How to measure orange peel on coated surface?

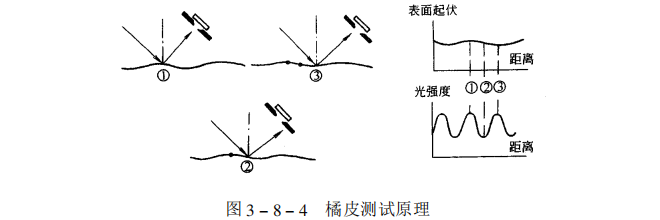

Orange streaks are ripples on the surface of the coating similar to orange peel, which have a lot to do with the surface roughness of the substrate, the leveling of the coating and the construction process. In the past, the severity of the orange peel was determined by visually observing the size of the orange peel, but now a laser orange peel instrument is used to scan the surface ripples (see Figure 3-8-4).

The laser is irradiated to the surface to be measured at an angle of 60°, and the reflected light is measured through slit filtering at the other side at an angle of 60°. During the measurement, the instrument moves a distance of 10cm on the surface to be measured, and emits 1250 laser irradiations for scanning. When the laser shines on the peak or valley, it receives the strongest reflected light; when it shines on the wave slope, the reflected light is the smallest, and the obtained light shape curve corresponds to the optical profile of the surface corrugation observed by the naked eye. The frequency of the curve is twice the frequency of the mechanical profile curve measured by the roughness meter. Corrugations with a length of more than 0.6mm are counted as long waves, and corrugations below 0.6mm are counted as short waves. The fewer the number of long and short corrugations within a certain distance, the lighter the degree of orange peel. The short corrugation is mainly affected by the roughness of the substrate; the long corrugation is mainly caused by the construction process. There are often great differences in the degree of orange peel between the horizontal plane and the vertical plane, and between the plane plane and the complex plane. When testing, several points should be selected in different areas, and the control indicators are also different. For example, a large automobile factory stipulates that the long wave <4 and short wave <20 in the plane area; the long wave <15 and short wave <25 in the vertical area.

- 1Types, applications and evaluation methods of levelling agents

- 2Working mechanism and selection considerations of anti-shrinkage agent

- 3Coating performance testing: leveling & sagging

- 4Coating surface tension and its effects

- 5Coating leveling and sagging

- 6Key Factors and Evaluation Methods of Coating Constructability

- 7Coating performance testing: ensuring the efficiency and mass of the painting process

- 8Coating levelling and sagging performance test

- 9what is the coating Leveling and Sag resistance