values in the vertical and horizontal directions, and the maximum and minimum values are reported.

- 1Folding Tester - paper folding performance test

- 2Talking about the application of folding resistance Tester in metal foil

- 3Plastic film folding resistance testing by folding resistance Tester

- 4How is the folding resistance Tester used for the detection of tissue paper?

- 5Analysis on the Application of Folding Tester in Cardboard

- 6What is the folding resistance of paper and cardboard?

- 7What are the factors that affect folding endurance?

- 8Test method and principle of corrugated cardboard folding resistance meter

- 9FRANK horizontal refractometer test method