Cardboard - Determination of puncture strength

1 definition

Puncture strength refers to the work required to pass through the cardboard with a pyramid of a certain shape, that is, including the work required to start puncturing and make the cardboard tear and bend into a hole, expressed in kg cm (J). This method is applicable to various types of cardboard such as boxboard, corrugated boxboard and the like.

2 instruments

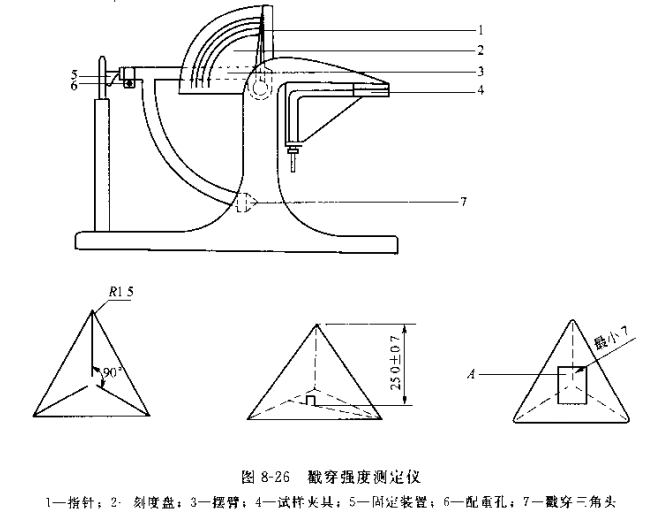

① The puncture strength should be measured with a Beach puncture strength Tester (as shown in Figure 8-26) that meets the following requirements. The instrument generates impact by means of a pendulum cone. The platform of the instrument rack should be firmly installed on a solid foundation to avoid energy loss, and the instrument should be placed in an accurate horizontal position so that it cannot vibrate during the test.

②The pendulum is equipped with an arm in the shape of a 90° circular arc, on which a pyramid is mounted. The pyramid should be a regular triangular pyramid with a height of (25±0.7) mm and a radius of rounded edges of 1.5 mm. One of the bases of the pyramid should be parallel to the axis of rotation of the pendulum, and the opposite corner of the base should point towards the axis of rotation.

③Plywood device. In order to fix the sample, there are two horizontal splints, the upper splint is fixed, and the bottom of the upper splint which is in contact with the sample should be at the level passing through the pendulum axis or not higher than 7mm of this level. The effective surface of the splint should not be less than 175 mm×175 mm. There is an equilateral triangle hole in the middle of the splint, the side length is (100±2) mm, the holes of the upper and lower fire plates should coincide, and the radius of the arc at the included angle is 3.0 nm. The minimum force applied between the splints is 250 N (25 kf), but not more than 1000 N (100 kg). If the instrument does not have a device to measure the clamping force, then the force used in the test should be used to ensure that the sample does not loosen.

④ reading pointer and reading plate. The test result should be indicated by the position pointed by the friction load pointer on the reading plate. There are many scales corresponding to the range of work engraved on the reading plate. The marking of the scale should be in kg cm or J (joule). The range of the reading disc is 0~60 kg cm (0~5.89 J), 0~120 kg cm (O~11.77 J), 0~240 kg cm (0~23.54J), 0~480 kg cm ( 0~47.10]) called file. The pointer should be mounted with just enough friction to move smoothly without wobbling.

Note: 1kg cm=0.098J.

3 Adjustment and calibration of the puncture strength Tester

① For any range of measurement, when the center of gravity of the pendulum is at its lowest point, the tip of the pyramid shall be within ± 5 mm of the horizontal axis passing through the pendulum's axis of rotation. If it is not within the allowable range, adjust the lifting balance.

② Adjustment of zero point. Remove the heavy thallium and the sample splint on the pendulum, then turn the pointer to the maximum value, place the pendulum at the start test position, press the release button, and the pendulum will swing. At this time, the pointer must point to zero, otherwise use the pendulum to Adjust the zero point adjustment screw . When replacing heavy thallium with different weights, the zero point needs to be calibrated again.

③Adjustment of pointer friction. Put the pointer at the zero point, lift the pendulum to the test start position, press the release button, and the pendulum will swing. At this time, the pointer must not exceed 3mm from the zero point, otherwise lubricate the pointer bearing with oil or relax the pressure adjust.

④ Calibration of pendulum friction. When no heavy thallium is added, the released pendulum swings freely until it stops, and the number of swings should not be less than 100 times.

⑤ Calibration of the resistance of the anti-friction ring. After the zero point of the pointer is adjusted, place an aluminum plate with an equilateral triangle hole with a side length of 61 mm in the middle , align the hole of the plate with the hole of the sample pressure plate, press it in the middle of the pressure plate, and then release the puncture of the fixed anti-friction ring: Check the resistance of the anti-friction ring, which should not be greater than 0.88 kg. cm (0.078 J). If it does not meet the requirements, adjust the three top ball screws on the triangular puncture head to increase or decrease the pressure of the spring to adjust.

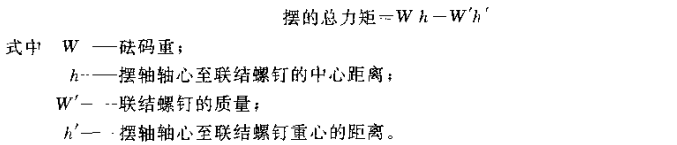

⑥ Calibration of the total moment of the pendulum. Add a small shaft to the back end of the balance weight hole of the pendulum body, install a vertically downward screw at the end of the small shaft, put the pendulum body at the position to be released, and the lower end of the screw is against one end of the balance (or against the scale pan top), release the pendulum, and add a weight to the other end of the balance until the upper plane of the pendulum body is parallel (that is, the balance reaches balance), the total moment of the pendulum is calculated by the following formula;

4 Test steps and result calculation

① Carry out sampling according to the standard method.

② Carry out temperature and humidity treatment according to the standard method.

③Cut out 175 mm×175 mm samples, not less than 8 pieces.

④ Place the sample between the splints and apply a fixed force to the clamp. The sample should be clamped between the positive towels. If the measuring device is equipped with a clamping force measuring device, the force can be recorded. Adjust the pendulum and add weights when necessary to select the appropriate range of work, which will keep the obtained test results within the range of 20% to 80%.

⑤ Put the anti-friction ring on the back of the pyramid, turn the pointer to the highest scale value, lock the pendulum at the test start position, press the release button, the pendulum will swing, and the pyramid will pass through the sample completely, from the corresponding The reading on the scale is equivalent to the total amount of work used to puncture the sample and overcome the friction of the measuring device, accurate to 1 division. If the measurement range of the scale reading is 122.4 kg cm (12J), it should be accurate to 1 kg cm (0.1 J); if the measurement range is above 122.4 kg cm (12J), it should be accurate to 2 kg cm (0.2J). ). If the friction effect is greater than or equal to 1%, the test result shall be compensated by pre-determining the work loss caused by equipment friction.

⑥ In each packaging unit, cut 8 samples from different paper samples taken out. Half of the samples shall be measured longitudinally parallel to the swing plane of the pendulum, and the other half of the samples shall be measured transversely parallel to the swing plane of the pendulum. When the longitudinal direction is parallel to the swing direction of the pendulum, the measured value is called longitudinal puncture strength. The determination result is expressed as the arithmetic mean of all determinations on the front, back, longitudinal and transverse sides, and the maximum and minimum values are reported. The calculation result is accurate to 0.1 kg · cm. For example, when expressed in J, the value is less than 12J, accurate to 0.1J, and the value is greater than 12J, accurate to 0.2J.

- 1Working principle and test method of puncture strength Tester

- 2How to use YT-PRT48 Penetration strength Tester?