Paper and paperboard - Determination of water absorption - Cobb method

1 definition

Water absorption on the surface of paper and cardboard (Cobb value) refers to the amount of water absorbed by the surface of paper and cardboard per unit area under certain pressure and temperature within a specified time, in g/m'.

2 principle

Weigh the mass of the sample before starting the experiment, and then let one side of the sample contact with water for a certain period of time under standard temperature and pressure. Then blot up the water adsorbed on the surface of the sample and weigh it. The increased mass of the sample is the water absorption. Usually the test area is l00 cn2.

3 Instruments and reagents

① Kebo Absorption Tester. The instruments used in the test shall meet the following requirements.

a. The inner cross-sectional area of the metal circle is (100±0.2) cm2, the corresponding inner diameter is (112.8±0.2) mm, the height of the cylinder is 50mm, and the contact part between the annulus of the circle and the sample should be smooth.

b. In order to prevent water leakage, a layer of elastic but non-absorbent rubber pad or gasket should be added to the cover of the instrument cylinder.

② The test should use distilled water or deionized water. During the test, the temperature of the water should be maintained at (23 ± 1) °C in relation to the temperature of the surrounding atmosphere.

③Water absorption device

a. The weight of absorbent paper should be 200~250 g/m2, and its absorption height should be 75 mm/10 min. When the weight of a single layer of absorbent paper is less than 200~~250 g/m2, multiple layers can be stacked to meet the above requirements.

b. Smooth metal flat stick. Mixed width (200 ± 0.5) mm, mass should be (10 ± 0.5) kg.

④ balance. It can be accurate to 0.001 g, and the measuring range should be suitable for weighing the sample.

⑤ stopwatch. Can be read accurate to 1s.

⑥The volume of 100 ml glass is simple.

4 Test preparation

①Sampling according to the standard method.

② Carry out temperature and humidity treatment according to the standard method.

③ Cut the sample into 10 circular specimens of 125 mm × 125 mm or 125 mm in diameter (5 on each front and back), so as to ensure the test of each 100 cm2.

④Test under standard temperature and humidity.

5 tests

① Use a glass measuring cylinder to accurately measure 100 ml of distilled water and pour it into the metal cylinder of the Copper Absorption Tester, and clean the cylinder annulus and the inner surface of the sample gland.

② Place the weighed circular test piece on the circular surface of the cylinder, with the surface to be tested facing the direction of water. And cover the sample gland on the sample ±., so that it is fixed with the cylinder.

③Then turn the cylinder 180°, and start the stopwatch at the same time. After the specified time is reached, straighten the tube immediately, loosen the round slide quickly and put the sample out on a piece of absorbent paper. Note that the absorbent side of the sample is downward. Then put two pieces of absorbent paper on the sample, press it back and forth within 4 s with a smooth press on a flat and hard table, so that the surface of the sample is water-free and smooth, take out the sample and fold it immediately, and fold the wet side on the Inside to avoid moisture evaporation, quickly weighed. Accurate to 0.001 g, note that each sample can only be tested once and cannot be reused. Absorbent paper can be reused many times as long as its absorbency is guaranteed.

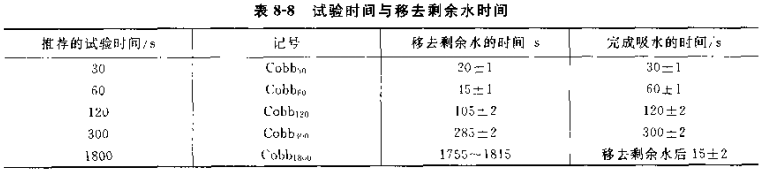

Note: Water absorption time refers to the time from the beginning of contact between water and sample to the end of water absorption. This time can be selected according to the water absorption capacity of paper or cardboard, and is consistent with Table 8-8. The time can be extended or shortened if necessary, but it should be noted in the test report. 10~15 minutes before the end of water absorption, turn tube A upright.

④ For every 5 measurements, add a certain amount of water according to the water absorption of the paper.

⑤ If there is still excess water on the surface after absorbing water with absorbent paper or the sample itself has been penetrated by water, the sample should be discarded. If the cut-off exceeds 20%, the test time should be shortened until a satisfactory result is obtained. But the shortest test time should be 10 s.

6 Calculation of test results

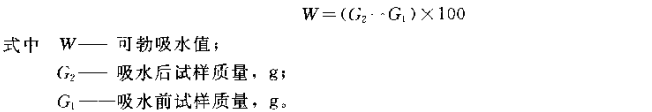

The test results are calculated according to the following formula, expressed in g/m2, accurate to one decimal place.

- 1Effect of water-absorption energy on the performance of Spreader paper

刘金刚;彭建军;王比松;苏艳群 - 《预涂纸的吸水性能对涂布纸性能的影响 》