Paper and board - Determination of smoothness - Buick method

1 definition

Buick smoothness refers to the time required for a certain amount of air to leak from the atmosphere between the sample surface and the annular surface under a specific contact state and a certain pressure difference, expressed in seconds.

2 principle

The measurement principle of this method is to place a sample on the glass surface, apply a specified pressure, generate a semi-vacuum to absorb the atmosphere, pass through the contact surface, and measure the time required for the vacuum degree to change within the specified range. The longer the time, the smoother the sample.

3 instruments

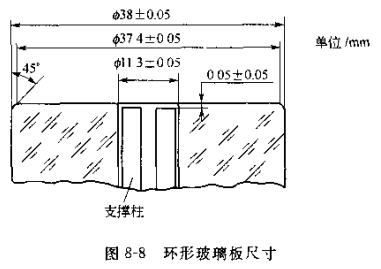

①The glass plate of the Buick smoothness Tester is ring-shaped, and the specifications and dimensions should meet the design requirements of Figure 8-8, ensuring that the effective is (10±0.5) cm²; the test surface should be precisely polished, free from scratches and Cracks should always be kept clean. A support column shall be placed in the center hole of the bad, with the upper surface leveled with the glass plate, so as to prevent the sample from being sucked into the hole. There must be 4 radial slots on the support column for the passage of air.

②The pressure applied to the sample is (100±2) kPa.

③The pressure plate is a circular plate with a flat surface and a diameter of 45 mm, which is in contact with the sample at a fixed pressure.

④ The thickness of the rubber pad is (4 ± 0.2) mm, the maximum thickness change is ± 0.05 mm, the diameter of the circular plate is not less than 45 nm, and the hardness is (40 ± 5) IRHD9 (international rubber hardness).

⑤ Vacuum containers, including large vacuum containers and small vacuum containers. It can be evacuated to 53.35 kPa (approximately 4(0 mm-Hg) and sealed. The large container includes a connecting tube to the glass surface, and its total volume is (380±1) ml. The small vacuum container is also included to the glass surface The connecting tube with a total volume of (38 ± 1)ml.

⑥The working range of the pressure gauge is 50.66 kPa (380 mmHg), 48.00 kPa (360 mmHg) and 29.33 kPa (220 mmHg), and the accuracy is ± 0.07 kPa (about ± 0.5 mmHg). When the vacuum degree drops from 50.66 kPa to 48.00 kPa, it is equivalent to the intake volume of a large vacuum container (10±0.2)ml or the intake volume of a small vacuum container (1±0.05)ml: when the vacuum degree drops from 50.66 kPa to 29.3 .3 kPa, it is equivalent to (80±1) ml (both volumes under normal pressure) of the large vacuum container.

The timer can be read accurately to 1s.

4 Calibration of the instrument

(1) Contact pressure calibration According to the difference of the pressurization mechanism of the instrument, use an appropriate method to check whether the contact pressure is equal to (100±2)N.

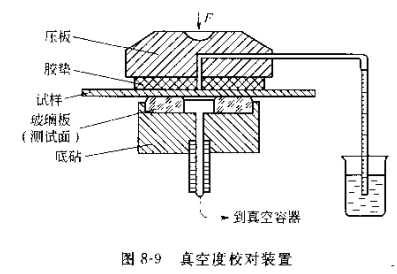

(2) Vacuum calibration adopts the device shown in Figure 8-9. Put a high-smooth paper with a hole in the middle on the glass anvil of the instrument, put a rubber pad with a hole in the middle on the paper, and put a rubber pad on the rubber pad. Special proofreading block. Connect a mercury manometer externally. Pump the vacuum volume of the instrument to 53.35 kPa, and the mercury manometer indicates 400mmHg. When the pressure drops to 50.66 kPa, the vacuum pressure indicator of the instrument should indicate the same value as that indicated by the external vacuum manometer. Otherwise, the instrument should be calibrated.

(3) Calibration of the tightness of the instrument Press the rubber pad directly on the glass anvil with a pressure of 100 kPa, and pump the vacuum to 50.66 kPa. When the vacuum container is connected to the glass plate, the vacuum degree of the large container is 60 nin or the small container is 60 nin. The decrease within min cannot be greater than 0.13 kPa, otherwise both containers should be calibrated.

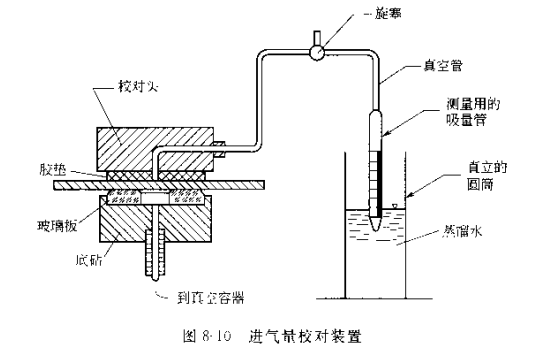

(4) Calibration of air leakage. The measuring instrument is shown in Figure 8-10. A rubber pad with a small hole with a diameter of about 0.5 mm is placed on the calibration head, and it is pressed against the glass plate with a pressurizing device. The calibration The head is connected to the three-way cock with a vacuum tube, and the three-way cock can be connected to a suction tube of appropriate size and scale by a vacuum tube.

After the tightness check of the measuring device, before the reading, immerse the measuring pipette in the upright circle to a level approximately equal to the level in the measuring device. The drop in vacuum when measured is measured by the volume of distilled water that is pressed into the pipette and immersed. Simultaneously the drop in vacuum of the corresponding vacuum container is measured. The aspiration arm can be emptied with the three-way cock after the measurement.

(5) Calibration of the air resistance of the connecting pipe When the vacuum container is connected to the hole of the uncovered glass plate, the vacuum will drop from 50.66 kPa to 29.33 kPa within 2 seconds. If there is a small container, it should be calibrated at the same time.

(6) The rubber pad The rubber pad should be replaced regularly, and its validity period is generally three months to one year.

5 Sample collection, preparation and processing

① Carry out sampling according to the standard method.

②Cut 10 sheets of 50mmX50mn samples on the front and back of each side at a distance of 15mm from both sides of the paper along the banner, and ensure that there are no wrinkles, cracks or other paper defects on the sample surface .

③The sample should be treated with temperature and humidity according to the standard method.

④ Test under standard temperature and relative humidity conditions.

6 test steps

① When testing a certain side, place the surface to be tested close to the surface of the glass plate, and note that it is not allowed to measure two sides of a sample. Then place the rubber pad and the upper platen on the sample, apply a pressure of (100±2) kPa, and generate a vacuum of 50.66 kPa in the vacuum container. Measure and record the time required for the vacuum degree to drop from 50.66 kPa to 48.00 kPa, expressed in seconds. This time is first tested with a large volume. If this value is greater than 300 s, use a small volume and repeat the test with another sample. If this value is less than 15 s, use another test sample to test the time required for the vacuum degree to drop from 50.66 kPa to 29.3.3 kPa. The time from the loading of the sample to the start of measurement should be about 60 s.

② After measuring one side, use another 10 test pieces to measure the smoothness of the other side.

7 Calculation and presentation of test results

The smoothness of the sample surface is the arithmetic mean value of 10 measurement results, represented by s.

If a large vacuum container is used, s is the average smoothness. Such as a small vacuum container. Then the smoothness is 10s.

If the vacuum drops from 50.66 kPa to 29.33 kPa, the smoothness should be s/10.