How to measure the ink absorbency of paper and cardboard?

This method is suitable for white or off-white, coated or uncoated paper and board for lithographic, gravure and letterpress printing.

1 definition

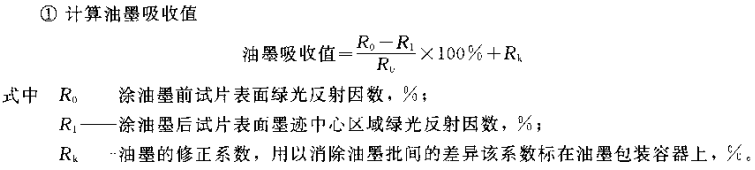

(1) The performance of ink-absorbent paper and paperboard to absorb standard ink within a specified time. The ink absorption value is obtained by dividing the difference between the reflection factor before and after the same surface of the sample absorbs ink by the original reflection factor of the sample.

(2) The ink absorption time is the time required from the beginning of ink application to the time when half of the ink area is wiped off.

2 principle

The ink absorption performance is expressed by measuring the reduction of the surface reflection factor R of paper and paperboard after absorbing non-drying ink on the collimated product of the cup within a specified time.

3 instruments

(1) Ink absorption Tester (see Figure 8-17) The instrument should be designed to be able to uniformly coat a layer of about 0.1 thick on the [(20±0.4) cm2], square or circular area of the specified size sample. mm of absorbent ink, and can wipe off the unabsorbed ink with ink-wiping paper according to the specified ink absorption time, leaving ink marks with uniform color tone on the sample. The Tester should also be equipped with the following spare parts or accessories: special ferromagnetic ink scraper; ink scraper; standard absorbent ink; ink wiping paper.

Note: It can be ordered from Tianjin Paper Technology Research Institute.

(2) The geometrical conditions and spectral characteristics of the reflectance photometer should comply with relevant regulations.

(3) Chronograph resolution 0.1s.

4 calibration

① Verification of the average speed of the ink wiping table.

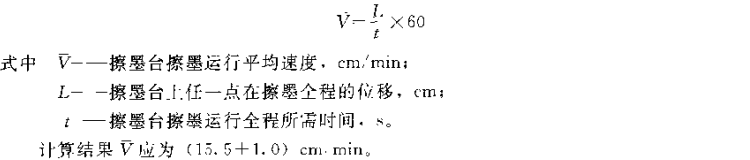

Use a chronograph stopwatch with a resolution of 0.1 s and a steel ruler with a range of 30 cm to measure the time Lt and the displacement L of any point on the ink-wiping table for the entire process of wiping the ink. Calculate as follows:

②Verification of ink absorption time. Put the time control switch in the "automatic" position, draw the ink outline with a pencil at the position where the test piece is to be inked. Put the test piece on the ink wiping table. Use the above-mentioned chronograph to record the time from the beginning of applying ink to the ink-wiping fan-shaped body on the test piece: the outline of the ink trace drawn with a pencil--half the time required (s). The automatic control mechanism digs the ink absorption time. The average value of 5 calibrations should be (120-5)s.

③Validation of the thickness of the smear platen. Use the lower ruler to measure the ink-coated platen, take the arithmetic mean of the measurement results, and the thickness should be 0.10-0.02mrn.

④ Calibration of the hole ruler in the center of the ink platen. Use a vernier caliper with a division value of 0.02 mm and a range of 200 mm to measure the size of the opening in the center of the inking platen, and calculate the square or circular area value. Its opening area is (20±0.1) cm2.

⑤ The surface of the ink-coated glass backing plate of the daily test should be flat.

⑥ Automatic timer calibration of the instrument. Use a chronograph stopwatch with a resolution of 0.1 s to verify the automatic timer, and the average value of the 5 verification results should meet (120±5>s.

5 test steps

①According to standard methods, take samples, process samples, and test under standard conditions.

② At a position more than 15 mm away from the edge of the flat paper and roll paper, cut a sufficient number of rectangular (65 ± 2) mmx210 mm samples to ensure that the tested surface (the front of the paper and cardboard used on one side and the front of the cardboard used on both sides) Paper and cardboard front and back) There are not less than 5 available test pieces. The long side of the test piece is the longitudinal direction of the test material. Each test piece should be stacked face up to form a stack, and each stack should be lined with a test piece at the top and bottom for protection.

③ Each instrument shall be inspected, preheated and calibrated according to the requirements of the factory manual.

④Use a reflectance photometer to measure the green light reflection factor R, before the surface of the sample is coated with absorbing ink. The test piece should be lined with several layers of the same material test piece until it is opaque. Test no less than 5 test pieces in turn.

⑤ Apply absorbent ink to the test piece soil with known reflection factor R with an oil absorption Tester. Take a test piece and place it under the inking platen. The tested surface of the test piece is upward, the long side is parallel to the front and rear direction of the instrument, and the center line along the long side direction should be aligned with the center of the opening of the ink platen. Stir the absorbent ink evenly, take an appropriate amount on the ink-coating platen, and distribute the ink evenly on the test piece through the special ferromagnetic ink scraper and the opening of the platen to form a square with an area of 20 cm2 and a thickness of 0.1 mm or Round ink film. Wipe off the unabsorbed ink with the ink-wiping paper clamped on the sector of the instrument, leaving 20 cm2 of ink on the test piece. The automatic ink wiping operation should ensure that the average ink absorption time is 2 minutes. Manually operated with a chronograph stopwatch.

Note: The ink absorption time can be selected as required, but it needs to be indicated in the test report. The arbitration requires 2 minutes of ink absorption time.

⑥In order to prevent the ink marks from changing due to the influence of the external environment, measure the green light reflection factor R in the central area of the ink marks on the test piece with a reflection photometer immediately after wiping the ink. The backing material is an uninked test piece of the same material.

⑦ Repeat steps ⑤ and ⑥ to prepare no less than 5 test pieces in sequence.

6 Calculation of results

Calculate the ink absorption value of each test piece separately, and then calculate the arithmetic mean of 5 results. The result is rounded to an integer number of digits.

Calculate the coefficient of variation of the result, accurate to the second decimal place.

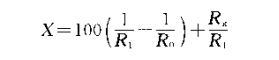

②In order to exclude the influence of paper brightness on the ink absorption value, the ink absorption index X can also be used to represent the ink absorption performance of paper and cardboard, and its calculation method is as follows:

The symbols in the formula have the same meaning as above.