Determination of Gelatinization Time of Powder Coatings by Gelatinizer

1. Scope and description

At the curing temperature of the powder coating, the entire gelation time, expressed in minutes or seconds. It is a simple method to evaluate the reactivity and curing reaction speed of powder coatings .

In general, the gelation time is short, the curing is fast, the reactivity is high, and the appearance of the coating film will not be good. On the contrary, the gelation time is long and the curing is slow. If there is not enough baking time, the physical and mechanical properties of the coating film will be deteriorated. not good. This method is not applicable to powder coatings with a gelling time of less than 15s.

2. Instruments and Materials

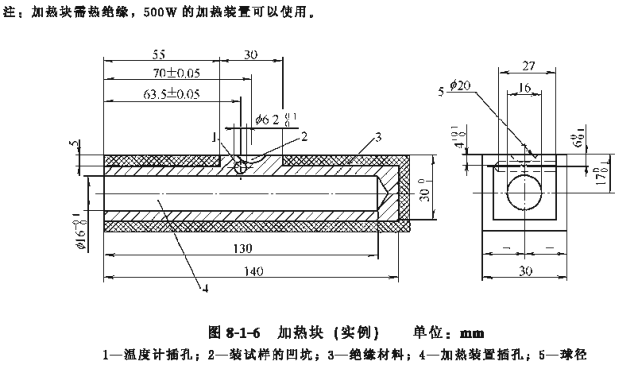

(1) The heating block is composed of an electric heating steel block of sufficient mass (to keep the temperature stable), that is, it should be able to make the change of the selected temperature within the range of 130~230C not greater than ±1C. This temperature shall be controllable with a thermostat. The heating block has a circular polished pit with a diameter of (16 ± 0.1) mm and a radius of curvature of (10 ± 0.1) mm, located at the center of the upper surface for placing the sample to be tested . The heating block should also have a hole of sufficient diameter to place the temperature Detector, which should be close to the center of one side of the heating block, extend horizontally below the upper surface to near the center of the heating block, and its terminal should not exceed 2mm from the center of the pit. Suitable heating The block is shown in Figure 8-1-6.

(2) The temperature Detector should have a sufficient measurement range, and the reading value should be accurate to 1C.

(3) The measuring spoon has a capacity of (0.25±0.01)mL and is used to transfer the sample to the pit of the heating block.

(4) The timer is accurate to 1s.

(5) The agitator is of appropriate size and made of non-thermally conductive material, with a pointed end.

(6) The scraper is made of a material softer than the heating block, and is used to remove the sample on the heating block without scratching its surface.

(7) Check item A test item with a known melting point, used to check the temperature of the heating block. For checking the temperature of 180C, D- camphor is a suitable material.

(8) Release agents such as polytetrafluoroethylene aerosol dispersions.

3. Measurement method

(1) Unless otherwise specified or otherwise agreed by the parties concerned, the test should be carried out at (180±1)C. Place the heating block at room temperature without ventilation, raise the temperature of the heating block to the specified temperature and keep it stable for at least 10 minutes .The surface temperature of the heating block can be checked by placing a small piece of substance with the required melting point on the Heating Plate. If necessary, the pits and the upper surface of the Heating Plate can be treated with a release agent according to the manufacturer's instructions.

(2) Use a measuring spoon to move 0.25mL of the sample to be tested to the pit of the heating block, start the timer immediately after all the samples are melted, and stir the molten material with a stirrer in a small circle motion. When the material starts to thicken, while , raise the stirrer from the melt by about 10mm every 2~3s. If it is raised, the wire formed becomes brittle and breaks and cannot be drawn from the melt. When it is filamentous, stop timing and record the time, accurate to 1s. This time is the gelation time of the sample .

(3) Immediately scrape off the test sample from the heating block with a scraper, taking care not to scratch the surface of the heating block.

4. Result presentation

Resample and repeat the above determination, if the difference between the two test results does not exceed 5% of the minimum value, the arithmetic mean

The value is the last test result, expressed in s, and accurate to 1s.

If the difference between the two measurement results exceeds 5% of the minimum value, a third measurement is required and the arithmetic of the three results is calculated

average value.

5. Reference standard

National standard GB/T 16995 "Determination of gelation time of thermosetting powder coatings at a given temperature".

- 1Gel time meter: Definition, application and scientific selection guide

- 2Determination of thermal plasticity Resin melt flow rate

- 3Molecular weight and distribution characteristics of polyester resin in thermosetting powder coatings

- 4Density Determination Method and Application

- 5Determination method of cone-plate viscometer and its application

- 6Thermal plasticity polyvinyl chloride (PVC) powder coatings in highway engineering: technical requirements and inspection methods

- 7Determination of compatibility of powder coatings: methods, effects and applications

- 8Evaluation of flowability of powder coatings: key factors and significance

- 9Evaluation and Application of Optical Properties of Powder coatings